IC-processed polymer nano-liquid chromatography system on-a-chip and method of making it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

As employed in this patent application, the term “nano-LC” refers to a liquid chromatography system employing a column inner diameter (ID) of less than 100 μm. Where such a nano-LC system is employed with a corresponding flow rate on the order of tens to hundreds of nL / min, the system is referred to as a “nano-HPLC system”.

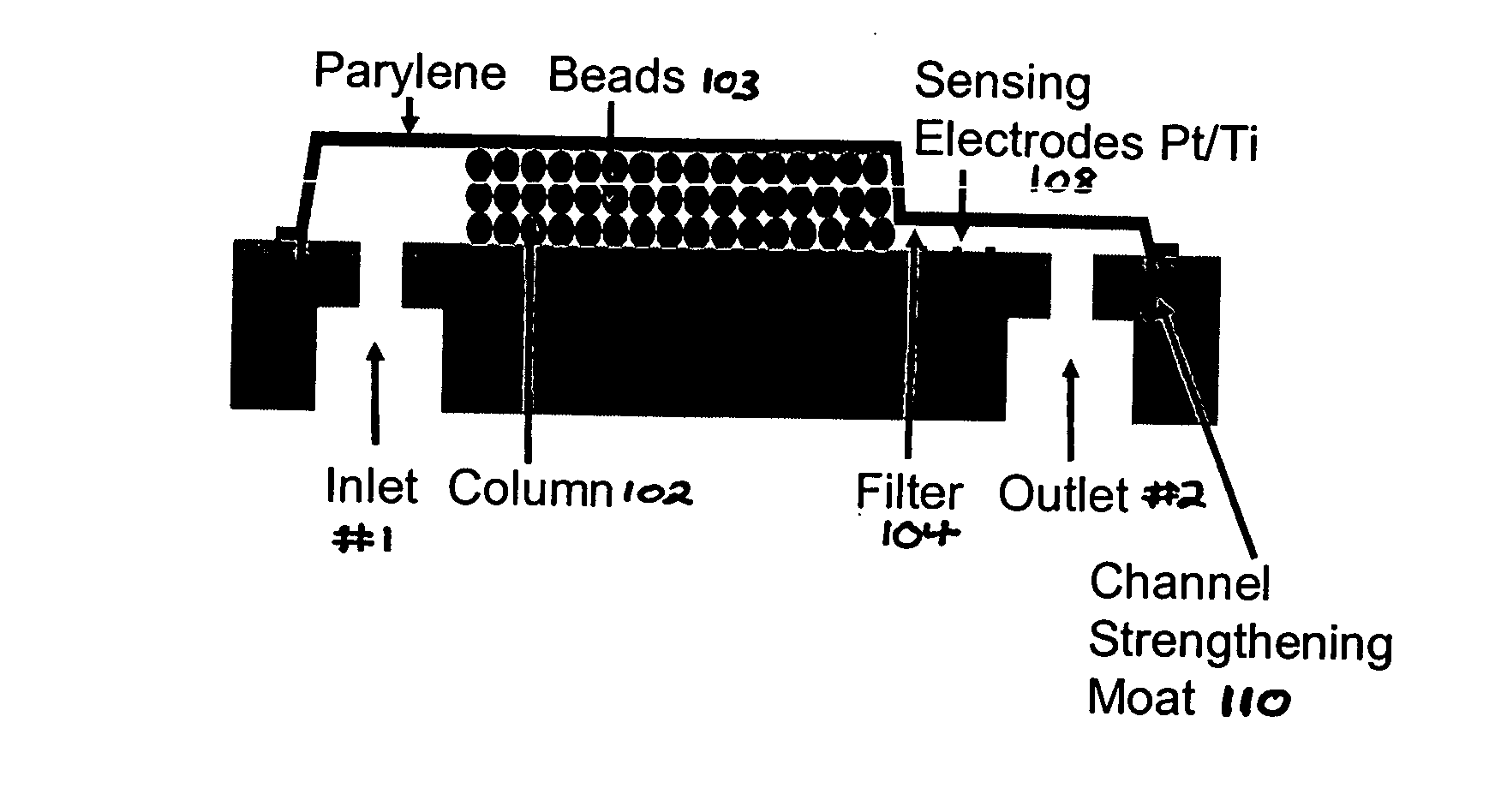

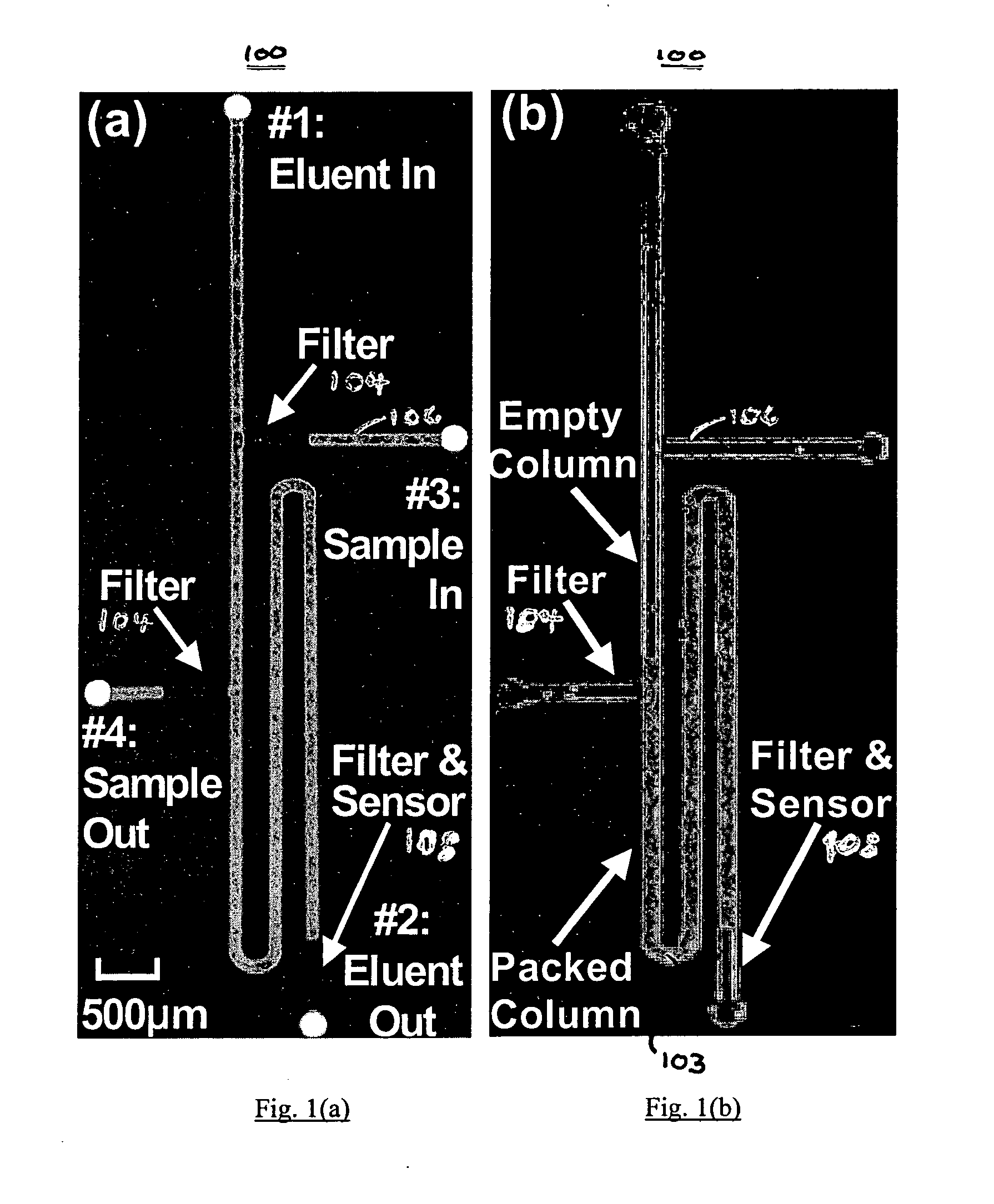

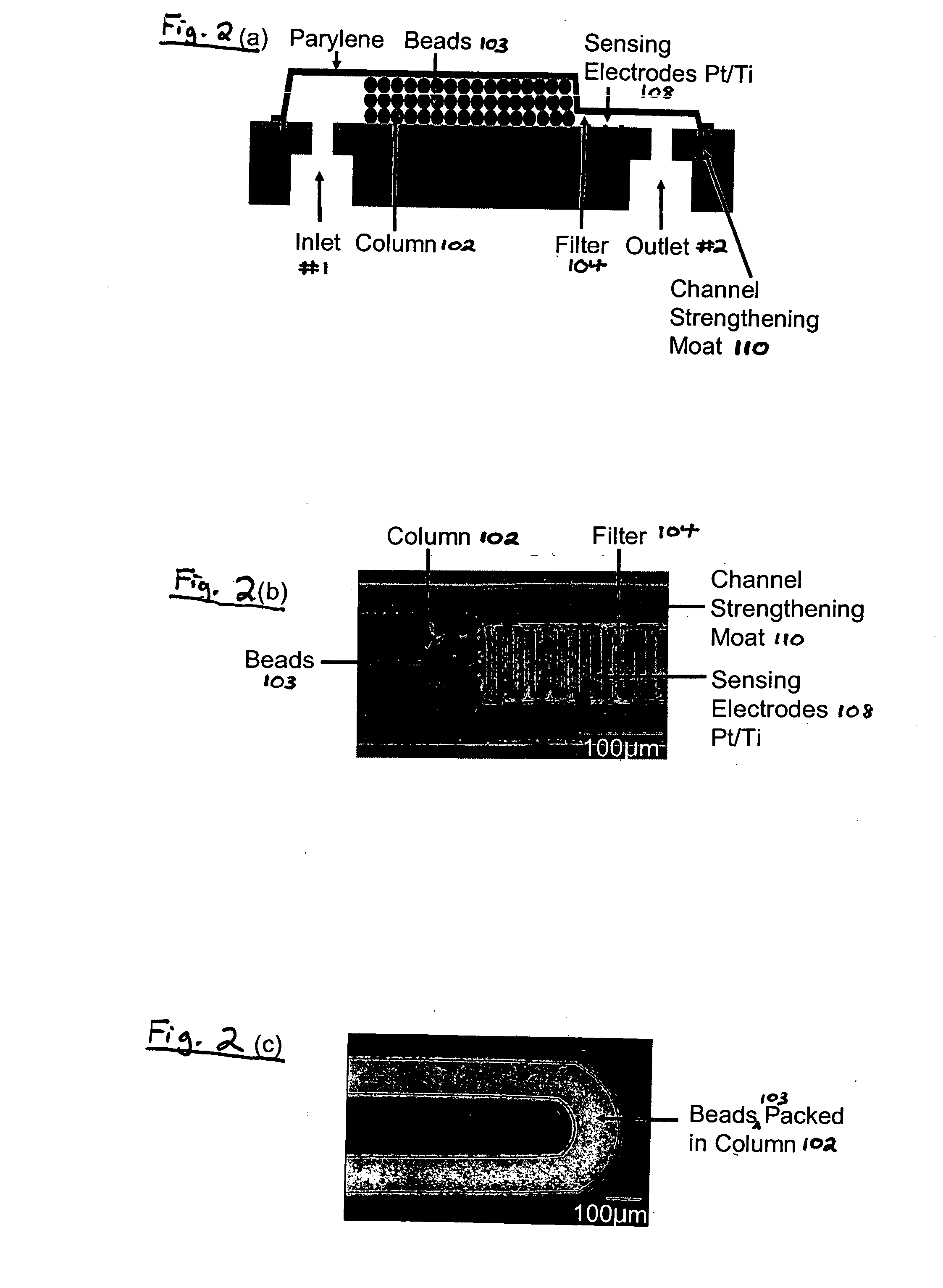

Embodiments in accordance with the present invention relate to packed-column nano-liquid chromatography (nano-LC) systems integrated on-chip, and methods for producing and using same. The microfabricated chip includes a column, frits / filters, an injector, and a detector, fabricated in a process compatible with those conventionally utilized to form integrated circuits. The column can be packed with supports for various different stationary phases to allow performance of different forms of nano-LC, including but not limited to reversed-phase, normal-phase, adsorption, size-exclusion, affinity, and ion chromatography. A cross-channel injector injects a nanolitre / p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com