Method and composition for reducing emissions from a gasoline engine equipped with a three-way catalytic converter

a technology of three-way catalytic converter and gasoline engine, which is applied in the petroleum industry, liquid carbonaceous fuels, fuel additives, etc., can solve the problems of high cost and waste, the life of the converter is often less than the life expected of the vehicle in which it is installed, and the converter contains significant amounts of catalytic metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0025] This example is presented to further illustrate and explain the invention and is not to be taken as limiting in any regard. Unless otherwise indicated, all parts and percentages are by weight.

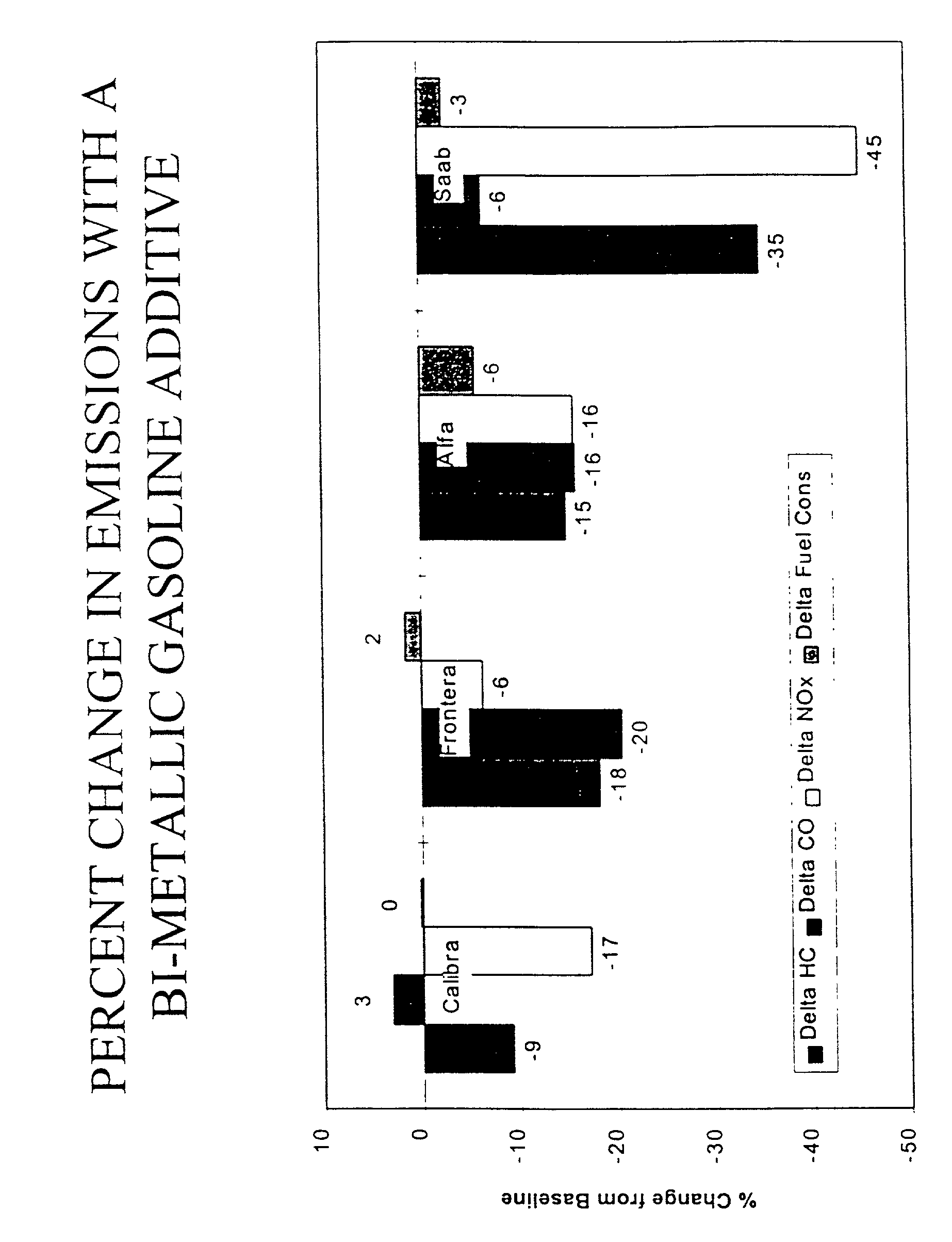

[0026] Four automobiles equipped with three-way catalytic converters were operated on a gasoline composition according to the invention containing rhodium acetylacetonate (0.15 ppm) and diphenyl cyclooctadiene platinum(II) (0.80 ppm). The results are reported graphically in the attached FIGURE.

[0027] Rhodium acetylacetonate is a commercially available material, and is unexpectedly effective when used in combination with a fuel-soluble platinum compound in the composition and method of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| catalyst activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com