Electromagnetic device with embedded windings and method for its manufacture

a technology of embedded windings and electromagnetic devices, which is applied in the manufacture of stators/rotors, magnetic circuit shapes/forms/construction, generators/motors, etc., can solve the problems of affecting the electromagnetic characteristics of stators, affecting the efficiency of manufacturing, and scrap steel pieces, which are often not used productively by manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

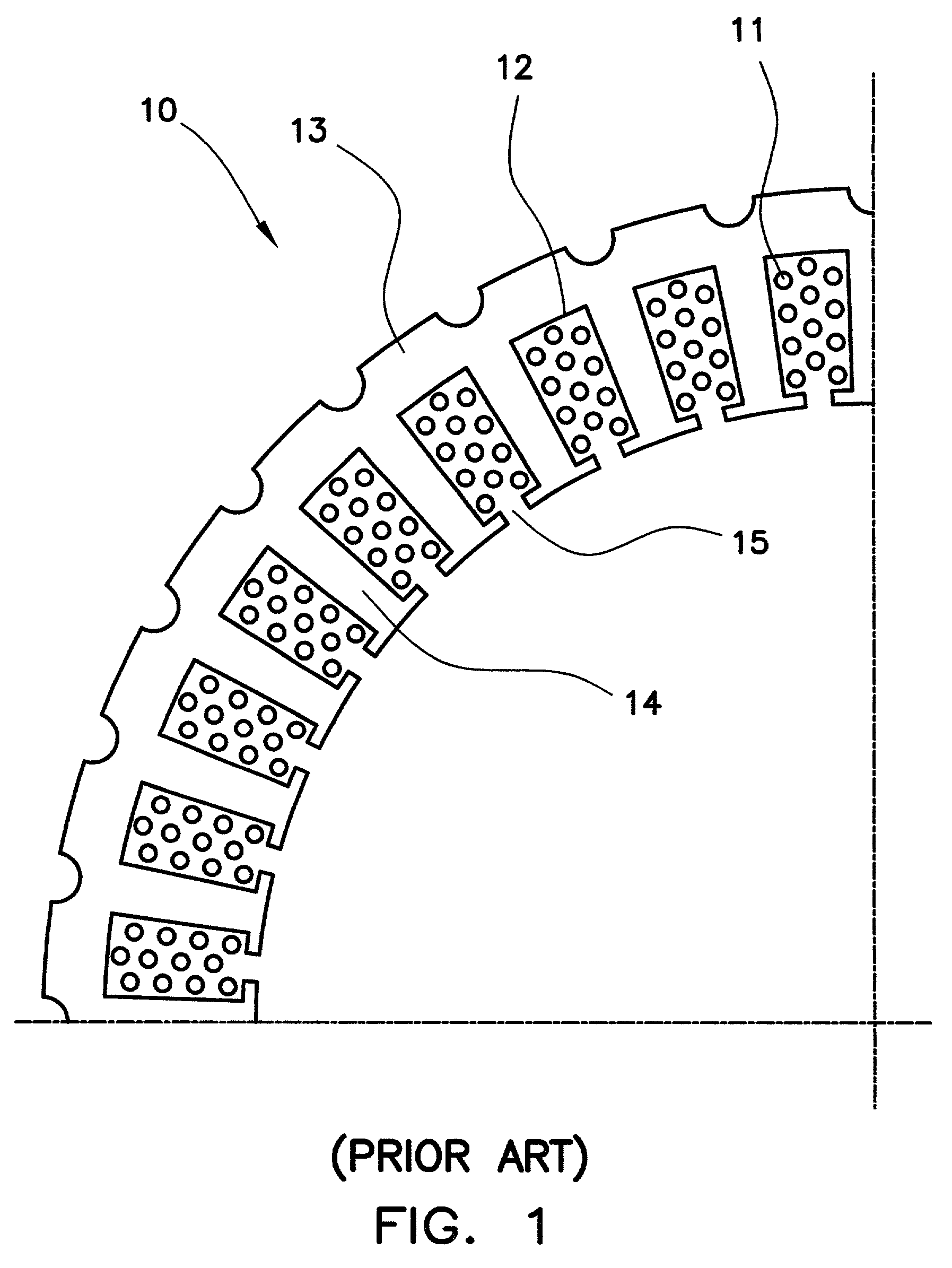

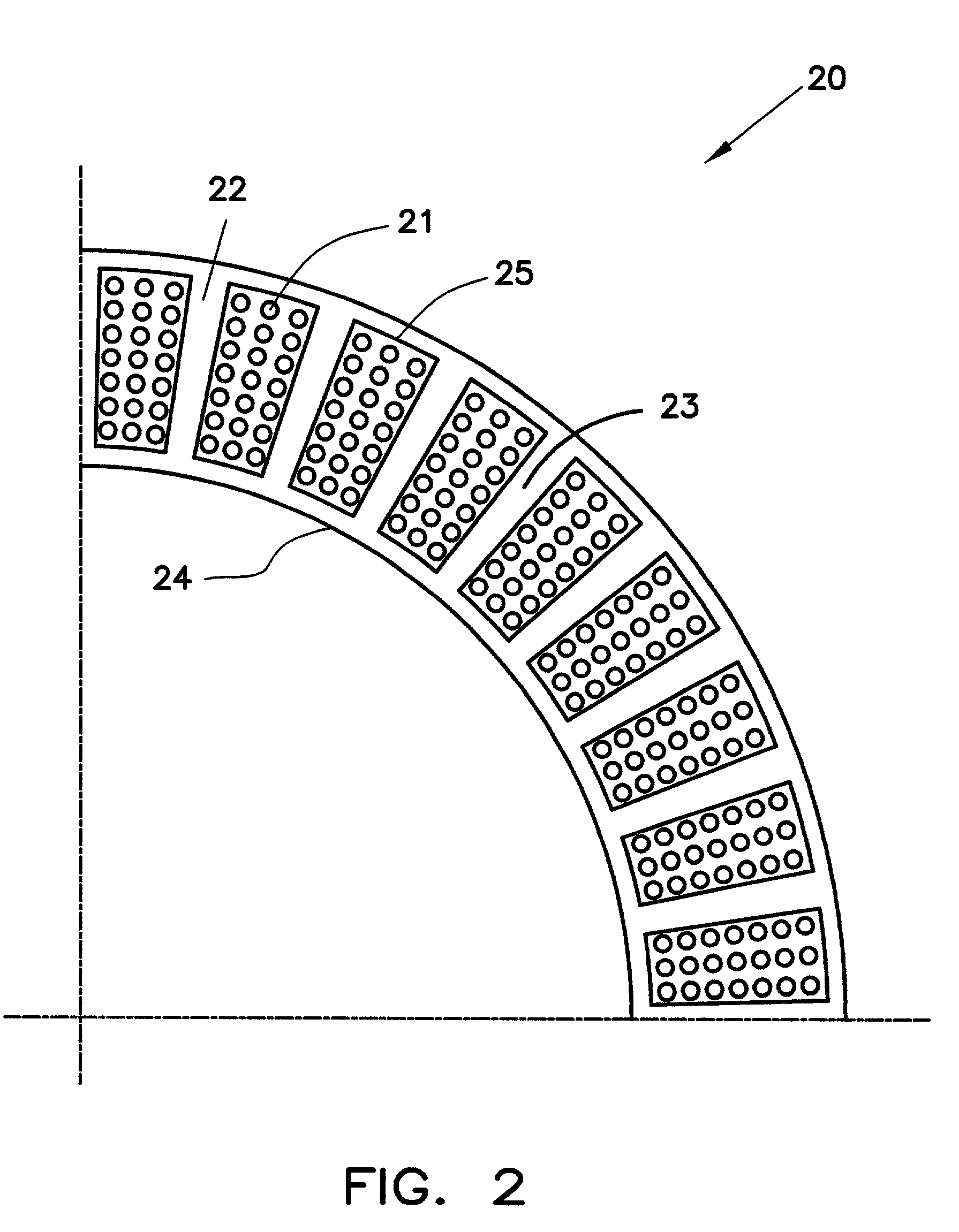

[0036] The present invention is a novel method for manufacturing a stator core from powdered magnetic material, and embedding stator windings within the stator core, and a novel powdered magnetic material stator core with embedded stator windings produced by the method.

