Image capturing device

a technology of image capture and capturing device, which is applied in the direction of exposure control, optical radiation measurement, instruments, etc., can solve the problems of insufficient luminance, inability to obtain luminance as necessary for flash use, and increase in power consumption pd by more than a factor of 2.5, so as to eliminate waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0037] First Embodiment

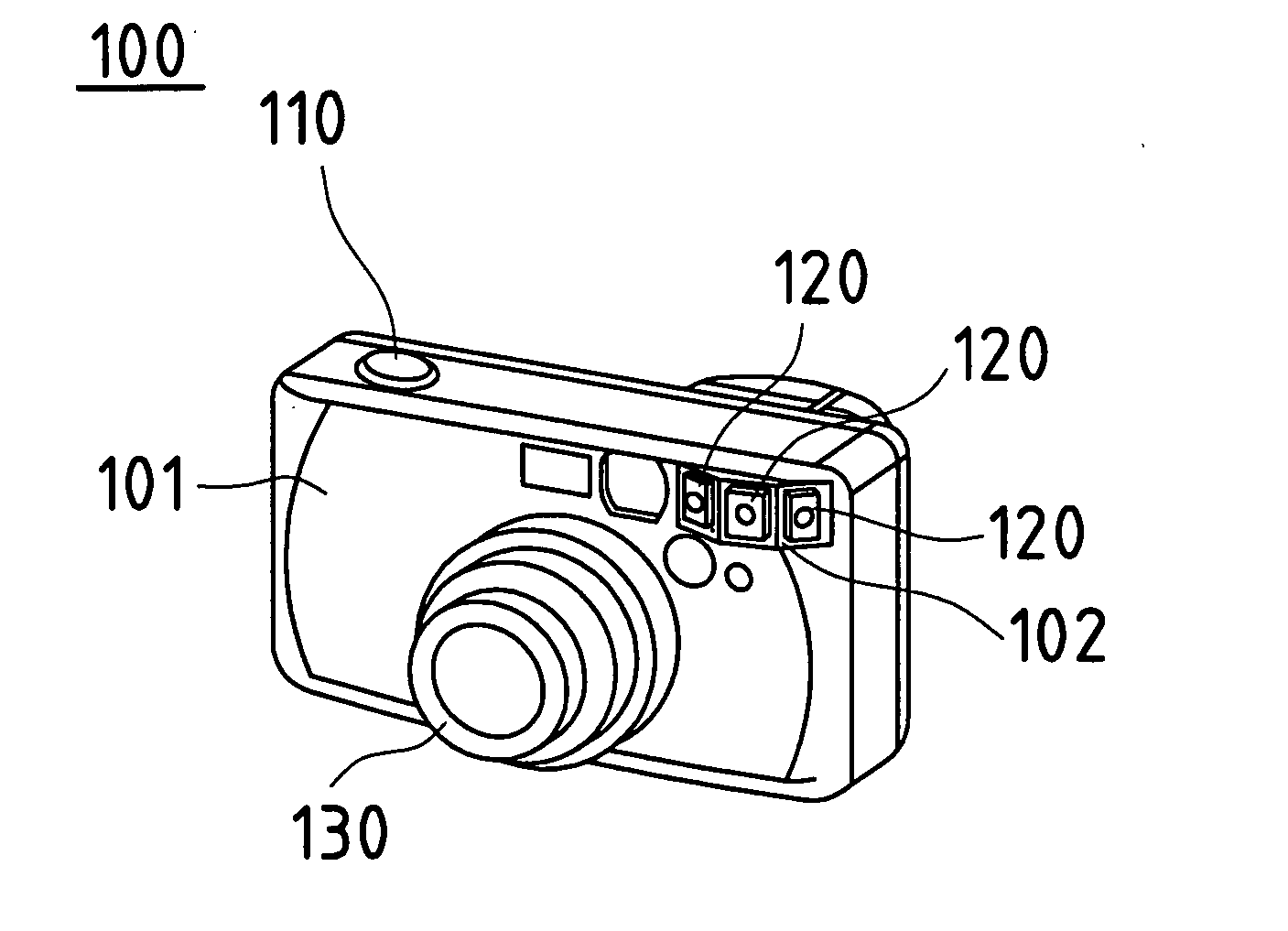

[0038]FIG. 1 is a drawing showing the external appearance of a camera associated with a first embodiment of the image capturing device of the present invention. Note that this camera is assumed to use silver halide film.

