Metallization of carbon nanotubes for field emission applications

a carbon nanotube and field emission technology, applied in the manufacture of electric discharge tubes/lamps, electrode systems, liquid/solution decomposition chemical coatings, etc., can solve the problems of difficult to achieve uniformity, limited substrates that can be used, and poor field emission quality of mwnts compared to single-wall carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Coating Single-Wall Carbon Nanotubes with a Cobalt Thin Film

[0031] This process provides a way of depositing a metal thin film or coating on the surface of carbon nanotubes using an electroless plating technique. Using this relatively inexpensive and simple process, metallized carbon nanotubes can be made efficiently in relatively large amounts.

[0032] The single-wall carbon nanotube (SWNT) material used here was purchased from Iljin Nanotech, Inc. (Korea). The length of the SWNTs ranged from approximately several micrometers to approximately 20 micrometers, and the diameters were generally less than about 2 nanometers.

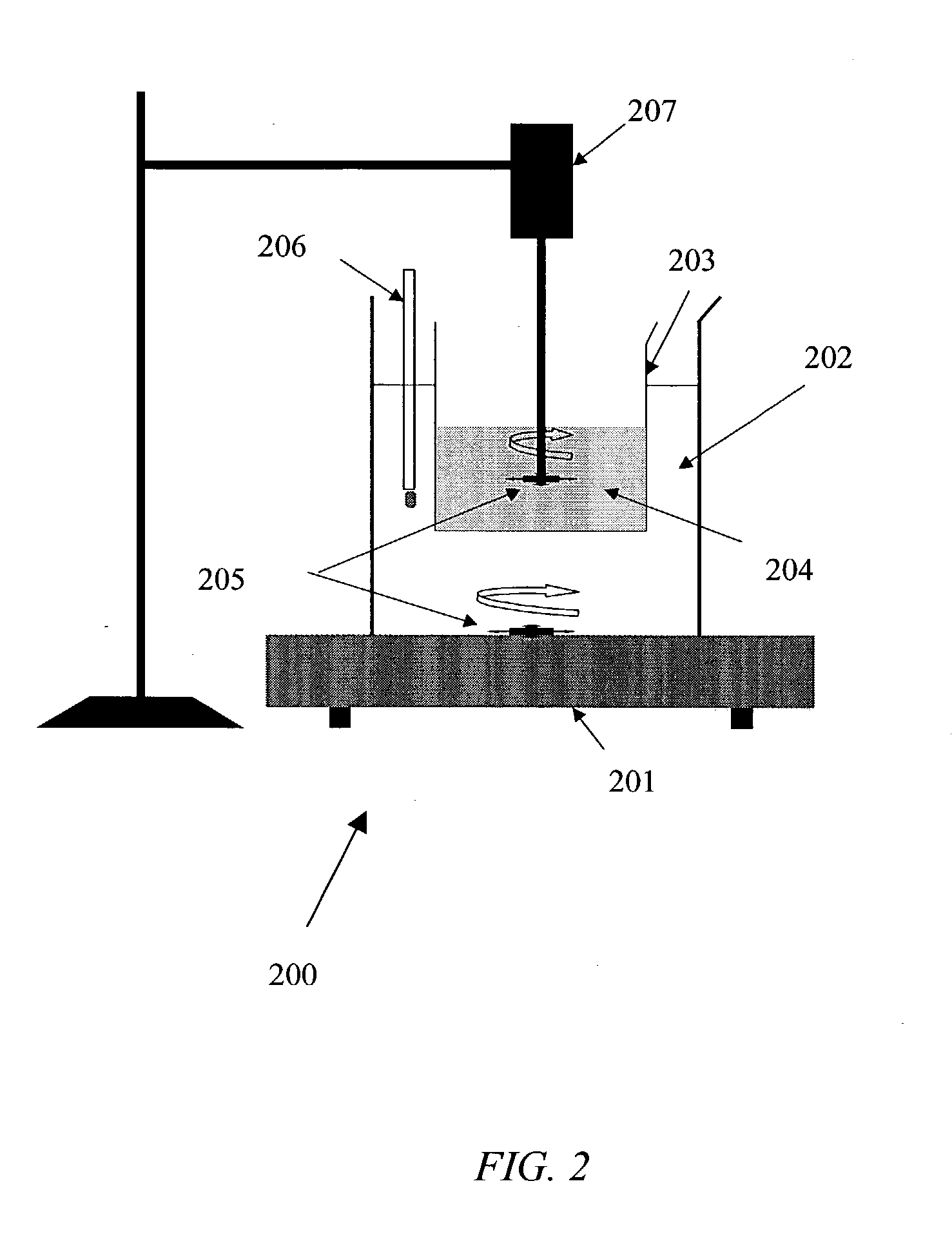

[0033] Referring to FIG. 2, electroless plating apparatus 200 comprises an electroless plating solution 204 contained in a beaker 203 which in turn is immersed in a water bath 202. Water bath 202 is heated by a magnetic stirring hotplate 201 and temperature is monitored by thermometer 206. Stirring is accomplished with stir bars 205 activated by the magnetic sti...

