Optical fiber and method of making the same

a technology of optical fiber and optical fiber, applied in the field of optical fiber, can solve the problems of inability to obtain reliable transmission loss reducing effect, inability to fully realize the reduction of transmission loss in optical fiber, and inability to realize the reduction of transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

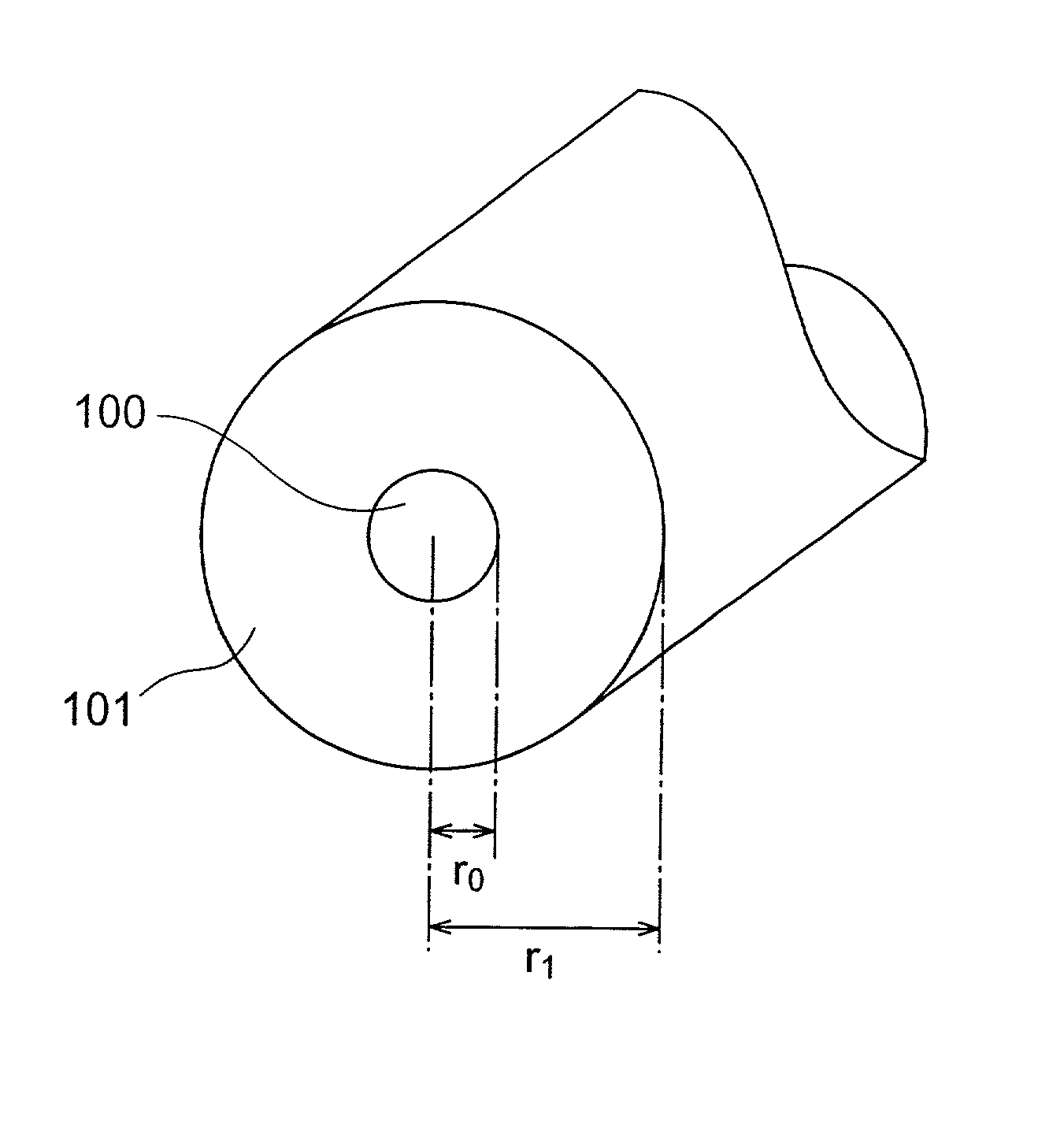

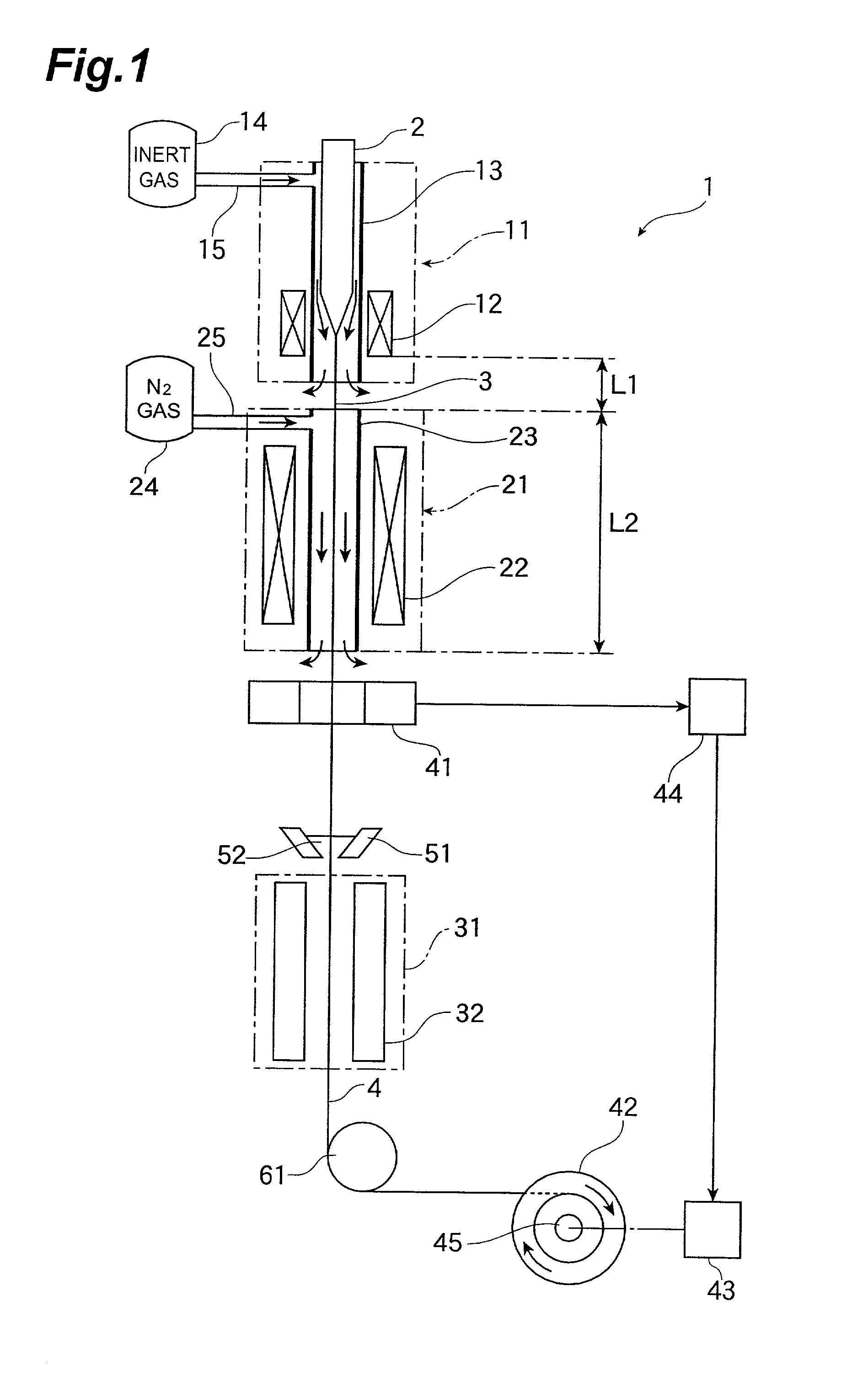

[0125] The configuration of the optical fiber will now be explained. FIG. 7 is a chart showing the refractive index profile of the second optical fiber in accordance with the present invention.

