Sliding nozzle

a nozzle and nozzle technology, applied in the field of sliding nozzles, can solve the problems of affecting the quality of steel, the flow pattern and the speed of molten steel discharge, and preventing the discharge of molten steel, so as to suppress the adhesion and deposition of metal oxides, suppress the stagnation of molten steel, and suppress the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

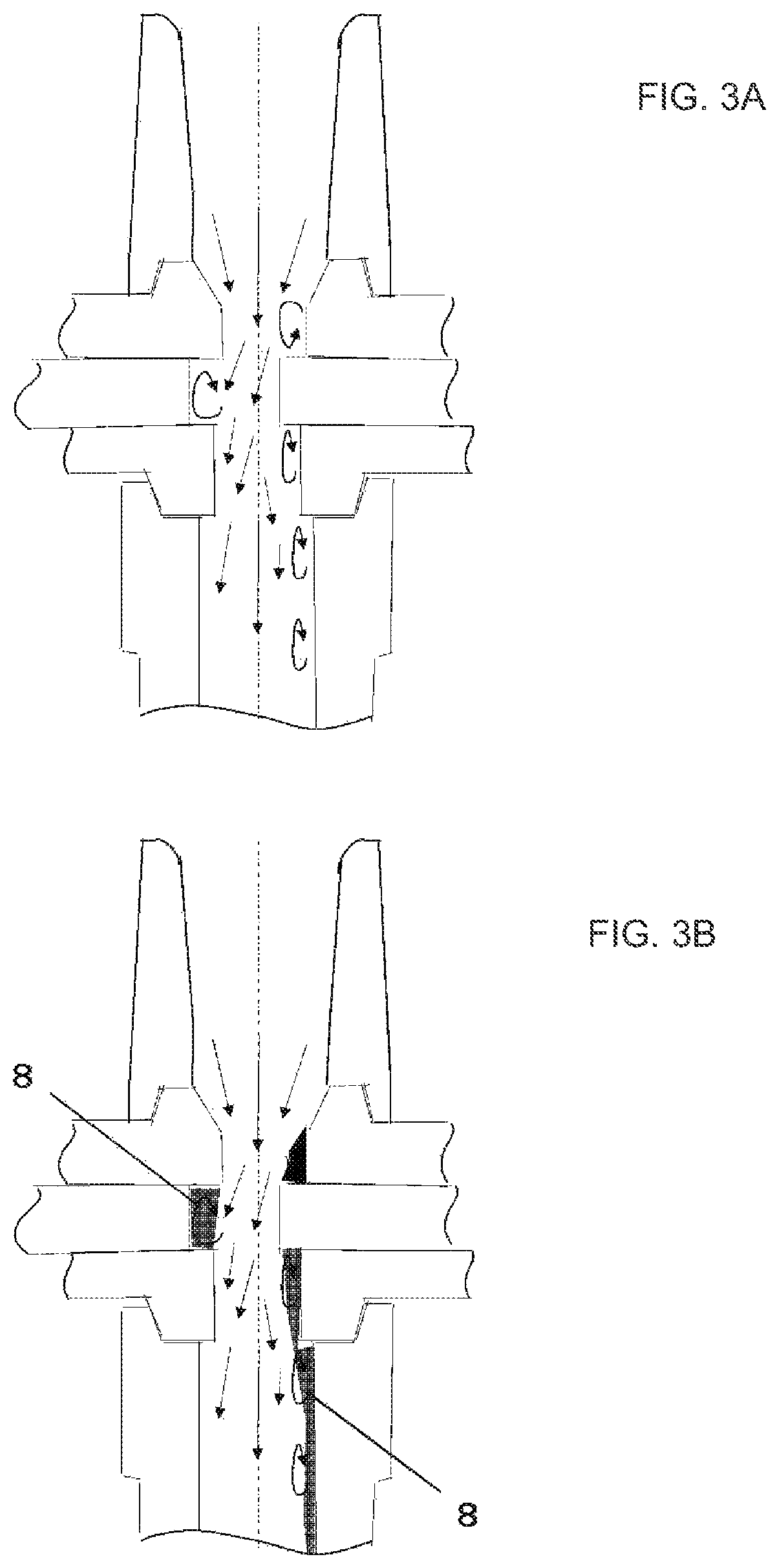

[0042]Experimental examples will be shown and described below. In the following Example A and Example B, with regard to a flow pattern of molten steel, a predominant flow pattern is extracted from knowledge obtained based in simulation and depicted, and, with regard to a state of adhesion and deposition, a typical pattern obtained by observation of a sliding nozzle after being used in actual casting operation is depicted. Further, as a state of the plates depicted in the figures, an open state of the intermediate plate at an approximately constant pouring speed, i.e., at a setup casting speed, is assumed. Further, in the actual casting operation, a refractory member for injecting gas into inner bores was installed to each of the upper nozzle and the upper plate.

