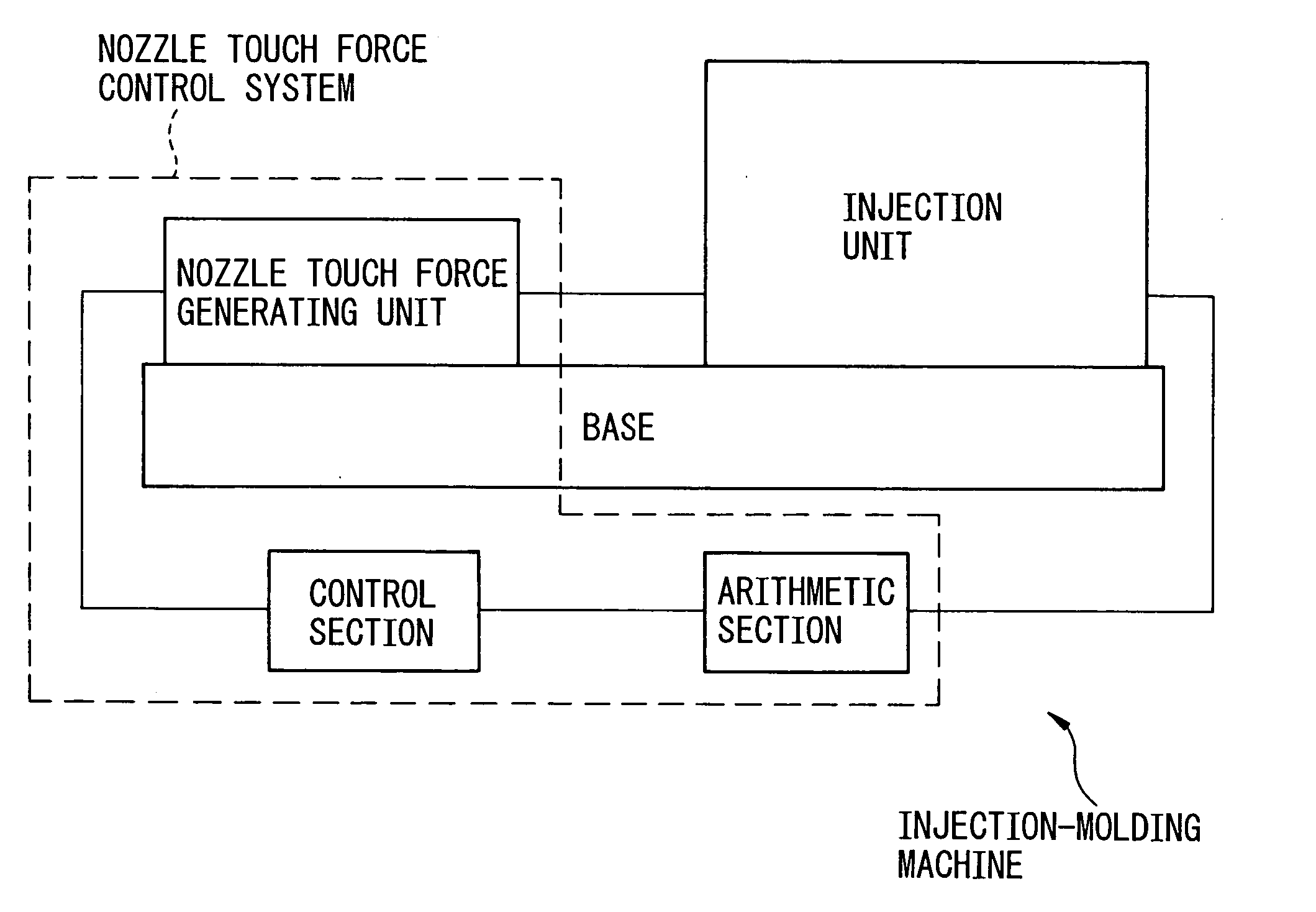

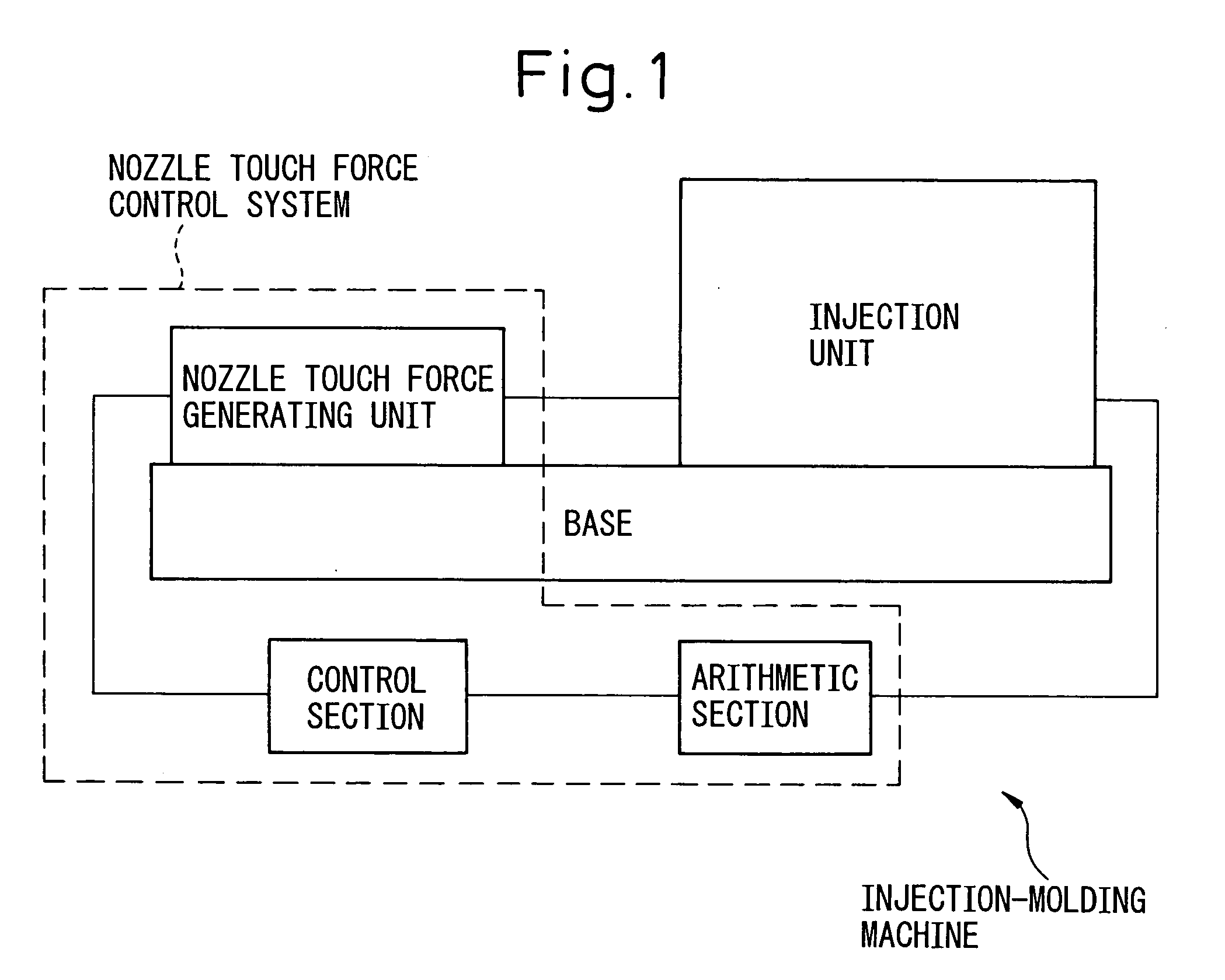

System for controlling nozzle touch force

a technology of touch force and nozzle, which is applied in the field of injection molding machines, can solve the problems of further dropping the quality of the molded article, and reducing the life of the metal mold, so as to achieve the effect of simple structure and easy maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