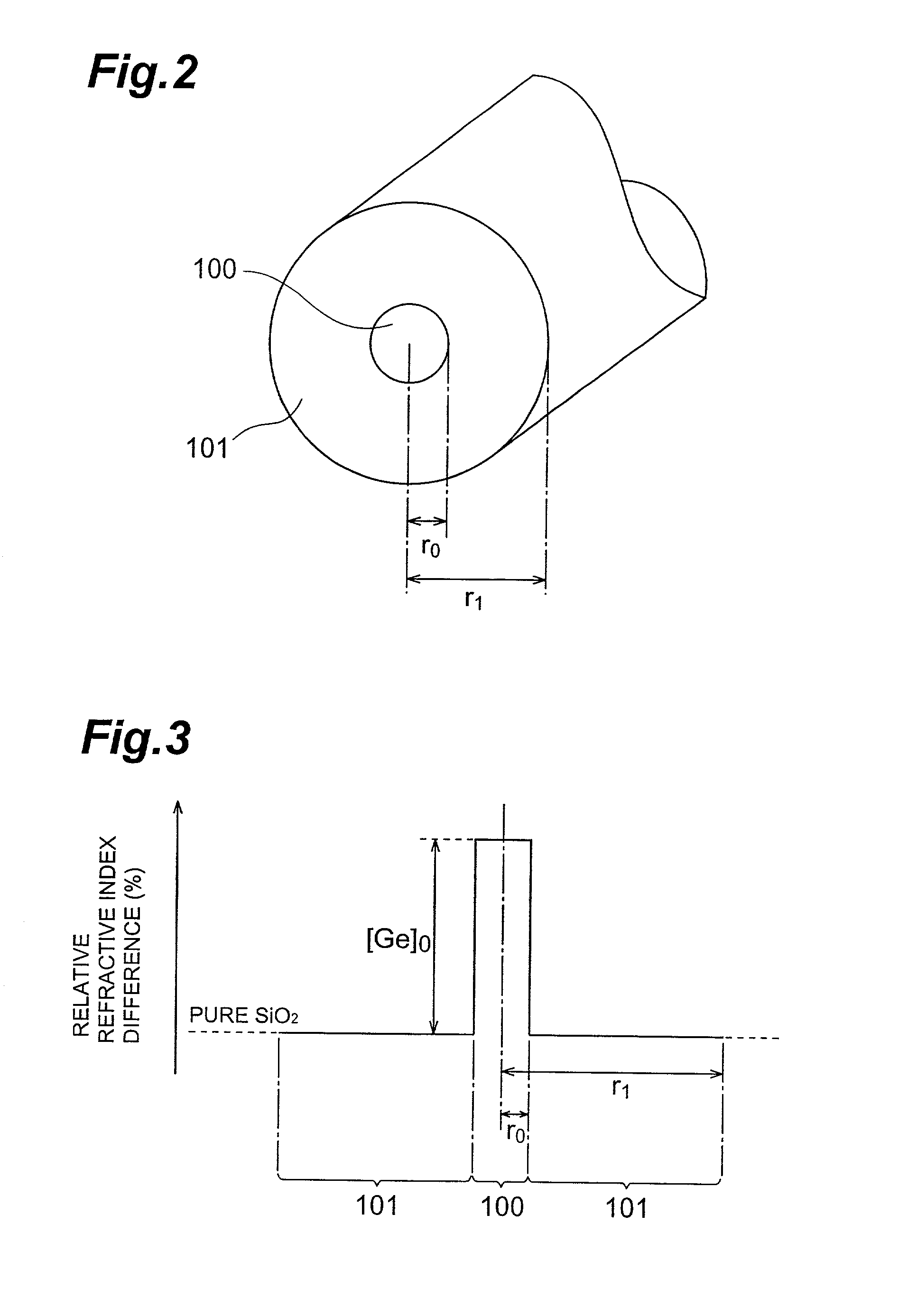

[0126] This optical fiber is an optical fiber of SiO.sub.2 glass (silica glass) type; and comprises a core region 600 including the center axis of the optical fiber, and a cladding region 700 provided at the outer periphery of the core region 600.

[0127] The core region 600 is formed such that the outer periphery thereof has a radius of r.sub.0. In the core region 600, pure SiO.sub.2 glass is doped with a predetermined amount of Cl (chlorine) as an additive for enhancing the refractive index. Consequently, the average relative refractive index difference within the core region 600 is .DELTA.n.sub.0 (where .DELTA.n.sub.0>0).

[0128] On the other hand, the cladding region 700 in this embodiment comprises two layers of cladding, i.e., an inner cladding layer 701 provided at the outer periphery of th...

second embodiment

[0138] FIG. 8 is a chart showing the refractive index profile of the second optical fiber in accordance with the present invention.

[0139] As in the first embodiment, this optical fiber is an optical fiber of SiO.sub.2 glass (silica glass) type; and comprises a core region 600 including the center axis of the optical fiber, and a cladding region 700 provided at the outer periphery of the core region 600.

[0140] The configurations of the core region 600 and cladding region 700 are substantially the same as those of the optical fiber shown in FIG. 7, but differ therefrom in the configuration of the outer cladding layer 702 of the cladding region 700. Namely, in this embodiment, the outer cladding layer 702 is not doped with F (fluorine), whereby it is made of pure SiO.sub.2. Therefore, the average relative refractive index differences of the cladding regions 701 and 702 have a relationship of 0=.DELTA.n.sub.2>.DELTA.n.sub.1.

[0141] The average relative refractive index difference .DELTA....

third embodiment

[0145] FIG. 9 is a chart showing the refractive index profile of the second optical fiber in accordance with the present invention.

[0146] As in the first and second embodiments, this optical fiber is an optical fiber of SiO.sub.2 glass (silica glass) type; and comprises a core region 600 including the center axis of the optical fiber, and a cladding region 700 provided at the outer periphery of the core region 600. Here, the configuration of the core region 600 is substantially the same as that of the core regions 600 of the optical fibers shown in FIGS. 7 and 8.

[0147] On the other hand, the cladding region 700 in this embodiment has a single cladding layer 701. The cladding layer 701 is formed such that the outer periphery thereof has a radius of r.sub.1. In the cladding layer 701, pure SiO.sub.2 glass is doped with a predetermined amount of F (fluorine) as an additive for lowering the refractive index. As a consequence, the average relative refractive index difference in the cladd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com