example 2

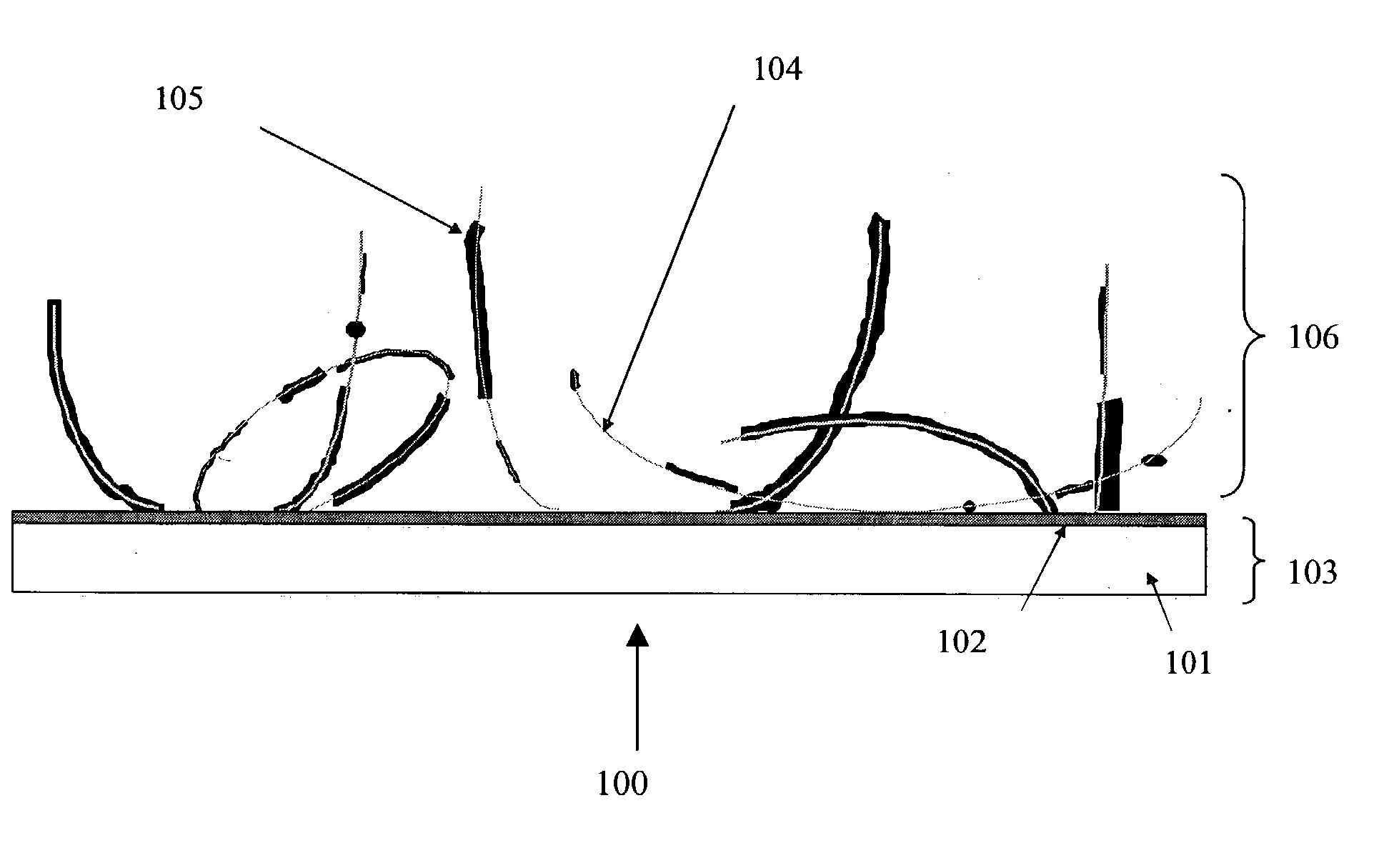

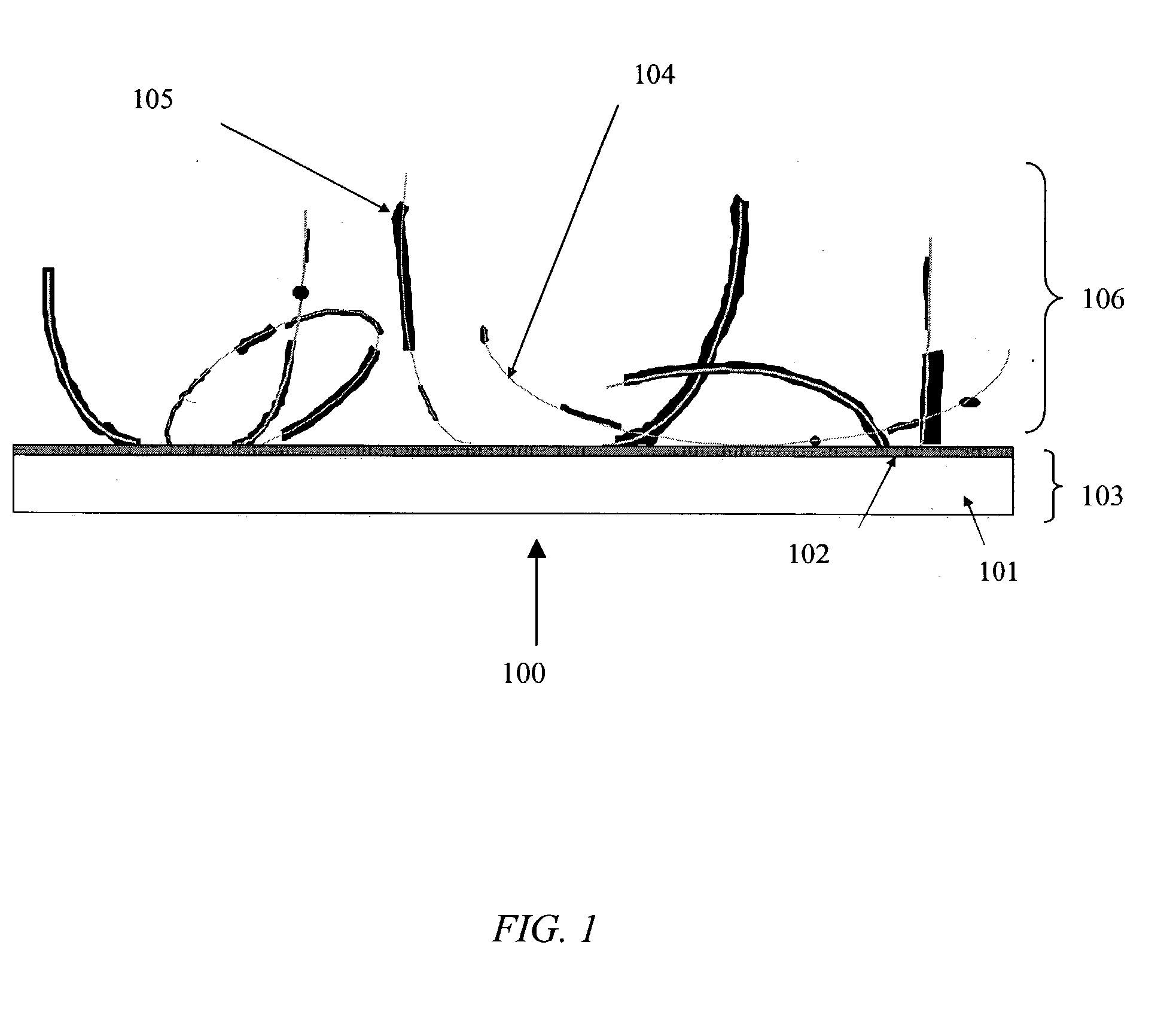

[0043] Dispensing Carbon Nanotubes onto a Substrate

[0044] In this example, cobalt-metallized SWNT powder was mixed with isopropyl alcohol (IPA) to form a suspension. The suspension comprised approximately 1 gram of metallized SWNTs in 1000 ml IPA. Because the SWNTs clump together readily, ultrasonic agitation was used to disperse the nanotubes in the IPA before spraying the solution onto cathode substrates. The SWNT / IPA suspension was sprayed onto conductive indium-tin-oxide (ITO) / glass substrate with an area of 2.times.2 cm.sup.2. In order to prevent the IPA from flowing uncontrollably, the substrate was heated up to approximately 30-70.degree. C. on both the front side and back side during the spraying process. The substrate was sprayed back and forth several to tens of times until the carbon nanotubes covered on the entire surface. The thickness of the carbon nanotube layer was about 1-20 .mu.m. The film was then dried in air.

[0045] FIGS. 3 and 4 show optical images of CNT materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com