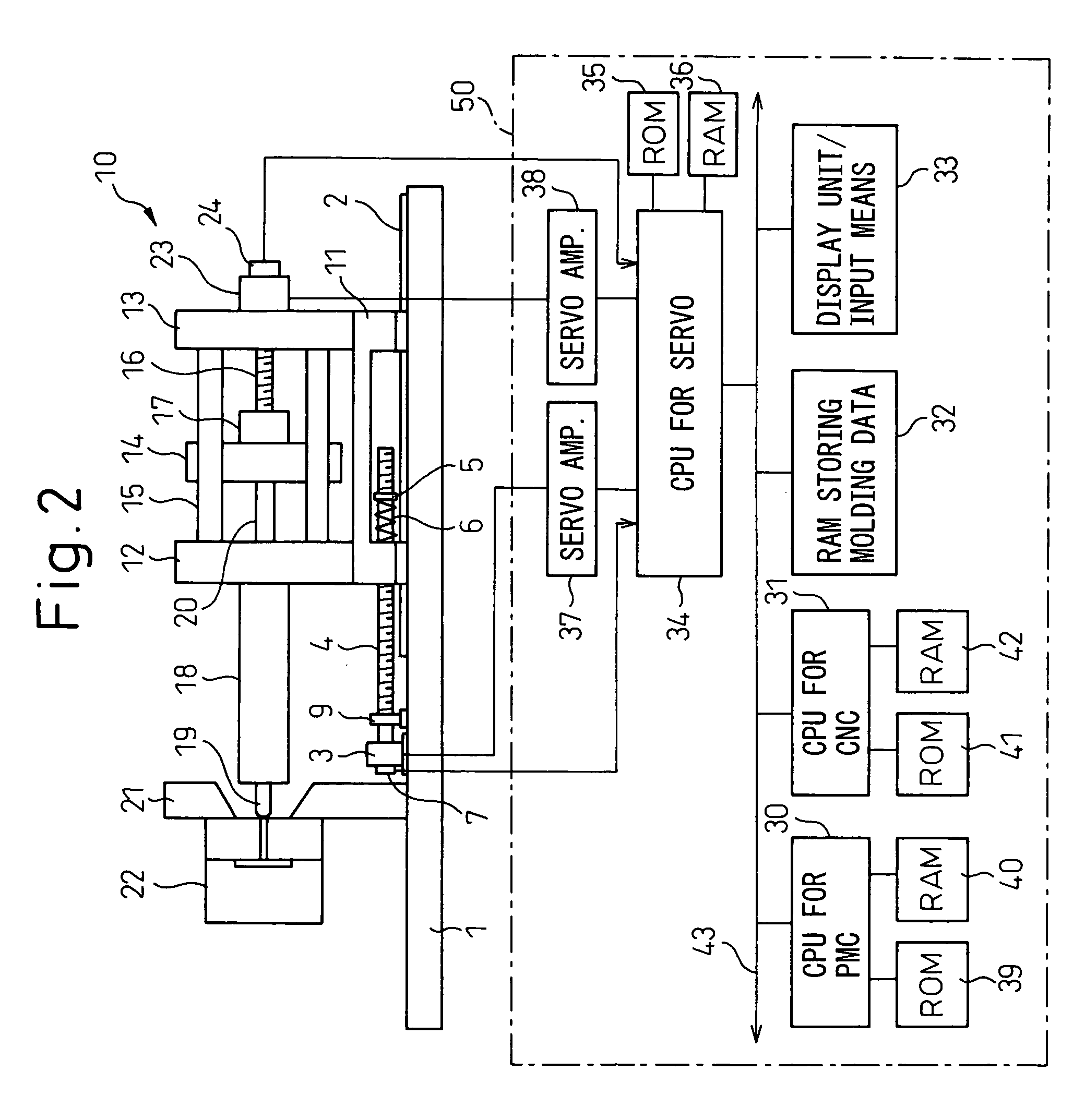

first embodiment

[0033]FIG. 2 is a diagram illustrating a major portion according to the present invention. As shown, on a rail 2 provided on the base 1 of the injection-molding machine, there is arranged a unit base 11 that constitutes a portion of the injection unit 10 so as to move back and forth. An injection mechanism is mounted on the unit base 11 so as to be turned for the replacement and maintenance of the injection screw. The injection mechanism includes a front plate 12, a rear plate 13, and a pusher plate 14 guided by a plurality of guide bars 15 coupling the front plate 12 and the rear plate 13 together, and a nut 17 is secured to the pusher plate 14 so as to be screwed onto a ball screw 16 for injection. The pusher plate 14 rotatably holds an injection screw 20 that is inserted in the heating cylinder 18. A nozzle 19 is provided at an end of the heating cylinder 18, and is allowed to come in contact with, or separate away from, a metal mold 22 mounted on a stationary platen 21. A servo ...

second embodiment

[0054] In the second embodiment, the CPU 30 for PMC sends a torque instruction To corresponding to a preset nozzle touch force to the motor 3′ of which the torque can be controlled through the CPU 34 for servo and the amplifier. Being driven by the electric motor 3′, the ball screw rotates, the injection unit moves forward due to the nut screwed onto the ball screw, and the nozzle 19 comes in contact with the metal mold 22. When the injection unit 10 is no longer moved, the electric motor 3′ produces the torque T0 as instructed, and the nozzle touch force is maintained at the preset nozzle touch force.

[0055]FIG. 5 is a flowchart of a nozzle touch force control processing executed in the injection / pressure-maintaining step at regular intervals according to the second embodiment of the present invention. In the injection / pressure-maintaining step, the CPU 30 for PMC executes the same processings as those of the steps 100 to 102 of the first embodiment, reads the speed V of injection, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| acceleration | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com