Cabin air quality system

a technology for air quality systems and cabins, applied in the direction of lighting and heating apparatus, heating types, separation processes, etc., can solve the problems of vocs or svocs not being removed, adsorbent damage and inactivation of certain adsorbents, cardboard or paper support damage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0091] A PCO unit comprising two parallel PC panels was constructed. Each PC panel was 20×24 inches in cross section, and the two PC panels were spaced five inches apart. The panels were coated with photocatalyst as described in commonly assigned U.S. patent application Ser. No. 10 / 345,022, filed Jan. 14, 2003, the disclosure of which is incorporated by reference herein in its entirety. Two 36 W UV lamps were positioned midway between the two PC panels. An air stream containing acetaldehyde (inlet concentrations in the range of 0.147 to 0.331 ppmw) was passed through the PCO unit. The air temperature of the air stream was in the range of 79-85° F., and the relative humidity was in the range of 35-48%.

[0092] Sampling ports were arranged so as to allow sampling of the air stream at both the inlet and the outlet of the PCO unit. The air so sampled was pumped to the injection port of a gas chromatograph for analysis of acetaldehyde concentration. Samples were taken from the outlet both...

example 2

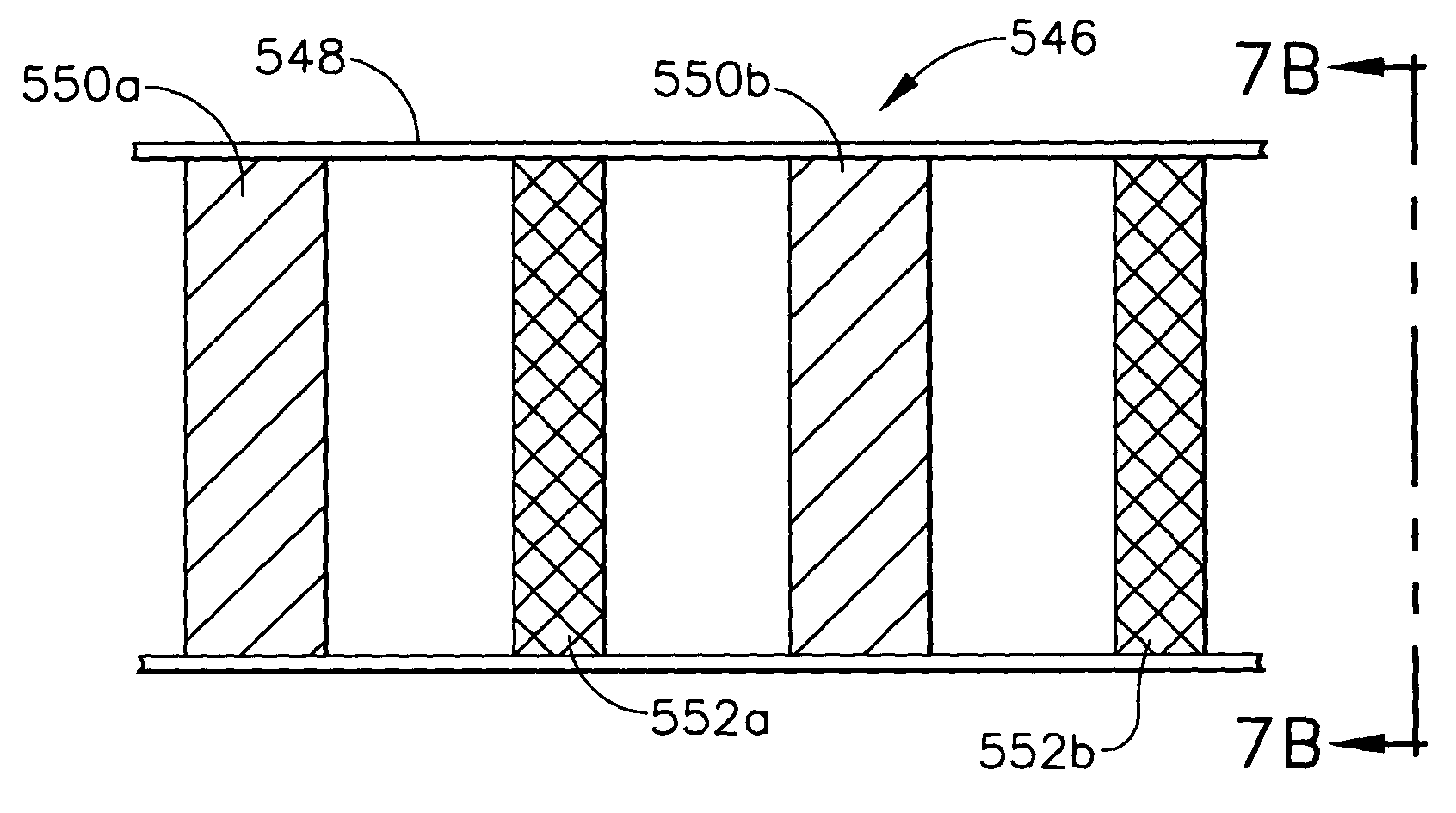

[0093] A PCO unit comprising five parallel PC panels was constructed. Each panel was 20×24 inches in cross section, and the PC panels were spaced three inches apart. Two 36 W UV lamps were mounted between each successive pair of PC panels for a total of eight UV lamps. An air stream contaminated with low concentrations of acetaldehyde was passed through the PCO unit. The air temperature was 85° F., and the relative humidity was 21%. Air was sampled and analyzed by gas chromatography, essentially as described in Example 1. Table 3 reports average values of several measurements for each condition. The % removal of acetaldehyde from the air stream was calculated by comparing the “lights OFF” and “lights ON” conditions.

TABLE 3Removal of Acetaldehyde from an Air Stream via a PCO Unit havingFive PC panelsOutlet conc.Outlet conc.lights OFF,lights ON,(ppmw)(ppmw)% Removal+ / −0.7320.64511.86%1.82%0.5450.45915.75%3.25%0.3650.32112.13%1.88%0.2910.22223.70%11.67%0.2050.12140.97%5.74%0.1960.165...

example 3

[0095]FIG. 10 shows the results of a number of experiments performed using the PCO units described in Examples 1 and 2. The flow rate of the air stream for these experiments was 500 cfm. For each experiment, the % removal of acetaldehyde from the air stream was normalized by the number of PC panels to express the data as fractional removal / panel. The equation used for this normalization was: Fractional removal / panel=1-ⅇ(ln(1-R)P),

[0096] It is apparent from FIG. 10 that fractional removal per panel tends to be higher at lower concentrations of acetaldehyde, and lower at higher concentrations. A PCO unit of the type described in Examples 1 and 2 will therefore function well with a steady low concentration of pollutant in the feed air stream. Such a feed may be experienced, for example, when an upstream adsorbent unit initially adsorbs any pulse(s) of pollutant, and subsequently desorbs the pollutant to the PCO unit at a manageable rate, generally as described hereinabove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| constant temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com