Crosslinking of polyethylene for low wear using radiation and thermal treatments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Effect of Radiation Atmosphere and Dose on the Physical Properties of UHMWPE

[0122] Experimental Details

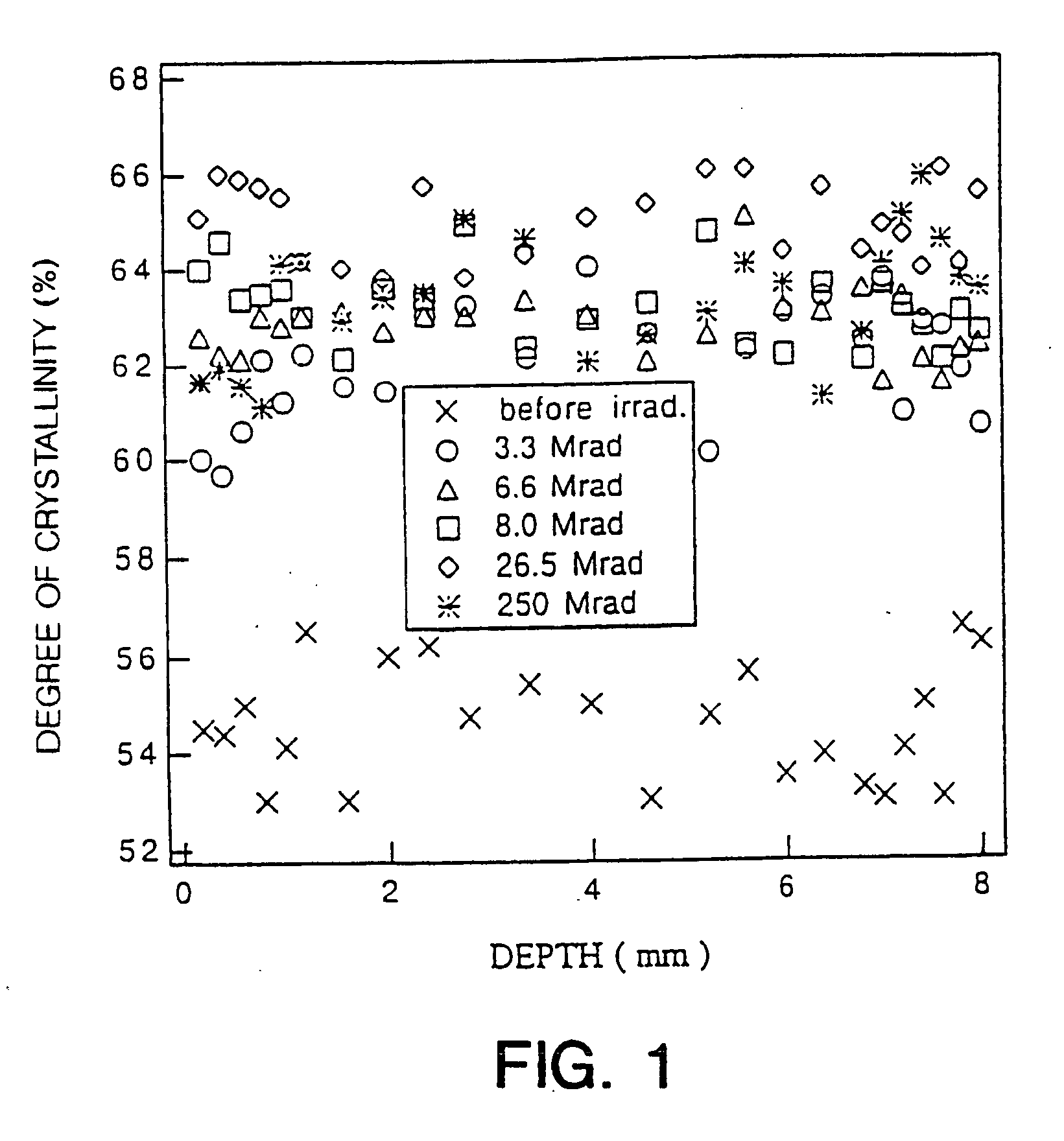

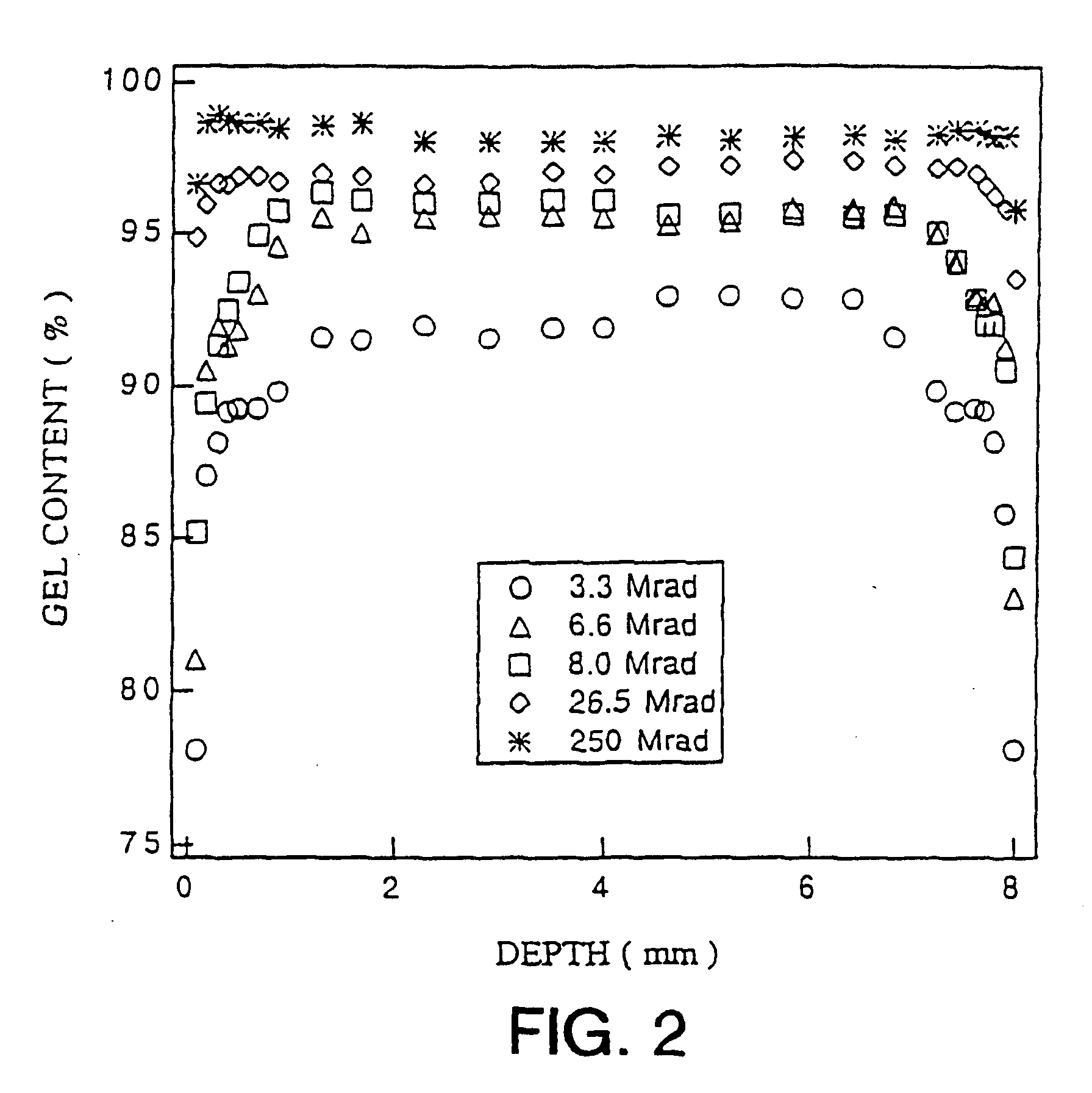

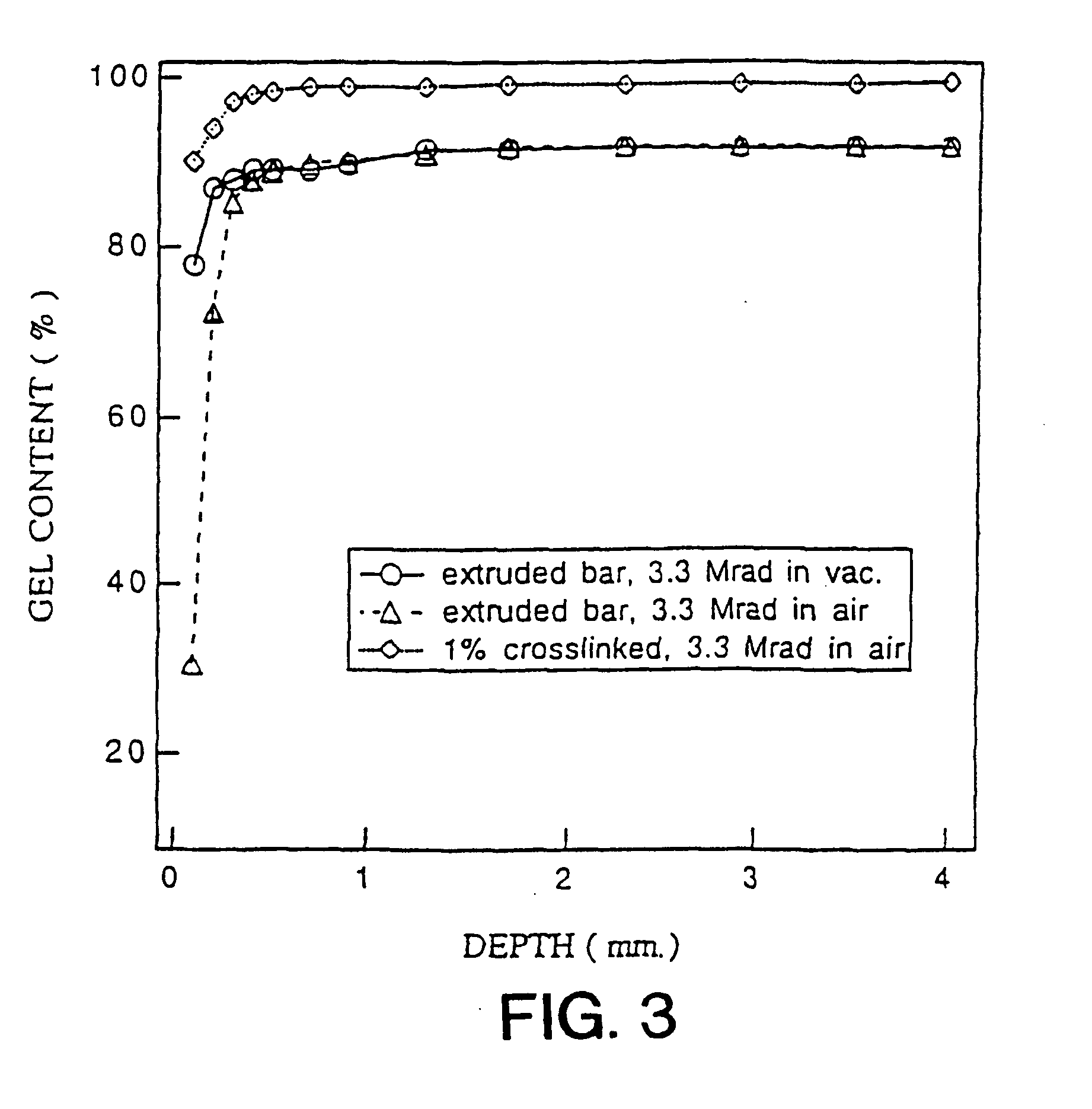

[0123] Commercial-grade UHMWPE extruded bars (GUR 4150, Poly Hi Solidur), with a weight average molecular weight of 5-6×106, were used as received. The 8 mm thick specimens were cut from the bars and irradiated with gamma-rays at room temperature either in ambient air or in a vacuum chamber at SteriGenics International (Tustin, Calif.) to average doses ranging from 3.3 to 250 Mrad. Radiation was delivered at a dose rate of 0.2 Mrad / hr. For 250 Mrad, the dose rate was 4 Mrad / hr. Cobalt-60 was used as a source of gamma radiation. A subset of the 8 mm thick specimens that had been irradiated in vacuum was remelted in a vacuum oven by heating from room temperature to 145° C. slowly (at about 0.3° C. / min.) and maintaining at 145° C. for one hour. After remelting, the specimens were slowly cooled to room temperature.

