Dispensing unit for ice or snow-like particles

a technology of dispensing unit and ice, which is applied in the direction of lighting and heating apparatus, instruments, domestic cooling apparatus, etc., can solve the problem that the cost of producing the product may be the same gross cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

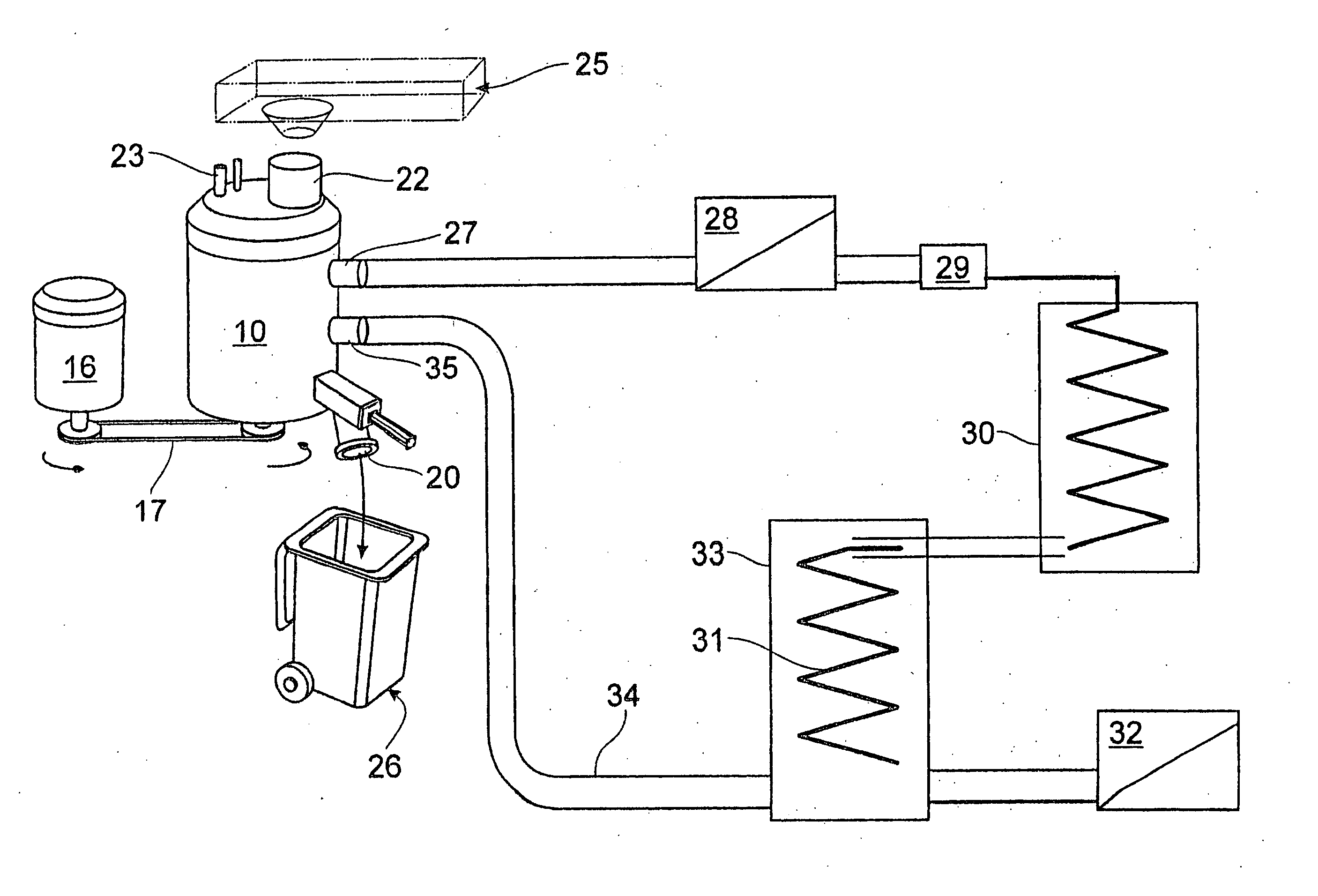

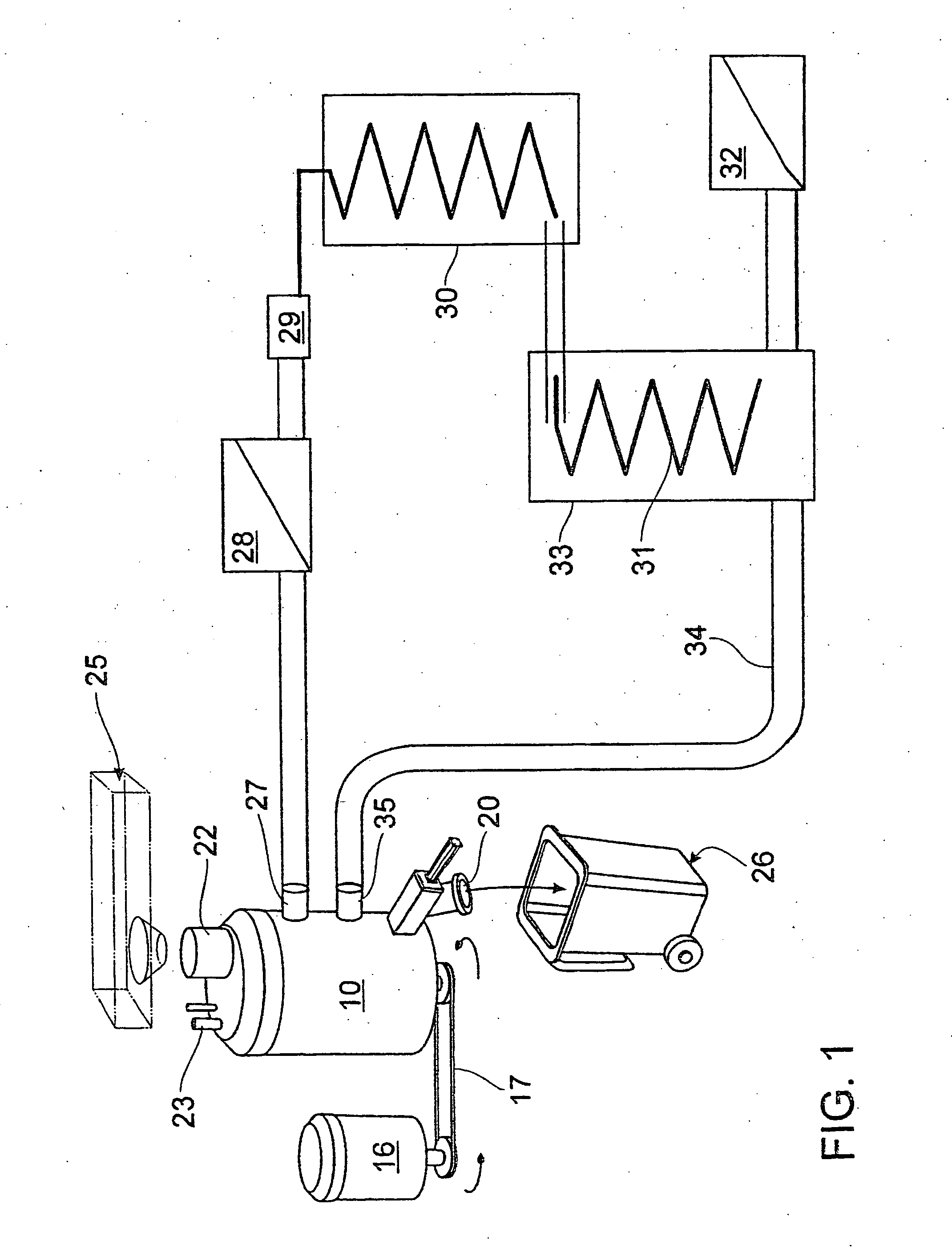

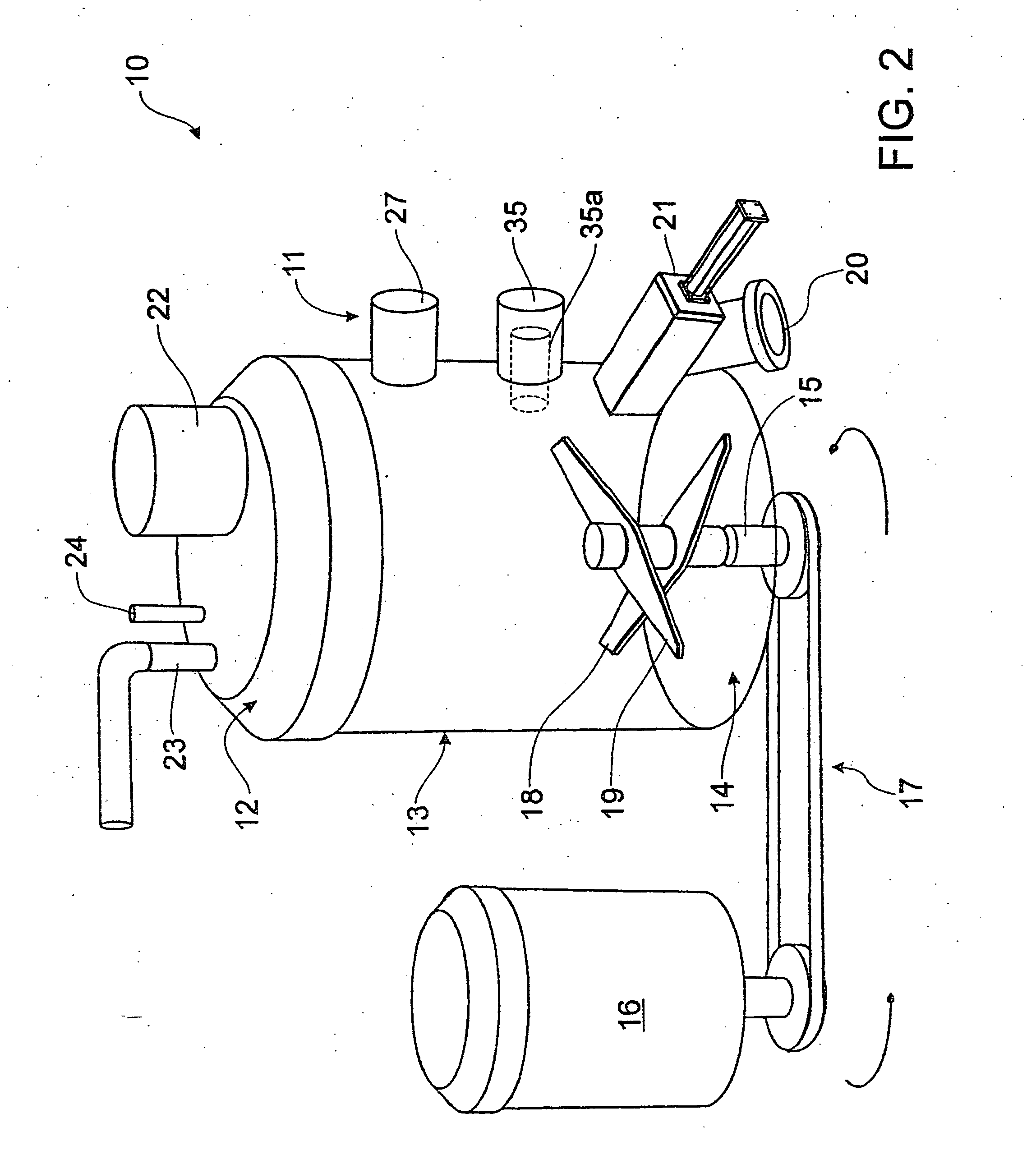

Referring to FIGS. 1 and 2, the mixing vessel 10 has a cylindrical tank-like body 11 with a top wall (or lid) 12, side wall 13 and floor 14 formed of metal and / or plastics material. (The walls may be of metal skin / insulating core / metal skin construction.)

A shaft 15 is rotatably journalled in the bottom wall 14, substantially c-axial with the vertical axis of the vessel 10. The shaft 15 is driven via an electric motor 16 via a drive system 17 (eg., mechanical transmission / pulleys and belt / sprockets and chain).

Respective first and second blades 18,19 are mounted on the shaft 15 at spaced locations and extend substantially radially to the shaft 15. As per the second embodiment shown in FIG. 3, the blades 18,19 are inclined to the axis of the shaft15 in opposite directions so that rotation of the shaft 15 will cause the lower blade 18 to “lift” the mixture in the vessel 10 and the upper blade 19 to “push down” the mixture in opposition thereto for complete mixing of the mixture.

A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com