Waterpump

a water pump and water pump technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of reducing the pump efficiency compared with supplied electricity, reducing the efficiency of the pump, and reducing the quantity of coolant supplied and the pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are now described below with reference to the accompanying drawings. However, the invention is not limited to the embodiments disclosed herein. All modifications within the appended claims and equivalents relative thereto are intended to be encompassed in the scope of the claims.

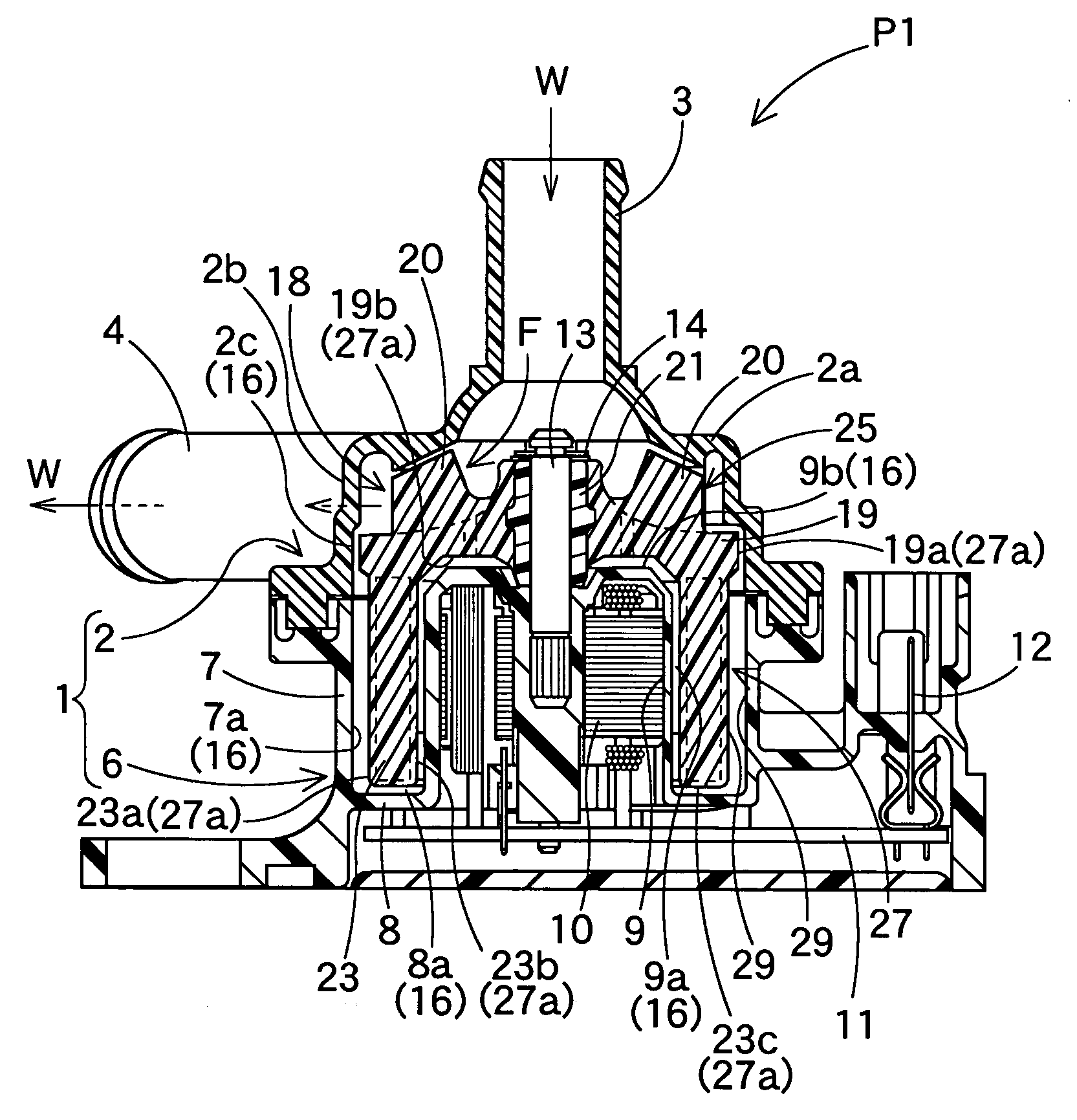

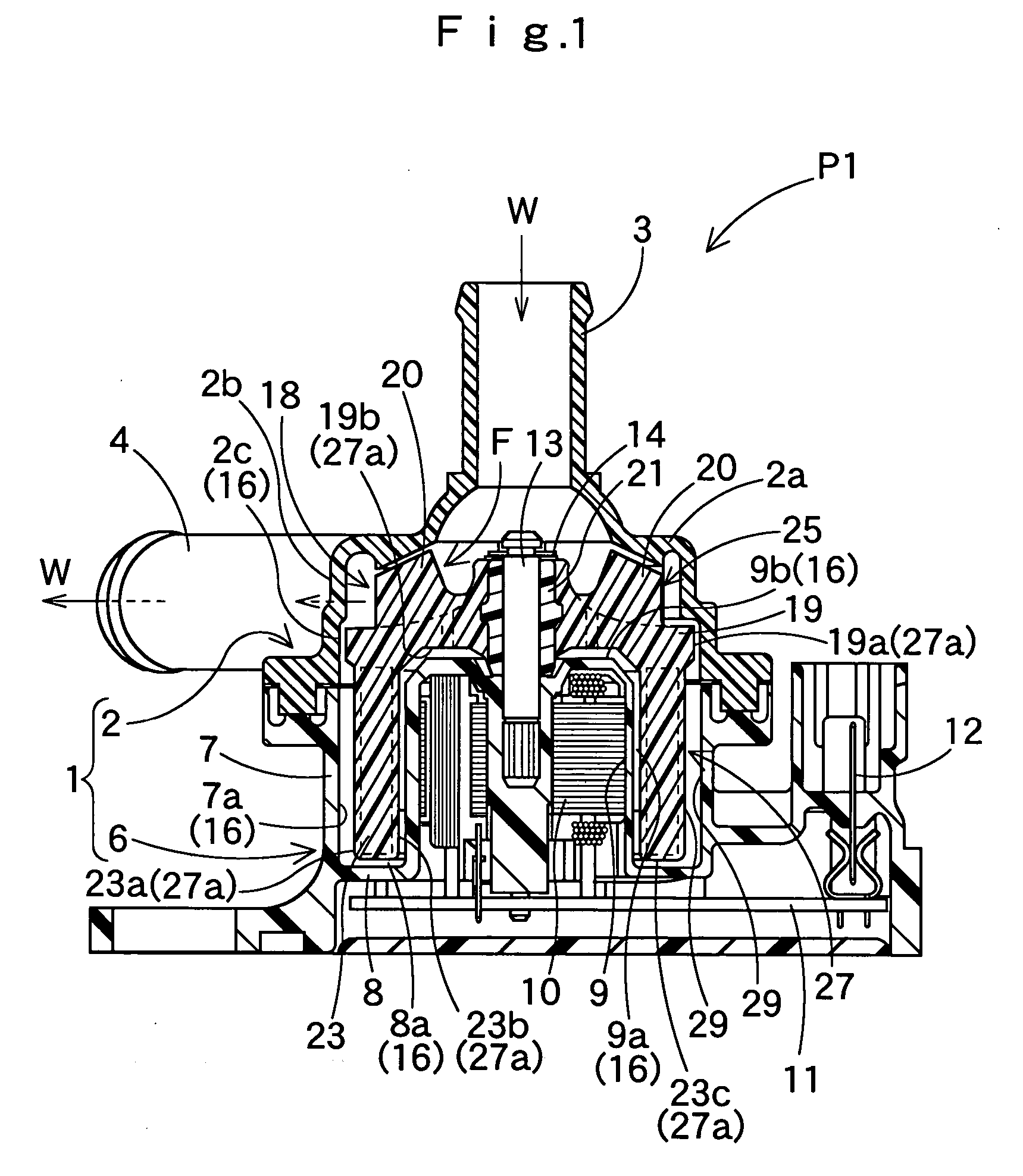

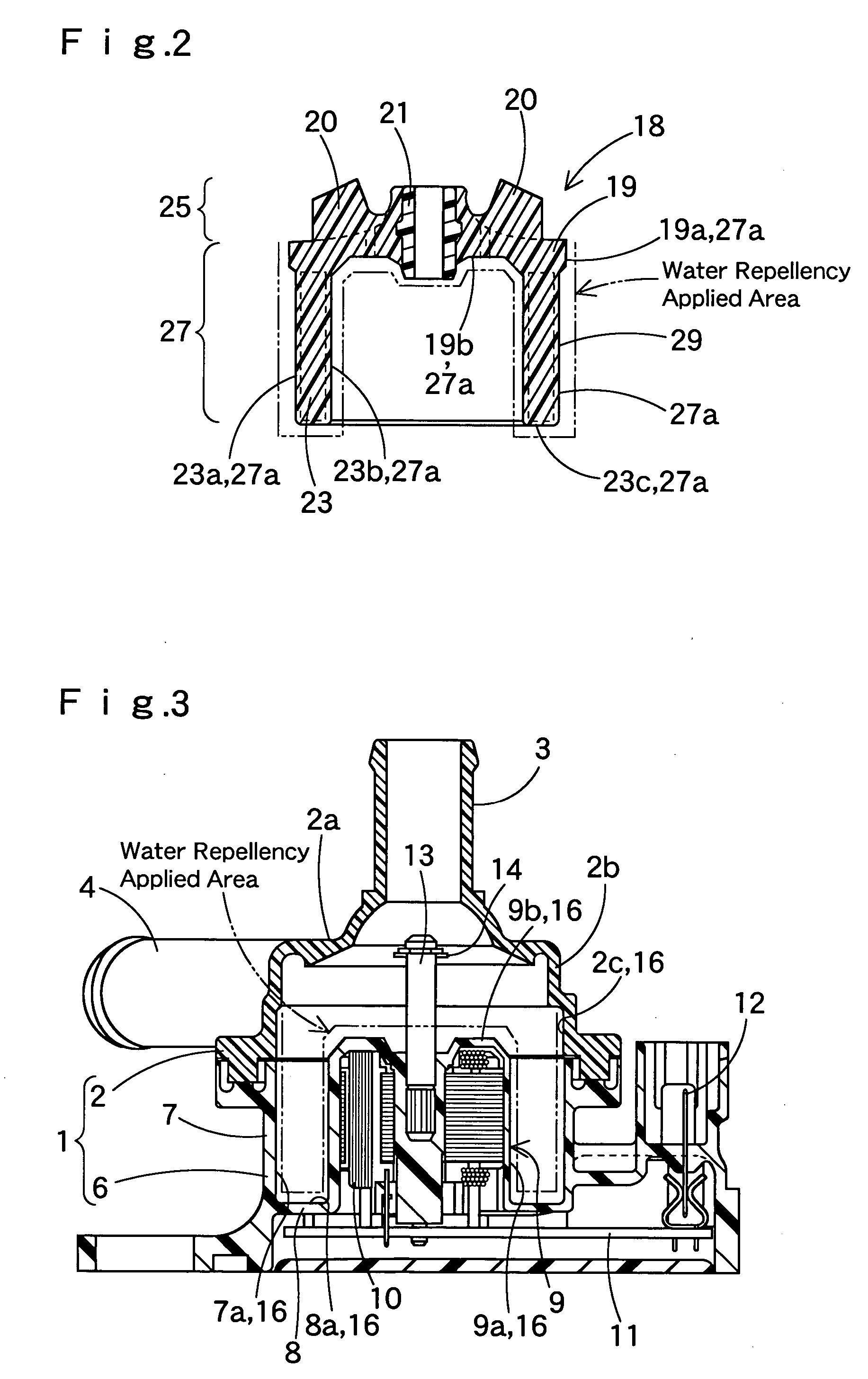

[0024] FIGS. 1 to 3 illustrate a first embodiment P1 of the waterpump according to the present invention. The waterpump P1 is a magnetic coupling pump for pumping engine coolant W for vehicles. The pump P1 includes a housing 1 which is made from synthetic resin and has therein a rotor 18 with a plurality of impellers 20 for feeding the coolant W.

[0025] The housing 1 includes a pump chamber 2 in which the impellers 20 of the rotor 18 are located, and a motor chamber 6 located below the pump chamber 2. The pump chamber 2 has a ceiling wall 2a and has a substantially cylindrical shape as a whole. An inlet pipe 3 for introducing the coolant W is projected upw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear stress | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com