Vacuum roll coated security thin film interference products with overt and/or covert patterned layers

a technology of overt and/or covert patterned layers and protective coatings, which is applied in the direction of non-fibrous pulp addition, instruments, transportation and packaging, etc., can solve the problems of inability to easily see the features of threads by eye by the average person, and the laser etching takes too long to be cost effective, etc., to achieve the effect of convenient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

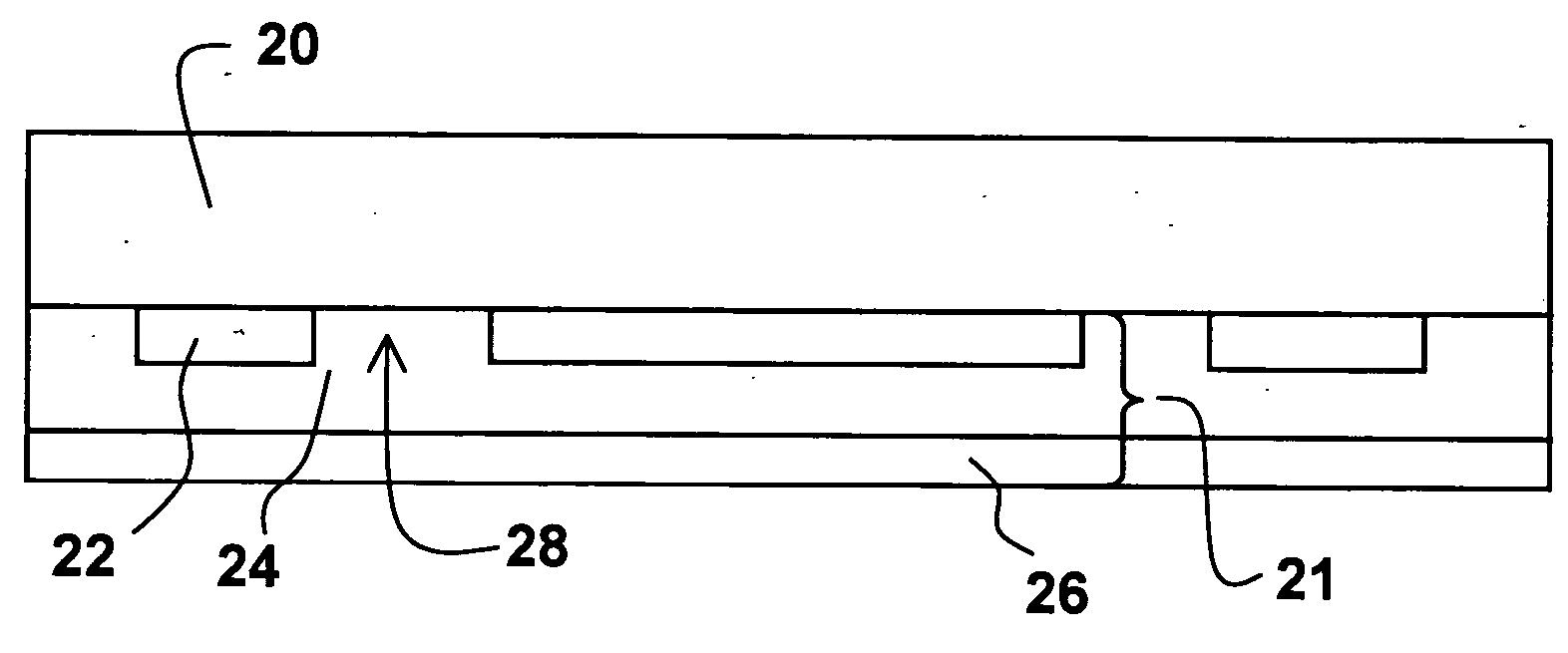

[0056] Referring now to FIG. 2 a layer of patterned aluminum 22 on a PET web 20 is shown. This embodiment is not limited to the use of aluminum as a reflector material and other reflecting materials, for example another reflecting metal could be used instead of aluminum. The PET web forms the base of the security thread upon which the layers shown are deposited; however other materials, such as other plastics could be used in place of PET. The aluminum patterned layer 22 is covered by a spacer layer 24 of MgF2 deposited over the patterned aluminum and web which forms windows 28 in regions over the web absent the deposited aluminum; a layer of absorber material 26, such as a thin layer of chromium, is deposited over the spacer layer 24. An optical interference structure is formed from the reflector / dielectric spacer / absorber (R / D / Ab) stack over the remaining portions of the patterned metal, but not over the portions of the web where the Al has been removed; these portions were Al has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com