Lean burn internal combustion engine exhaust gas temperature control

a technology of internal combustion engine and control system, which is applied in the direction of electrical control, machine/engine, exhaust treatment electric control, etc., can solve the problems of relying on a conventional 3-way catalyst to meet emissions regulations, and the difficulty of maintaining adequate exhaust gas temperature in a lean burn engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

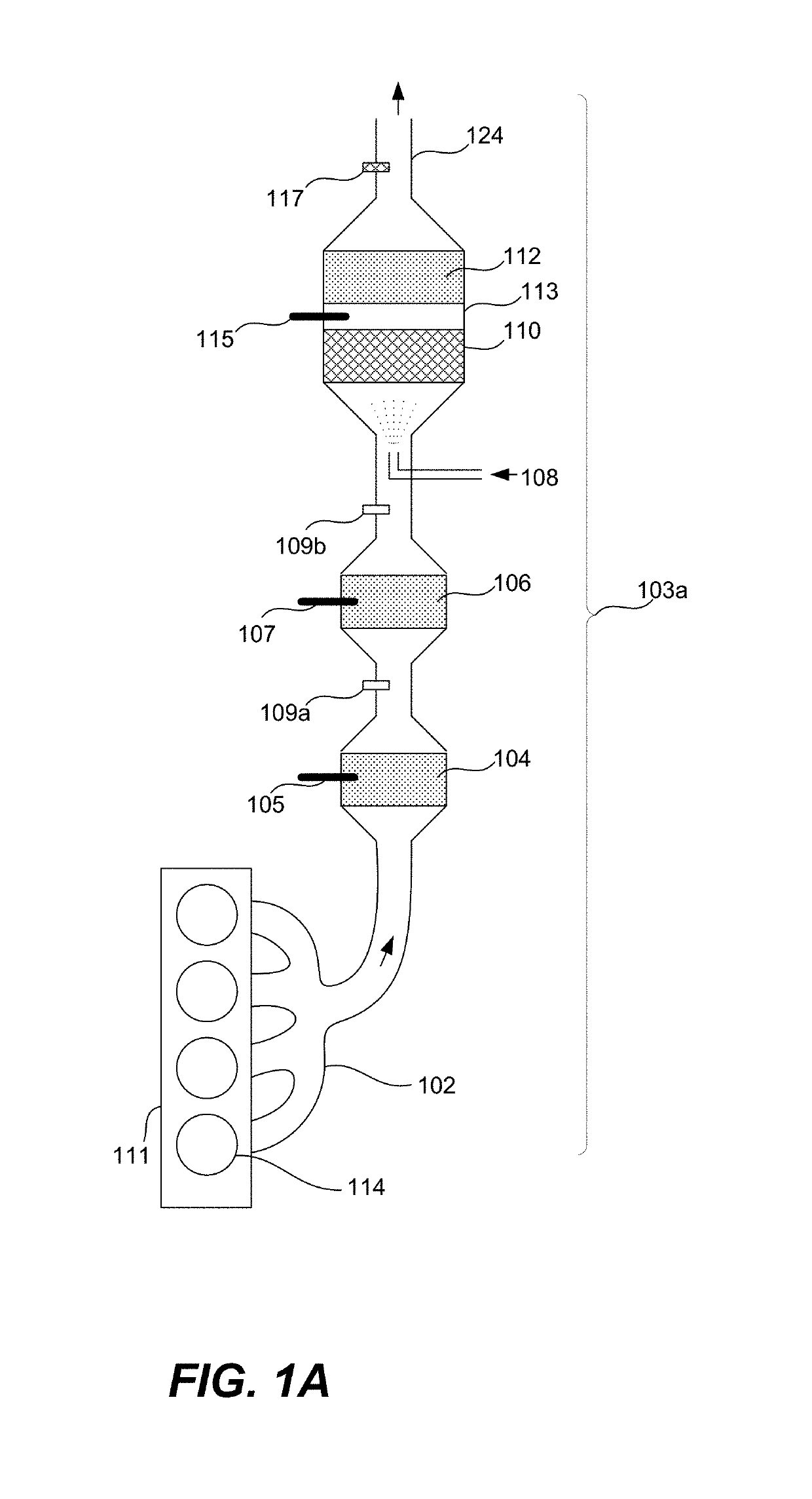

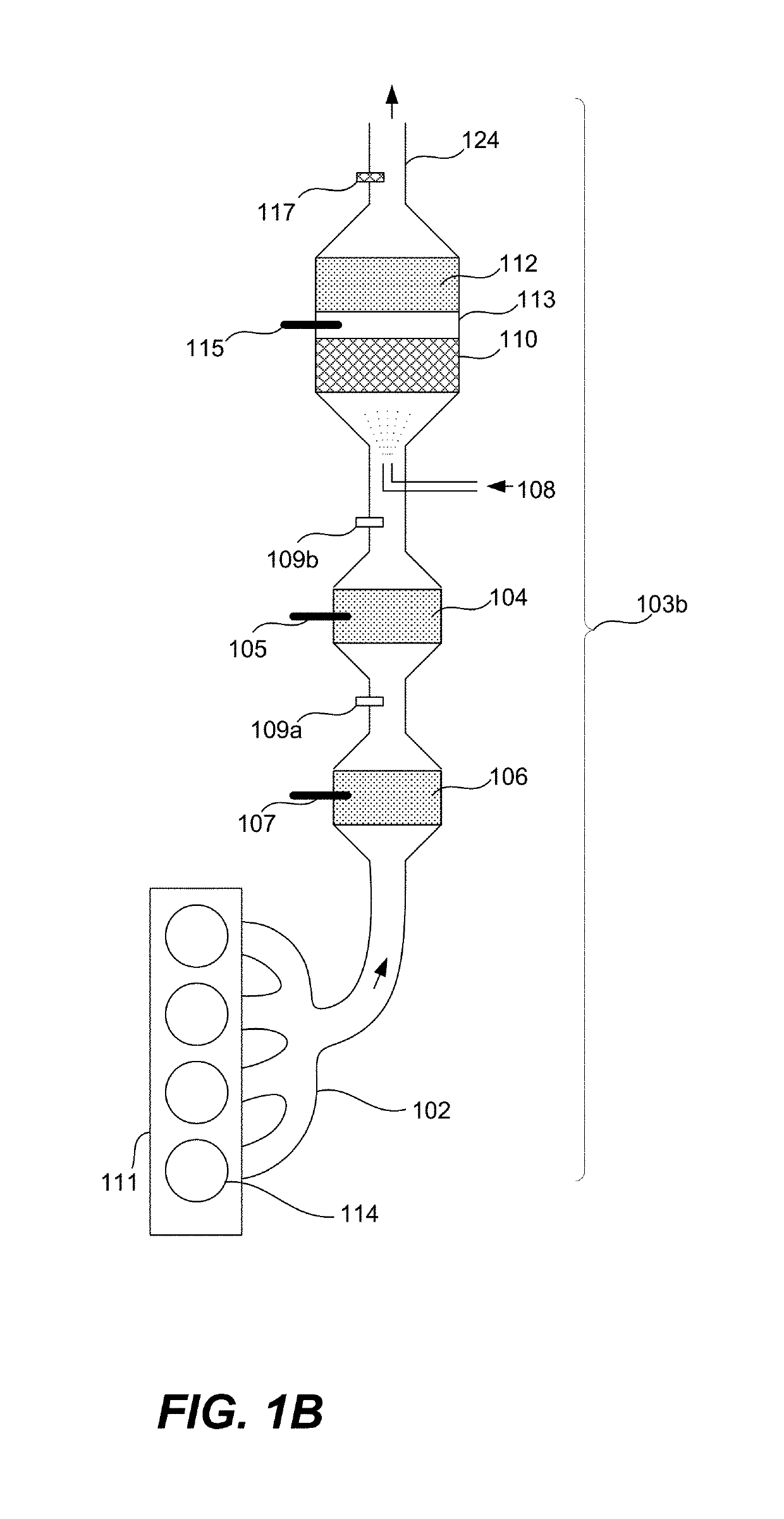