example a

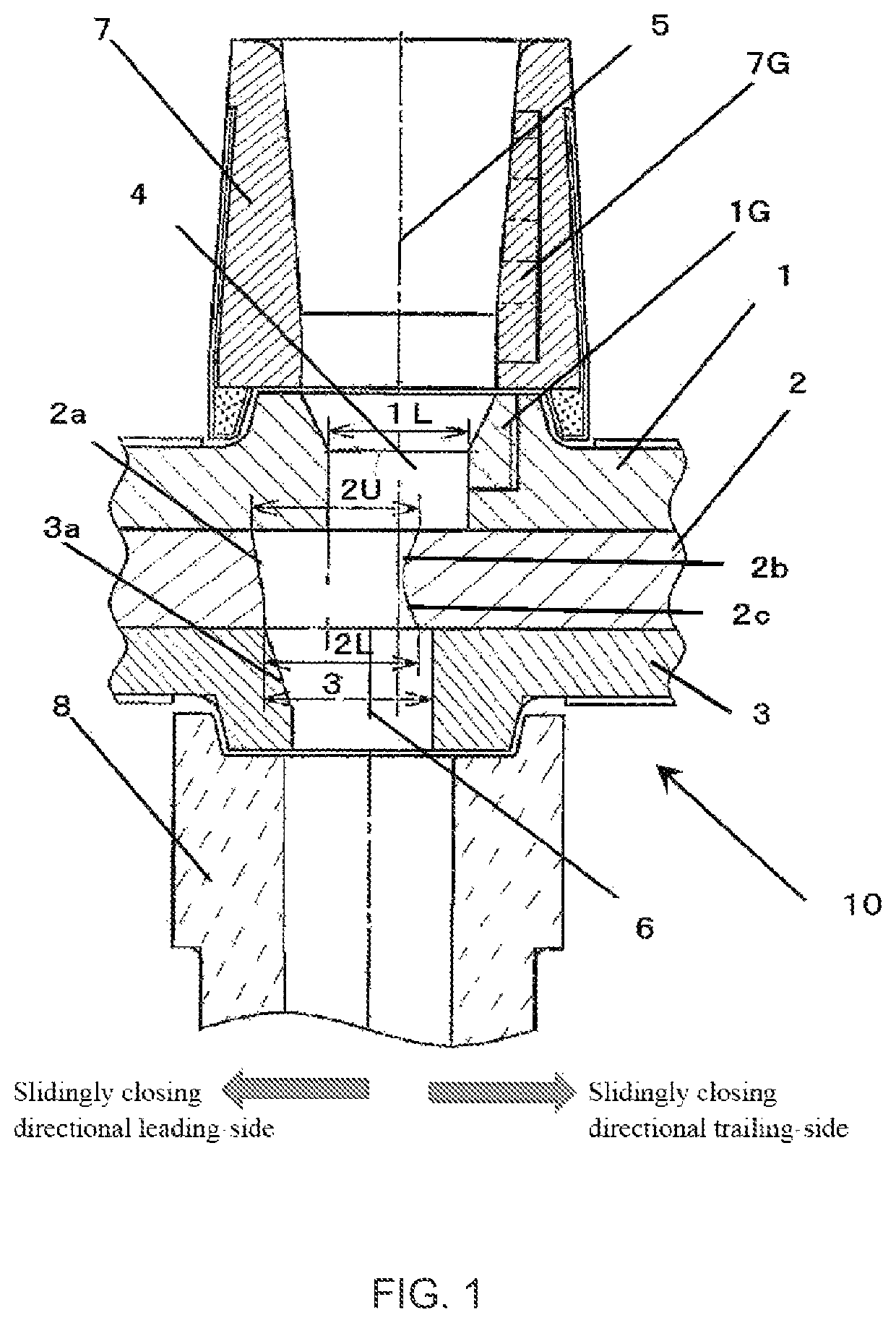

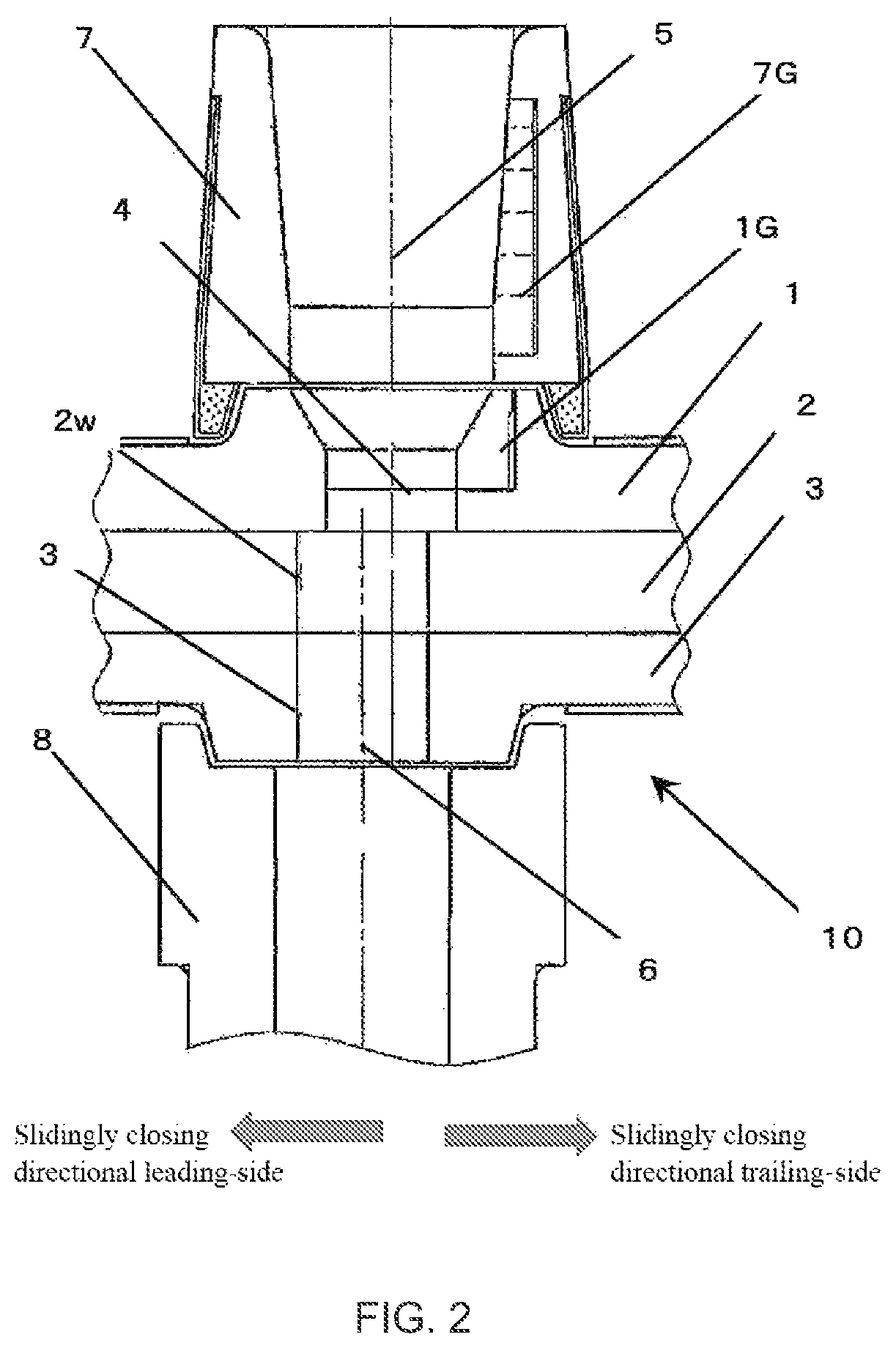

[0043]Example A is an experimental example in which a sliding nozzle configured such that a central axis of an inner bore of an upper plate lies coaxially with a central axis of an inner bore of a lower plate is used to check the flow pattern of molten steel in inner bores and the state of adhesion and deposition of metal oxides and others on inner bore wall surfaces.

[0044]In the actual casting operation, the type of steel was stainless steel containing rare metal such as La and Ce each contained in an amount of 0.1 mass % or less, and the casting speed was 1 t / min or less. These conditions are the same as those in Example B.

[0045]FIG. 3A, FIG. 4A and FIG. 5A are schematic diagrams depicting respective structures of a comparative sample 1 and inventive samples 1 and 2, and FIG. 3B, FIG. 4B and FIG. 5B are schematic diagrams depicting respective states of adhesion and deposition of metal oxides and others on inner bore wall surfaces of these sliding nozzles. FIG. 9 is a graph present...

example b

[0052]Example B is an experimental example in which a sliding nozzle configured such that a central axis of an inner bore of an upper plate lies non-coaxially with a central axis of an inner bore of a lower plate, and the central axis of the inner bore of the lower plate is offset on the slidingly closing directional leading-side with respect to the central axis of the inner bore of the upper plate by 10 mm is used to check the flow pattern of molten steel in inner bores and the state of adhesion and deposition of metal oxides and others on inner bore wall surfaces.

[0053]FIG. 6A, FIG. 7A and FIG. 8A are schematic diagrams depicting respective structures of a comparative sample 2 and inventive samples 3 and 4, and FIG. 6B, FIG. 7B and FIG. 8B are schematic diagrams depicting respective states of adhesion and deposition of metal oxides and others on inner bore wall surfaces of these sliding nozzles. FIG. 9 is a graph presenting a relative relationship of the states of adhesion of meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com