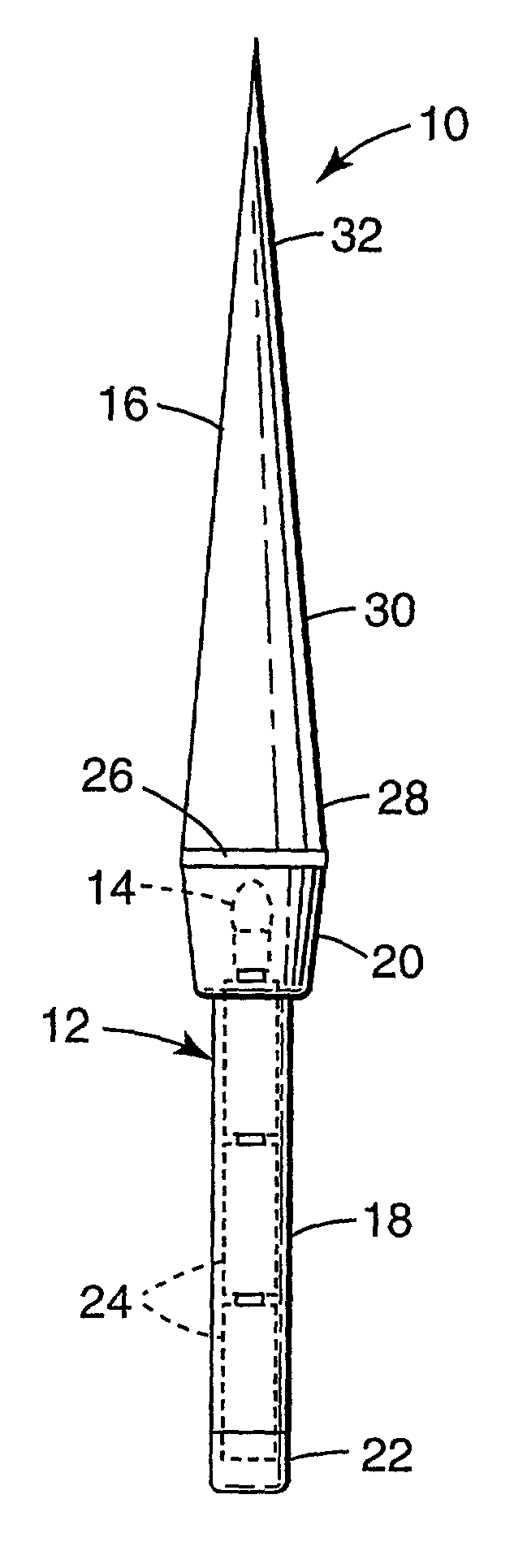

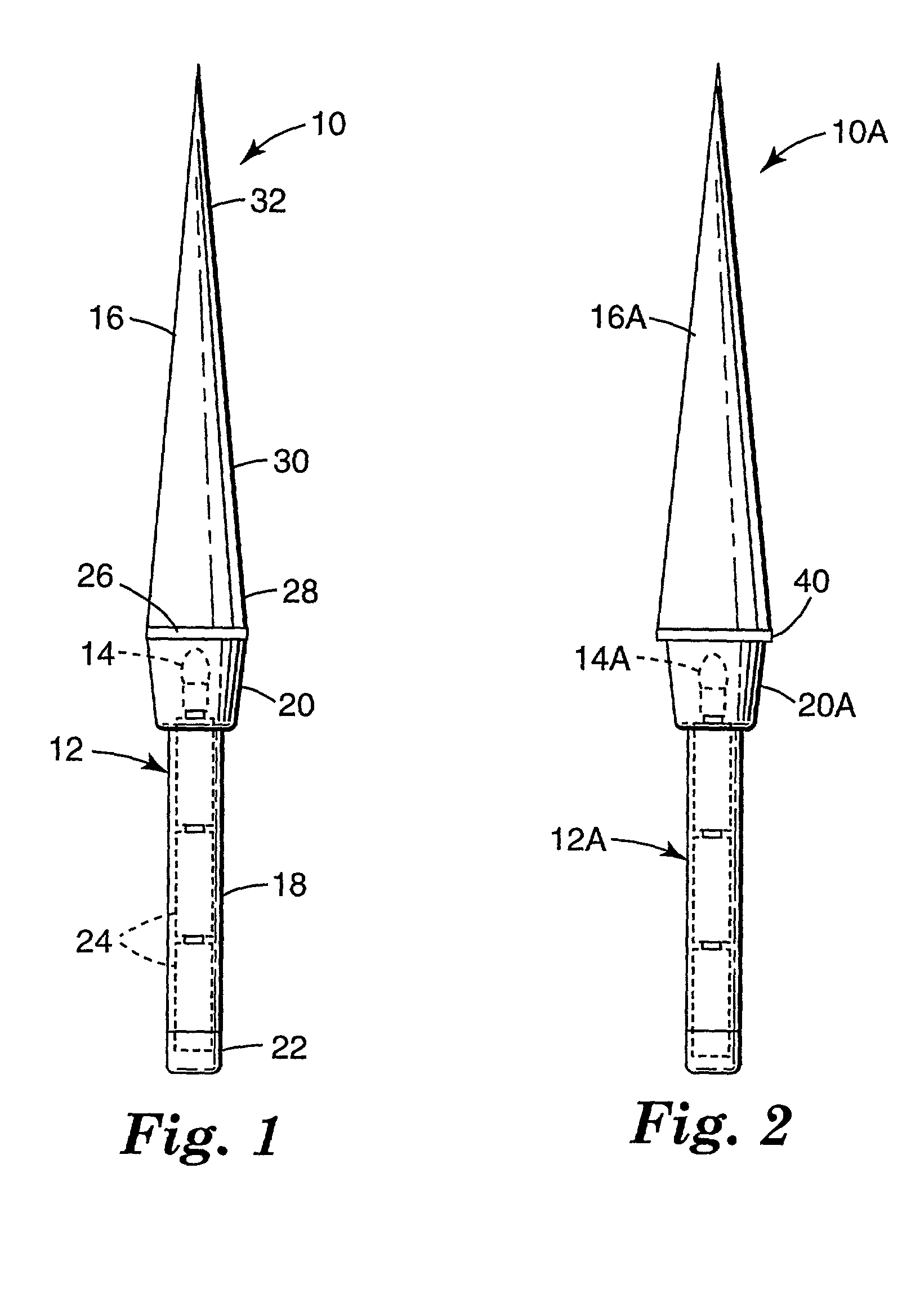

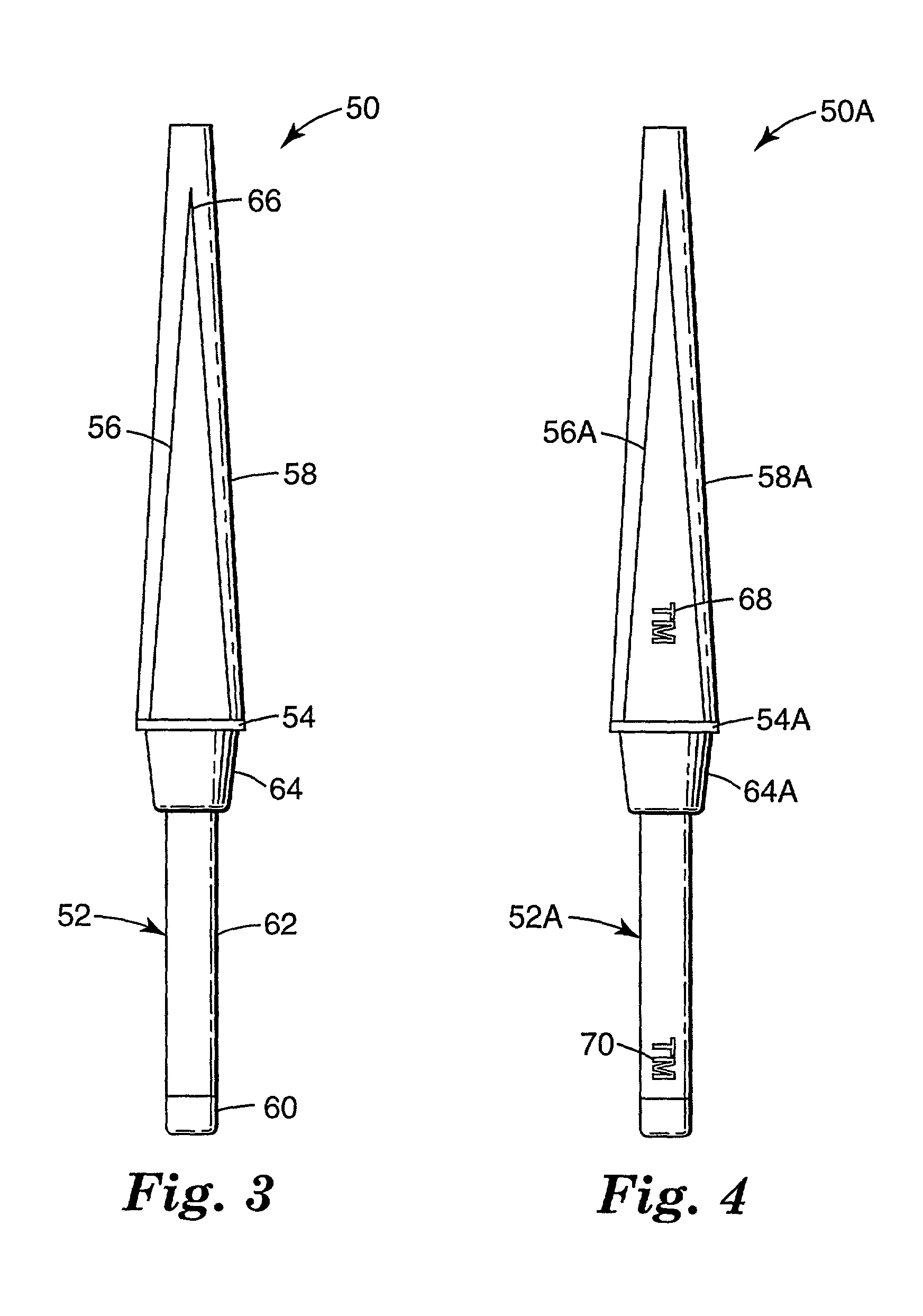

Hand-holdable toy light tube

a toy light tube and hand-held technology, applied in the direction of electric lighting with batteries, electric lighting emission/distribution, lighting and heating apparatus, etc., can solve the problems of inability to produce multiple colors, reduced color purity and/or less dramatic color shifts with angle, and inability to illuminate tubes and fluorescent-colored cylinders to produce multiple colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0113] The following example illustrates the preparation of a another color shifting film.

[0114] A multilayer film containing about 418 layers was made on a sequential flat-film making line via a co-extrusion process. This multilayer polymer film was made PET and polyester resin (available under the trade designation "ECDEL 9967" from Eastman Chemical Co. of Rochester, N.Y.) where PET was the outer layers or "skin" layers. A feedblock method (such as that described by U.S. Pat. No. 3,801,429) was used to generate about 209 layers with an approximately linear layer thickness gradient from layer to layer through the extrudate.

[0115] The PET, with an Intrinsic Viscosity (IV) of 0.56 dl / g was pumped to the feedblock at a rate of about 34.5 Kg / hr and the polyester resin ("ECDEL 9967") at about 41 Kg / hr. After the feedblock, the same PET extruder delivered PET as protective boundary layers (PBL's), to both sides of the extrudate at about 6.8 Kg / hr total flow. The material stream then pass...

example 3

[0121] The following example illustrates the preparation of a visible mirror film.

[0122] A coextruded film containing 601 layers was made on a sequential flat filmmaking line via a coextrusion process. A polyethylene naphthalate (PEN) with an intrinsic viscosity of 0.57 dl / g (60 wt %% phenol / 40 wt % dichlorobenzene) was delivered by extruder A at a rate of 114 pounds per hour with 64 pounds per hour going to the feedblock and the rest going to skin layers described below. PMMA (CP-82 from ICI of Americas) was delivered by extruder B at a rate of 61 pounds per hour with all of it going to the feedblock. PEN was on skin layers of the feedblock. The feedblock method was used to generate 151 layers using the feedblock such as those described in U.S. Pat. No. 3,801,429, after the feedblock two symmetric skin were coextruded using extruder C metering about 30 pounds per hour of the same type of PEN delivered by extruder A. This extrudate passed through two multipliers producing an extruda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com