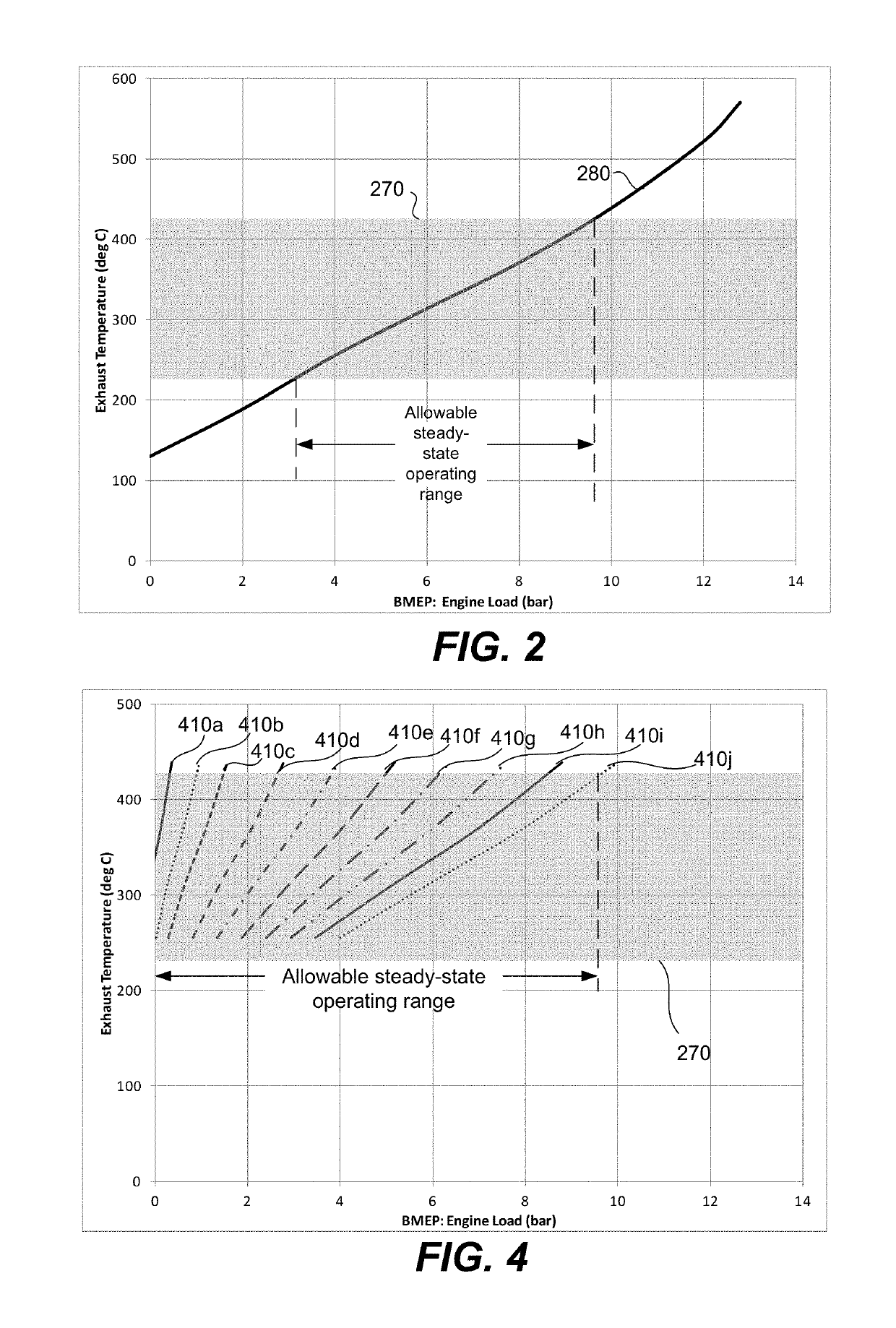

[0022]The present invention relates to a skip fire engine control system for an internal combustion engine—and particularly, lean burn internal combustion engines. More specifically, the present invention relates to arrangements and methods for controlling exhaust gas temperature to improve efficacy of an emission control system. In various embodiments, the firing sequence is determined on a firing opportunity by firing opportunity basis or using a sigma delta, or equivalently a delta sigma, converter. Such a skip fire control system may be defined as dynamic skip fire control.

[0023]Skip fire engine control contemplates selectively skipping the firing of certain cylinders during selected firing opportunities. Thus, for example, a particular cylinder may be fired during one firing opportunity and then may be skipped during the next firing opportunity and then selectively skipped or fired during the next. This is contrasted with conventional variable displacement engine operation in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com