Optical information recording medium

a technology of optical information and recording medium, which is applied in the field of optical information recording medium, can solve the problems of dyes having a drawback, dyes cannot have good recording/reproducing characteristics, and complex index of refraction has a large wavelength dependency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0173] The following components were dissolved in 2,2,3,3-tetrafluoropropa-nol to prepare a dye solution (i.e., a recording layer coating liquid).

[0174] Dye Compound (.alpha.)

[0175] Formazan Ni Chelate Compound (1)

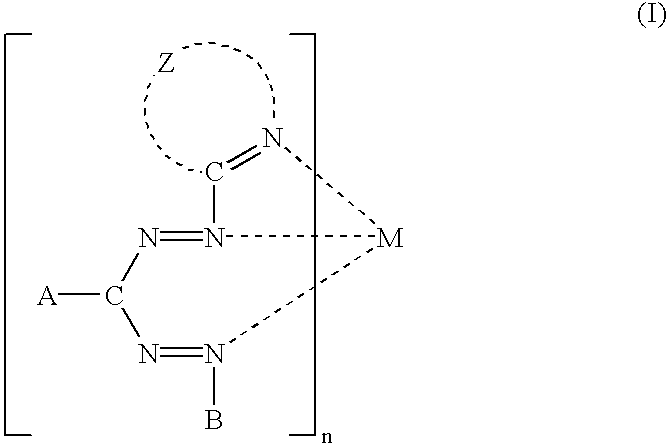

[0176] having formula (I) 49 moles 7

[0177] (Z: 3,6-phenoxytriazole, A: 2-trifluoromethylphenyl, B: phenyl, M: Ni, n=2)

[0178] Trimethinecyanine Dye (2)

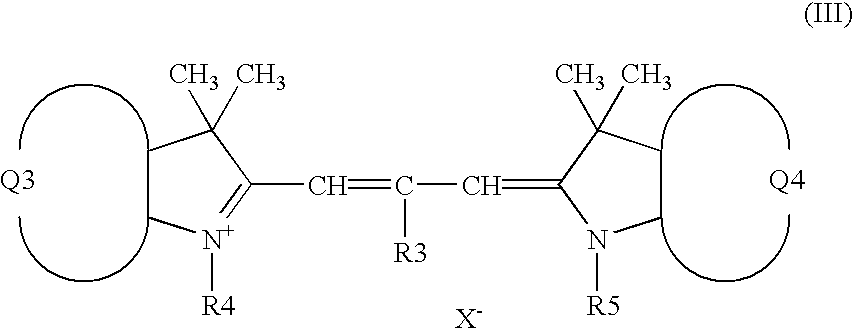

[0179] having fromula (III) 49 moles 8

[0180] (Q3 and Q4: a group forming a benzoindolenine ring together with a pyrrole ring, R3: --H, R4 and R5: --CH.sub.3, X.sup.-: --ClO.sub.4.sup.-)

[0181] Dye Compound (.beta.)

[0182] Pentamethinecyanine Compound (11)

[0183] having formula (VI) 2 moles 9

[0184] (Q3 and Q4: a group forming a benzoindolenine ring together with a pyrrole ring, R3: --H, R4 and R5: --CH.sub.3, X.sup.-: --ClO.sub.4.sup.-)

[0185] The recording layer coating liquid was coated by a spin coating on a polycarbonate disc having a diameter of 120 mm and a thickness of 0.6 mm, on which a guide groove having a depth of about...

example 2

[0197] The procedures for preparation and evaluation of the recording medium in Example 1 were repeated except that the dye compounds (.alpha.) and (.beta.) were replaced with the following dyes, respectively, and the solvent was replaced with a mixture solvent of tetrahydrofuran, 2-ethoxyethanol and ethylcyclohexanone.

[0198] Dye Compound (.alpha.)

[0199] Tetraazaporphyradine Compound (3)

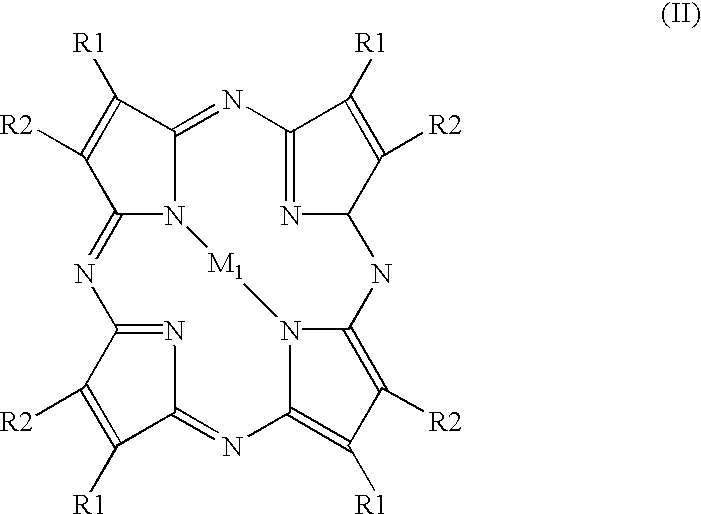

[0200] having formula (II) 90 moles 10

[0201] (M1: Cu, R1: --O--C(CF.sub.3).sub.2--C.sub.5H.sub.6, R2: --H)

[0202] Dye Compound (.beta.)

[0203] Phthalocyanine Compound (12)

[0204] having formula (V) 10 moles 11

[0205] (M2: VO; A1, A3, A5, A7: --O--O--C(CF.sub.3).sub.2--C.sub.5H.sub.6-;

[0206] A2, A4, A6, A8: --H)

[0207] Thus, an optical information recording medium was prepared.

[0208] The evaluation results are shown in Table 2. As can be understood from Table 2, the recording medium of Example 2 has good recording sensitivity.

example 3

[0209] The procedures for preparation and evaluation of the recording medium in Example 1 were repeated except that the Pentamethinecyanine compound (11) was replaced with a dye compound (13) having formula (V), and the molar ratio of the compounds (1), (2) and (13) was changed to 46:46:8. 12

[0210] (M2: Si(OCOC.sub.4H.sub.9).sub.2; A1, A3, A5, A7: --O--CH.sub.2--CF.sub.2--CF.sub.2--CF.sub.3; A2, A4, A6, A8: --H)

[0211] The evaluation results are shown in Table 2. As can be understood from Table 2, the recording medium of Example 3 has good recording sensitivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength range | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| thermal decomposition temperatures Tα | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com