[0124] The physical properties of the disk specimens before and after...

example 2

Wear Testing of Radiation Crosslinked Cups with and without Remelting

[0135] Experimental Details

[0136] Six extruded bars of UHMWPE (GUR 4150), each 3 inches in diameter, were exposed to 3.3 or 28 Mrad of gamma radiation at a dose rate of 0.2 Mrad per hour in ambient air (SteriGenics, Inc., Tustin, Calif.). Two bars for each radiation dose were then remelted by heating in an oven in ambient atmosphere from room temperature to 150° C. at about 0.3° C. per minute and holding at 150° C. for five hours, and then slow-cooling to room temperature. The crystallinity and gel content of these four materials were measured across the cross section of extra samples of each bar using differential scanning calorimetry (DSC) and gel content analysis. The results are summarized in Tables 1 and 2.

[0137] Four sets of acetabular cups were machined from bars of each of the four materials at a commercial machining shop (Bradford and Meneghini Manufacturing Co., Santa Fe Springs, Calif.). Each cup had ...

example 3

Artificial Aging of Radiation-Crosslinked UHMWPE Materials

[0149] Six UHMWPE (GUR 4150) extruded bars (3″ diameter) were gamma irradiated in air, three bars each at 3.3 or 28 Mrad, at a dose rate of 0.2 Mrad / hour. For each radiation dose, two bars were then remelted by heating in an oven at ambient atmosphere from room temperature to 150° C. at about 0.3° C. / min, holding at 150° C. for 5 hours and slowly cooling to room temperature, and the third bar was not remelted. A 13 mm (0.5 inch) layer of the outer diameter of the treated (remelted) and untreated (non-remelted) bars was machined away to remove the most oxidized, least crosslinked surface layer. The bars were used to produce specimens for the artificial aging tests described here and for the wear tests described in EXAMPLE 2.

[0150] To examine the effect of artificial aging on these four materials (3.3 and 28 Mrad, remelted and not remelted), 8 mm thick disks were cut from these 2 inch diameter cores and were heated in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com