Modified container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023] This Example illustrates the invention.

[0024] A 34 g PET beer bottle having 1% of an oxygen scavenger dispersed in the walls was provided with an epoxy-amine coating. An improvement in oxygen barrier rate when compared to the absence of the epoxy-amine coating was determined to be 3.8 times.

example 2

[0025] This Example illustrates the significant effect of an oxygen scavenger in conjunction with an external barrier layer.

[0026] Polyethylene-terephthalate (PET) bottles were blown from a blend of commercial PET and 1 wt % Amosorb (OFC grade) with 473 ml capacity. Amosorb is a proprietary oxygen scavenging copolymer material supplied by BP chemicals. The copolymer is a copolymer of PET having polybutadiene oligomer segments and is produced as described in the aforementioned U.S. Pat. No. 6,083,585. The bottles were spray coated on the outside of the bottles with a contiguous outer film of an epoxy-amine resin supplied by PPG Industries under the trademark "BAIROCADE" and produced as described in the aforementioned U.S. Pat. No. 5,637,365. The thickness of the layer was about 0.4 mil.

[0027] Control bottles were also prepared in which there was only no modification to the bottle walls, in which only 1% Amosorb was present and in which only the epoxy-amine resin coating was present.

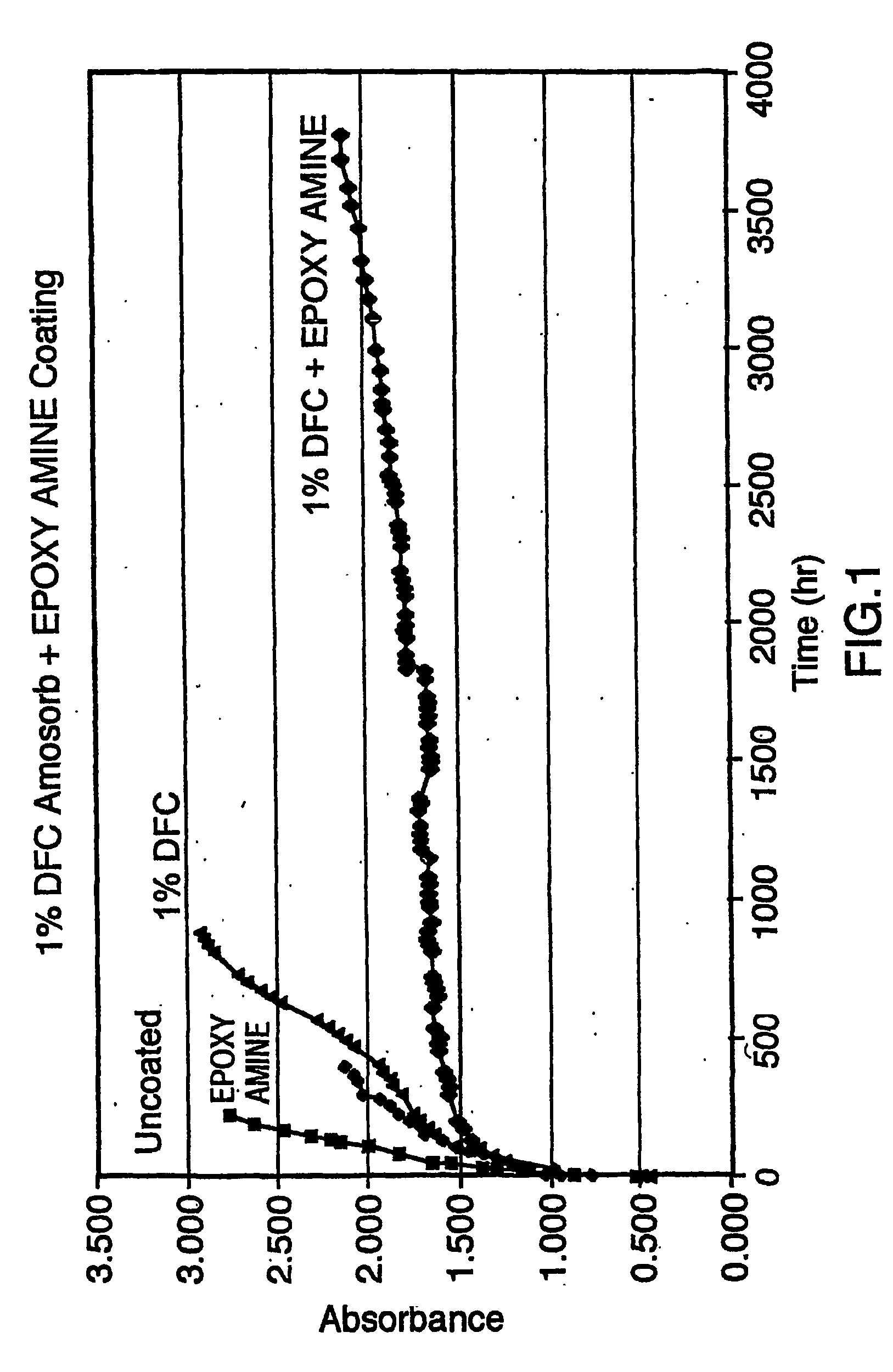

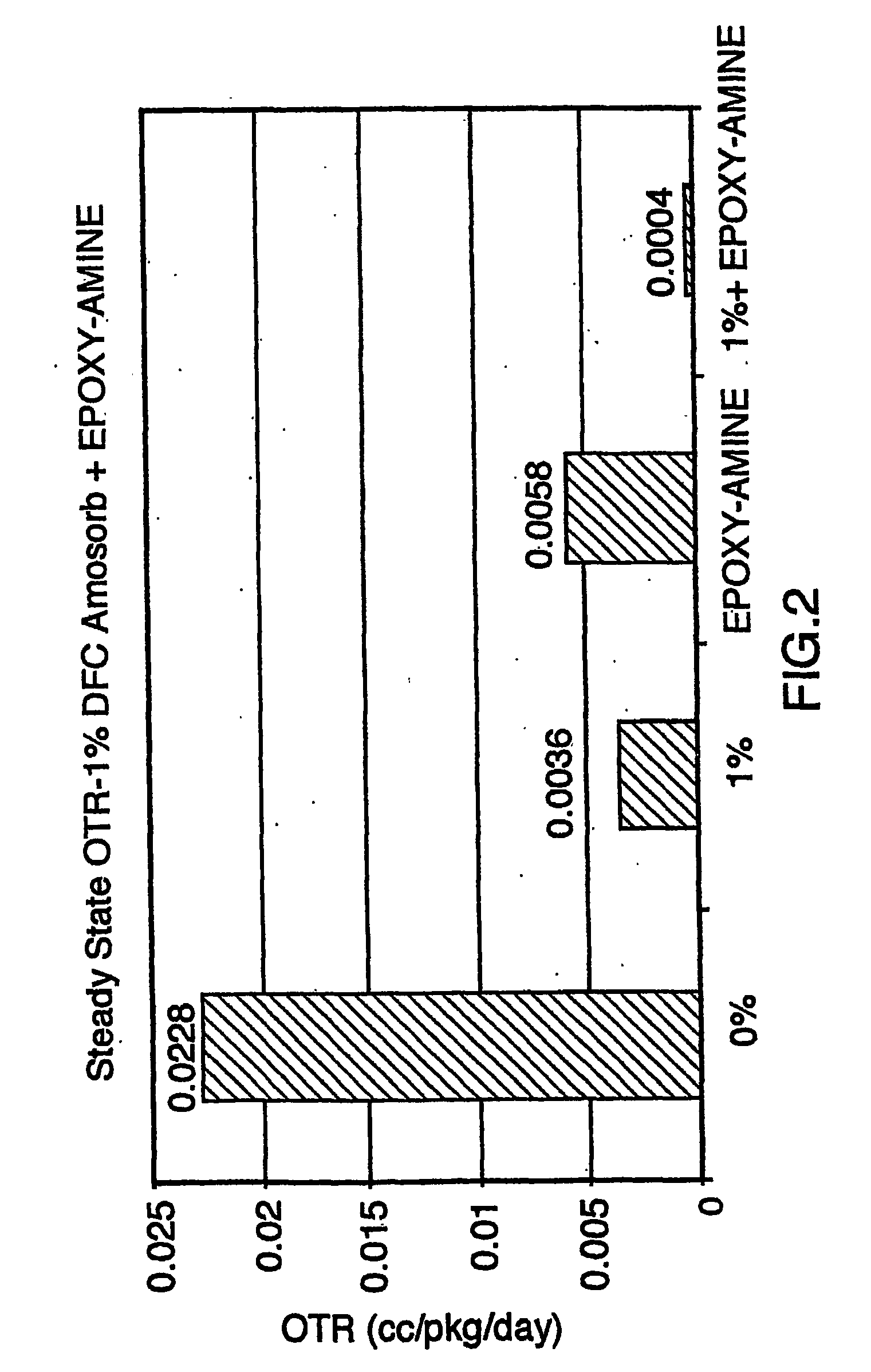

[...

example 3

[0030] This Example illustrates the synergistic effect of an oxygen scavenger material in conjunction with an external barrier layer.