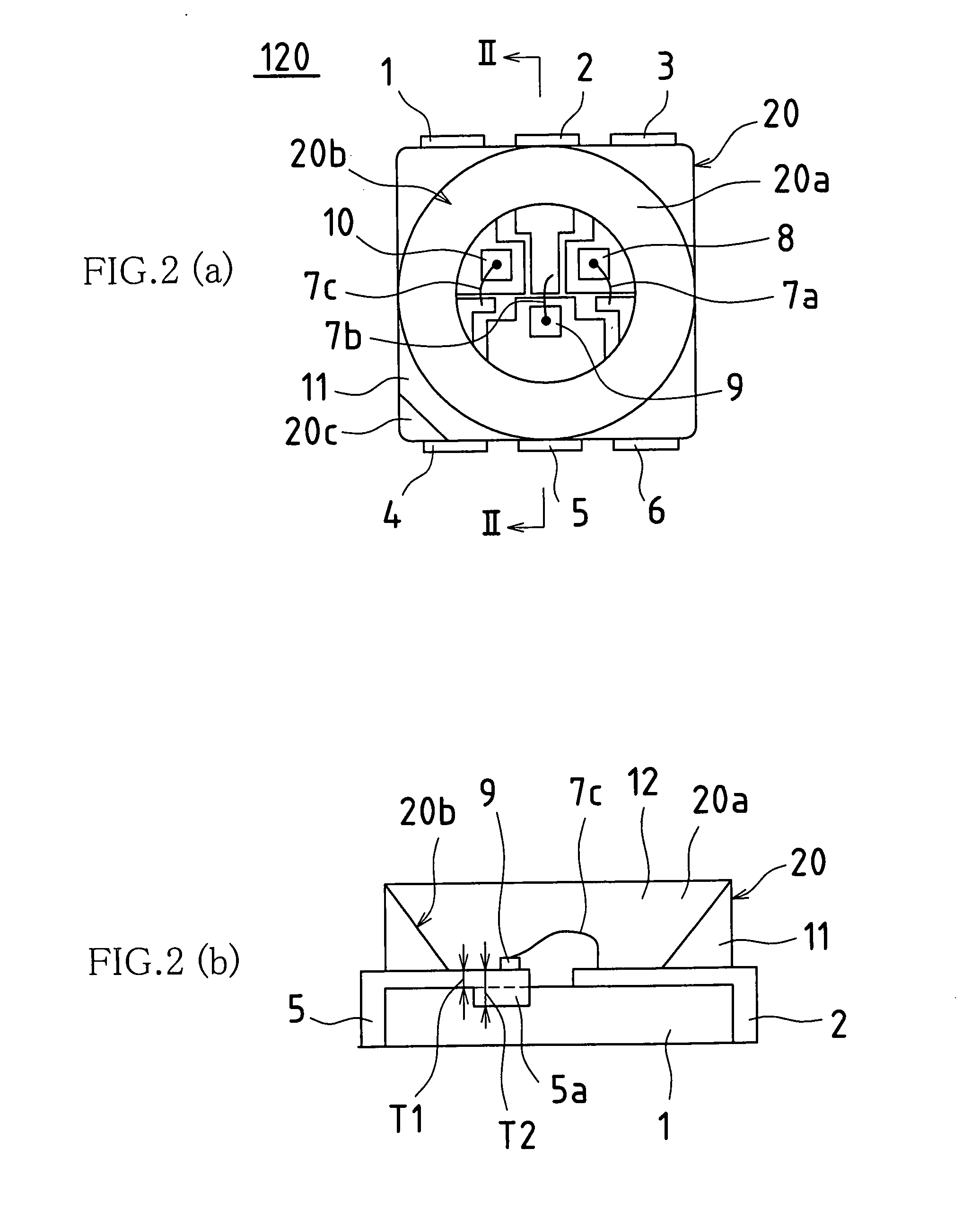

[0039] As shown in FIG. 1, photographic lens 130 equipped with multibarrel lens barrel is arranged toward the bottom in roughly the central region of the front of body 101 of squat box-shaped camera 100. This photographic lens 130 can be extended and / or retracted as a result of actuation by actuating member(s), not shown; extension and / or retraction of photographic lens 130 permitting change in photographic magnification. Three LED devices 120 for flash use are arranged at protruding region 102 formed in the upper right region at the front of camera body 101. These LED devices 120 for flash use are arranged so as to permit light to respectively be irradiated centrally within the field angle of photographic lens 130 as well as to the left and r...

second embodiment

[0076] Second Embodiment

[0077]FIG. 7(a) indicates when a shutter might be open and when it might be closed in an example of a drive signal timing chart for LEDs for flash use in a camera associated with a second embodiment of the image capturing device of the present invention; and FIG. 7(b) shows the corresponding LED drive signals. Note that because, except for the features mentioned below, the second embodiment is identical to the first embodiment which was described with reference to FIGS. 1 through 6, only those aspects that are different therefrom will be described here.

[0078] Internal to this camera is / are monitoring light-receiving element(s) capable of measuring amount(s) of light impinging on image capturing element(s) after passing through photographic lens(es). In the event that LED element(s) is / are used as flash apparatus(es), it is possible, unlike the situation with conventional xenon discharge tubes, to cause light to be emitted in repeated fashion. In the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com