Contact lens and process for fitting

a technology of contact lenses and fittings, applied in the field of contact lenses, can solve the problems of limited success, blue vision at near points, and the ability of the eye's natural lens, and achieve the effect of increasing the near power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

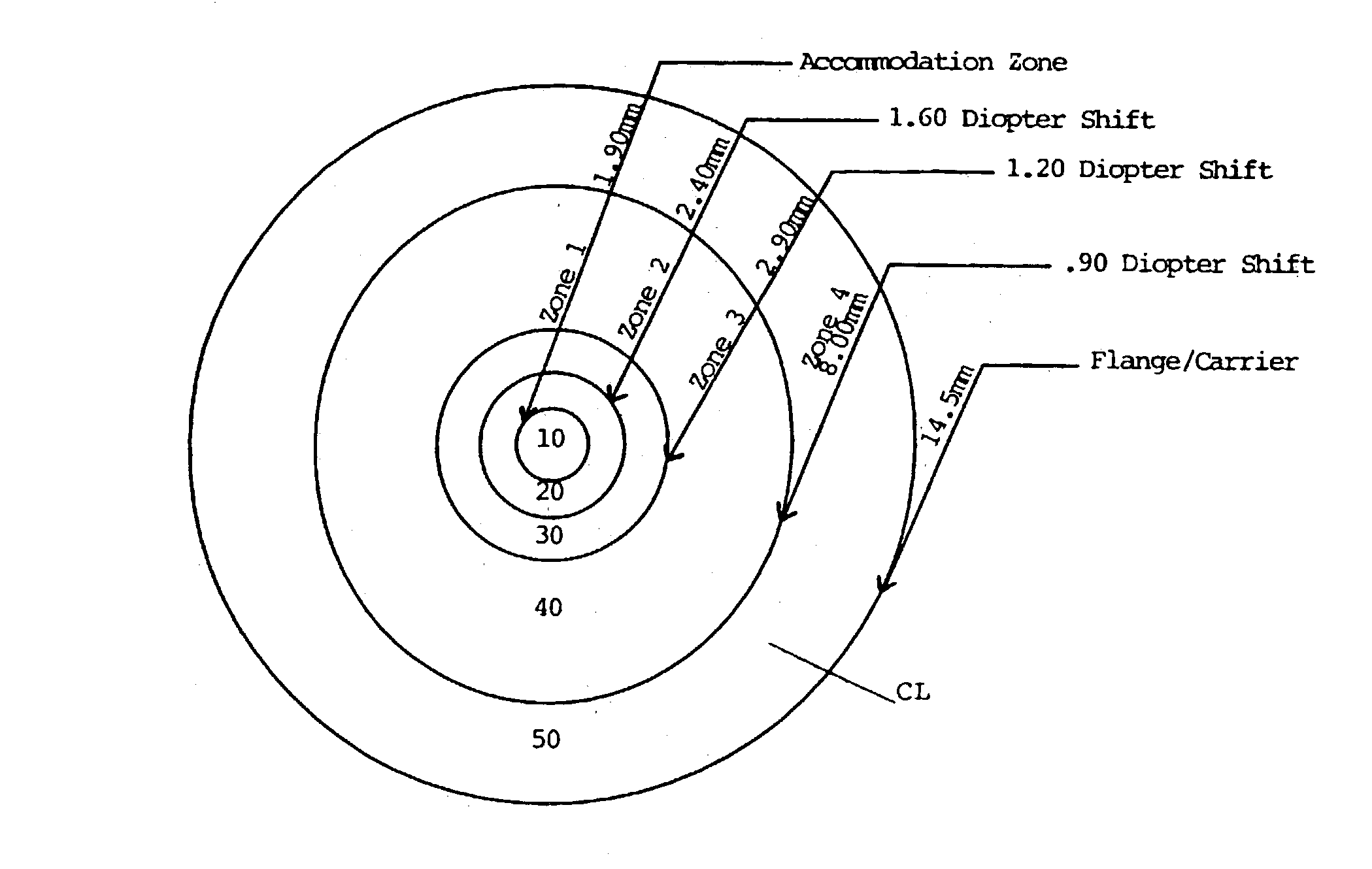

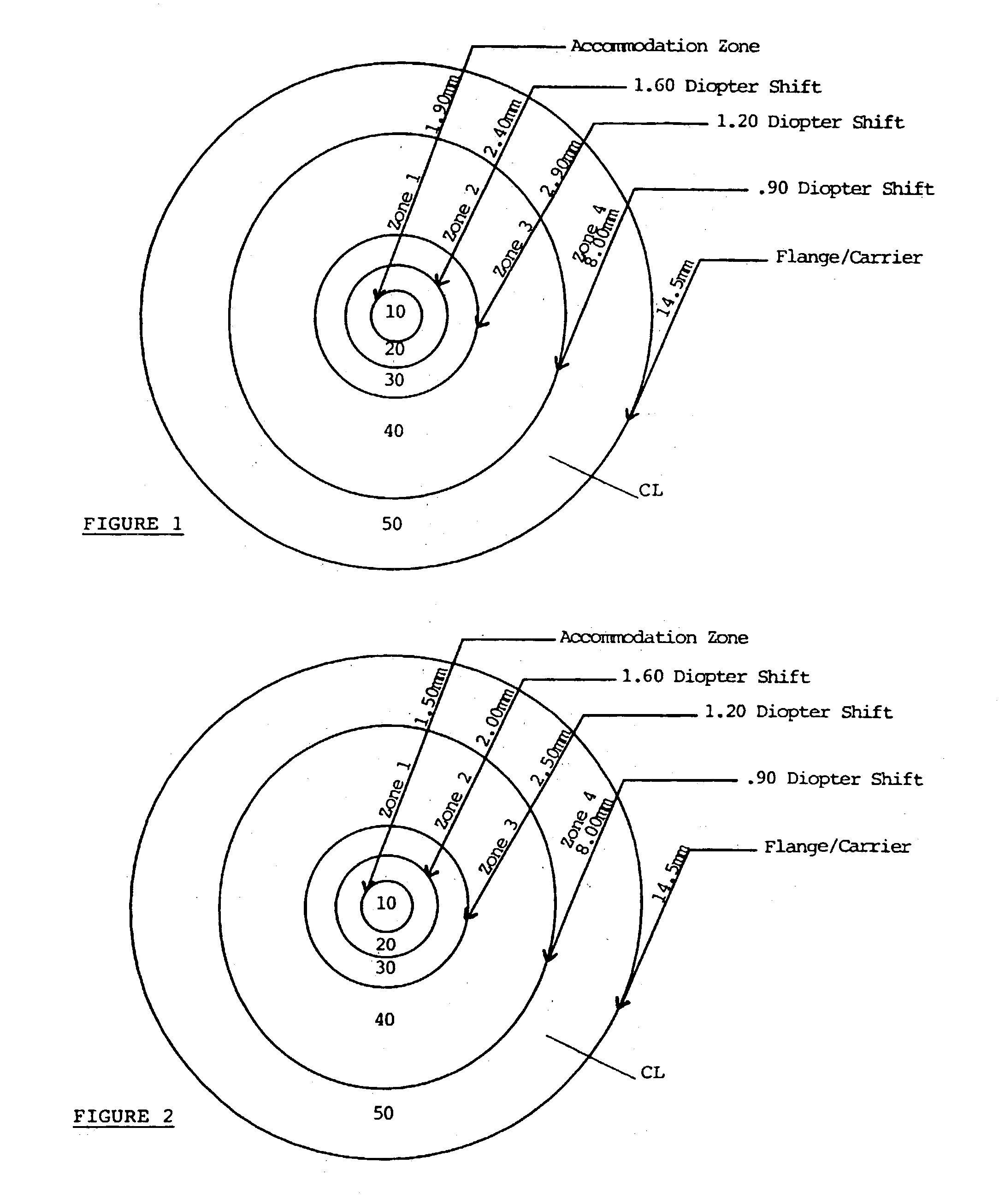

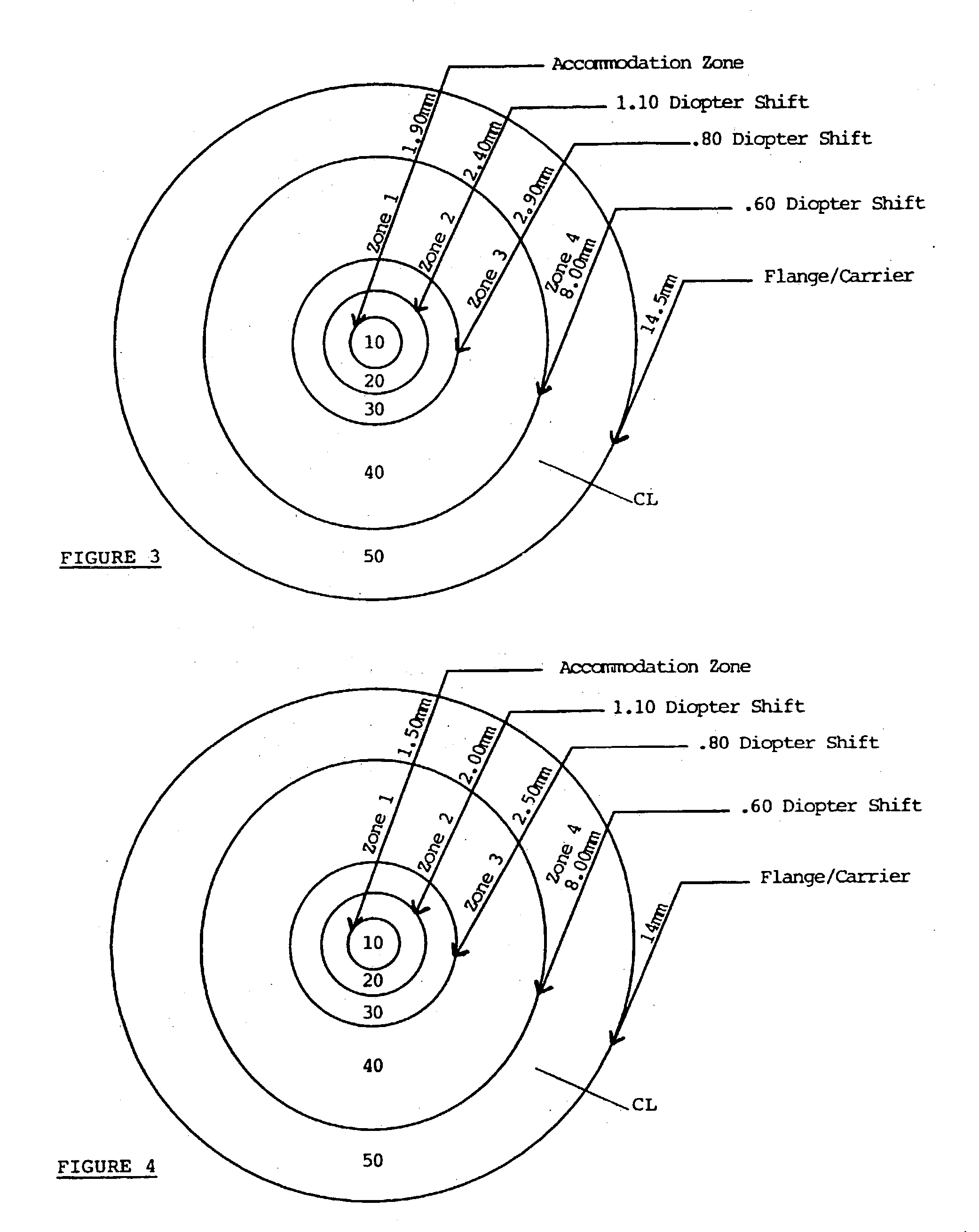

[0065] A Microturn 9000 three axis radius lathe with aspheric surface cutting capabilities has been used to make contact lenses according to the present invention with base curves of 8.6 millimeters wet (6.6 millimeters dry). The lenses were manufactured dry from Ocufilcon B (a 53% water content material) and were hydrated afterwards. Therefore compensating calculations were made to achieve the appropriate hydrated parameters, such as base curve, radial expansion, linear expansion, power changes due to changes in index of refraction caused by hydration. When hydrating Ocufilcon B, the linear expansion parameter is approximately 1.35, the radial expansion parameter is approximately 1.30, and the power change parameter is approximately 0.57. The settings for the various radii of curvature in the various zones (for dry manufacturing using Ocufilcon B) are shown in the following cutting charts:

1 Zone 1 2 3 4 CENTER 1.10 1.50 1.90 6.00 DIA. C.T. DIST. POWER 1.40 1.80 2.20 6.00 DIA. C.T. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com