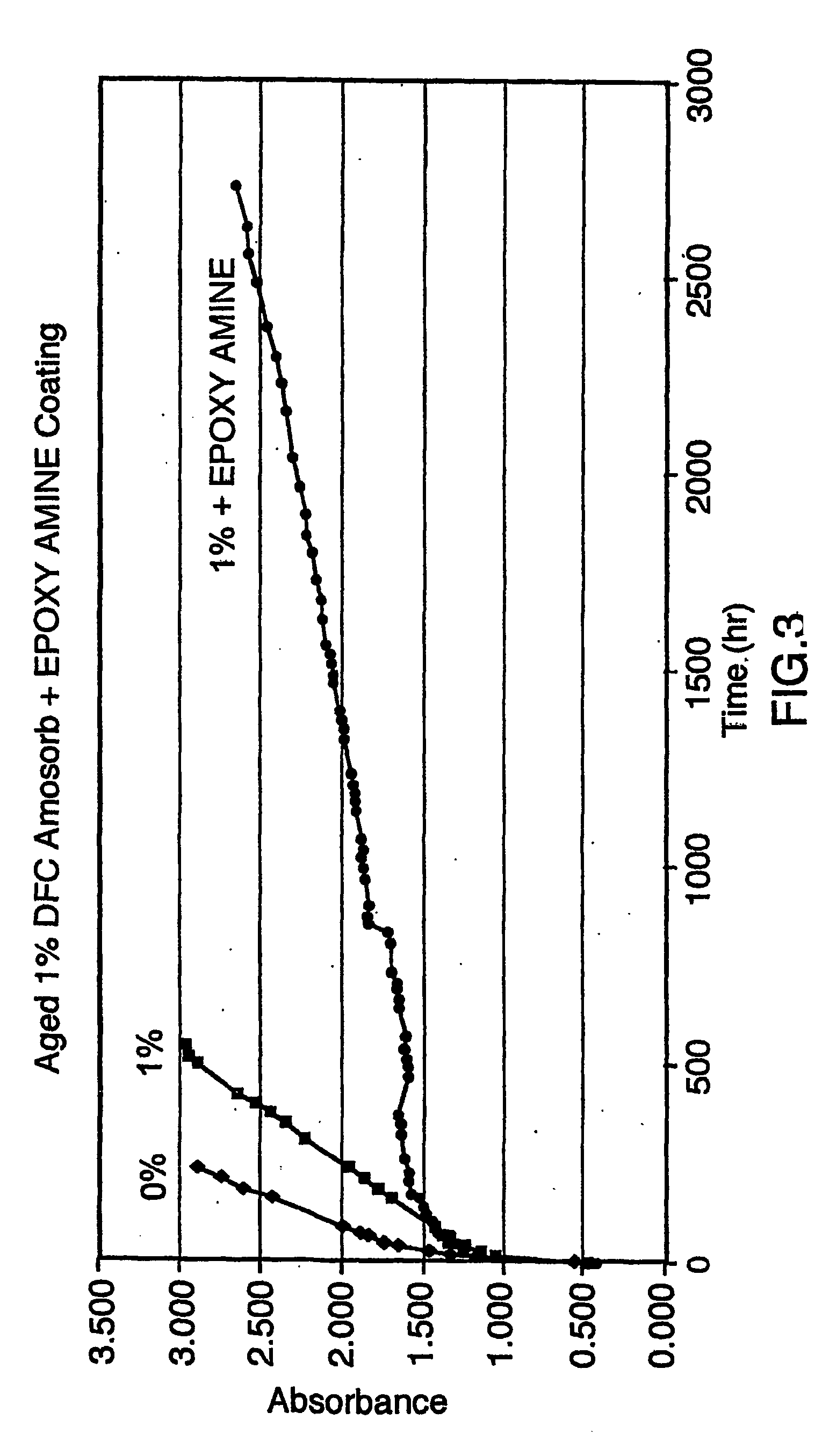

[0031] The procedure of Example 2 was repeated except that a comparison was made between bottles which were filled immediately after the bottles were made and these which were filled after 5 weeks standing empty ("aged").

[0032] The results obtained for oxygen absorbance of the aged bottles were plotted graphically and appear in FIG. 3. These results show the same kind of results as FIG. 1 for the unaged bottles. The oxygen transmission rate (OTR) for the aged and unaged ("Time 0") bottles were plotted graphically and appear in FIG. 4. These results show that, while the 1% Amosorb containing bottles exhibited a greater OTR in the aged bottles, showing some loss of effectiveness of the Amosorb material, the external epoxy-amine coating significantly reduced the OTR by an order of magnitude.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com