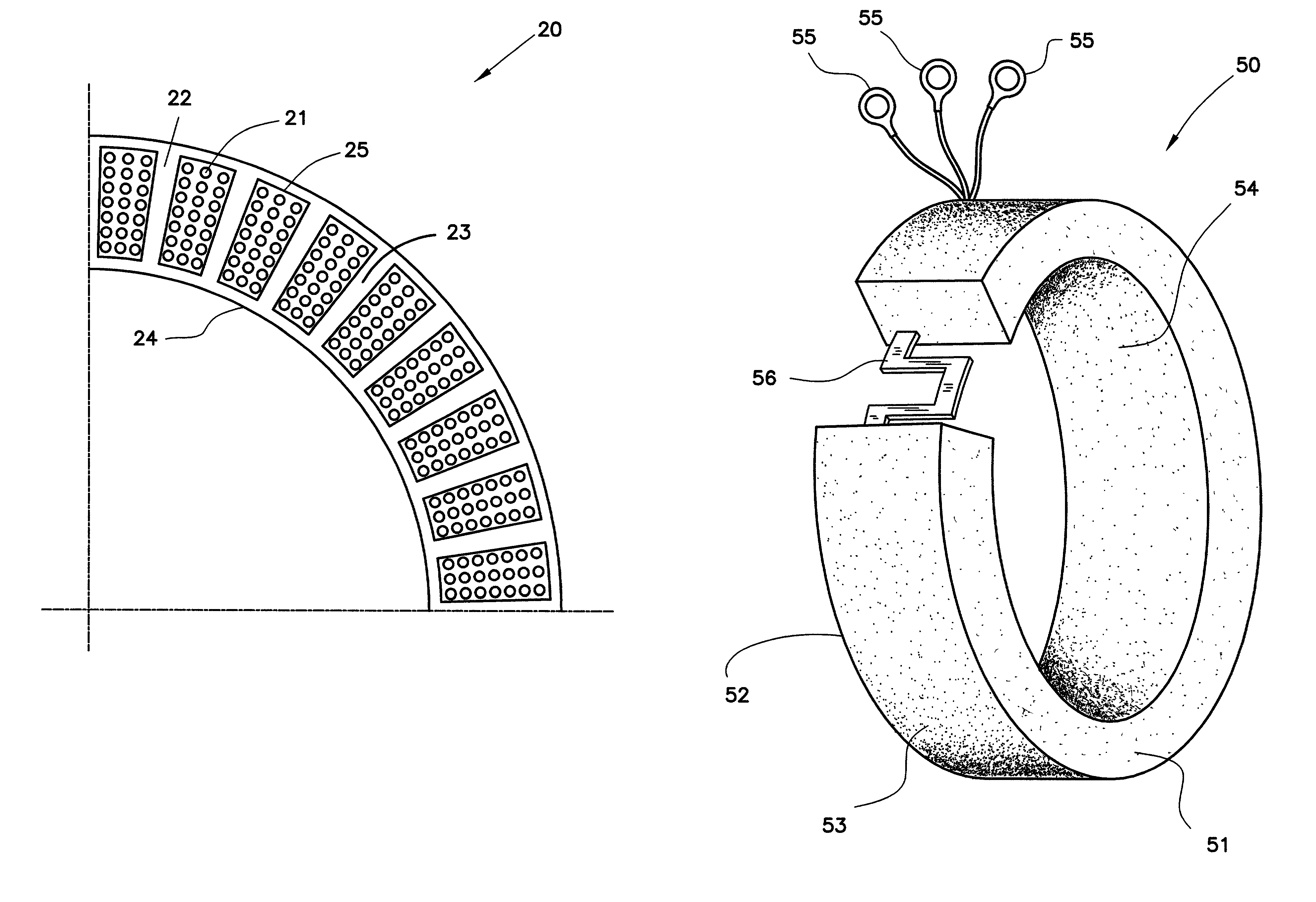

[0037] To better illustrate the advantages of the present invention, it is useful to examine a stator made according to the prior art methods. FIG. 1 shows one-quarter of a cross-section of such a prior art stator. In FIG. 1, stator 10 is shown with a plurality of windings 11 installed in a plurality of slots 12. Stator core 13 is fabricated from a plurality of stacked steel laminations (only the top lamination being shown in FIG. 1). Stator core 13 includes a plurality of teeth 14 which define the slots 12. Windings 11 were shaped into the desired configuration prior to installation into stator core 13. During installation into stator core 13, windings 11 were inserted into slots 12 through slot openings 15.

[0038] FI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com