Smoking apparatus for processing porkhide dog chews

a technology of porkhide and apparatus, which is applied in the field of processing animal hide pet food products, can solve the problems of no dyeing or flavoring, no way to dye or flavor, and rough appearance of porkhide dog chews

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

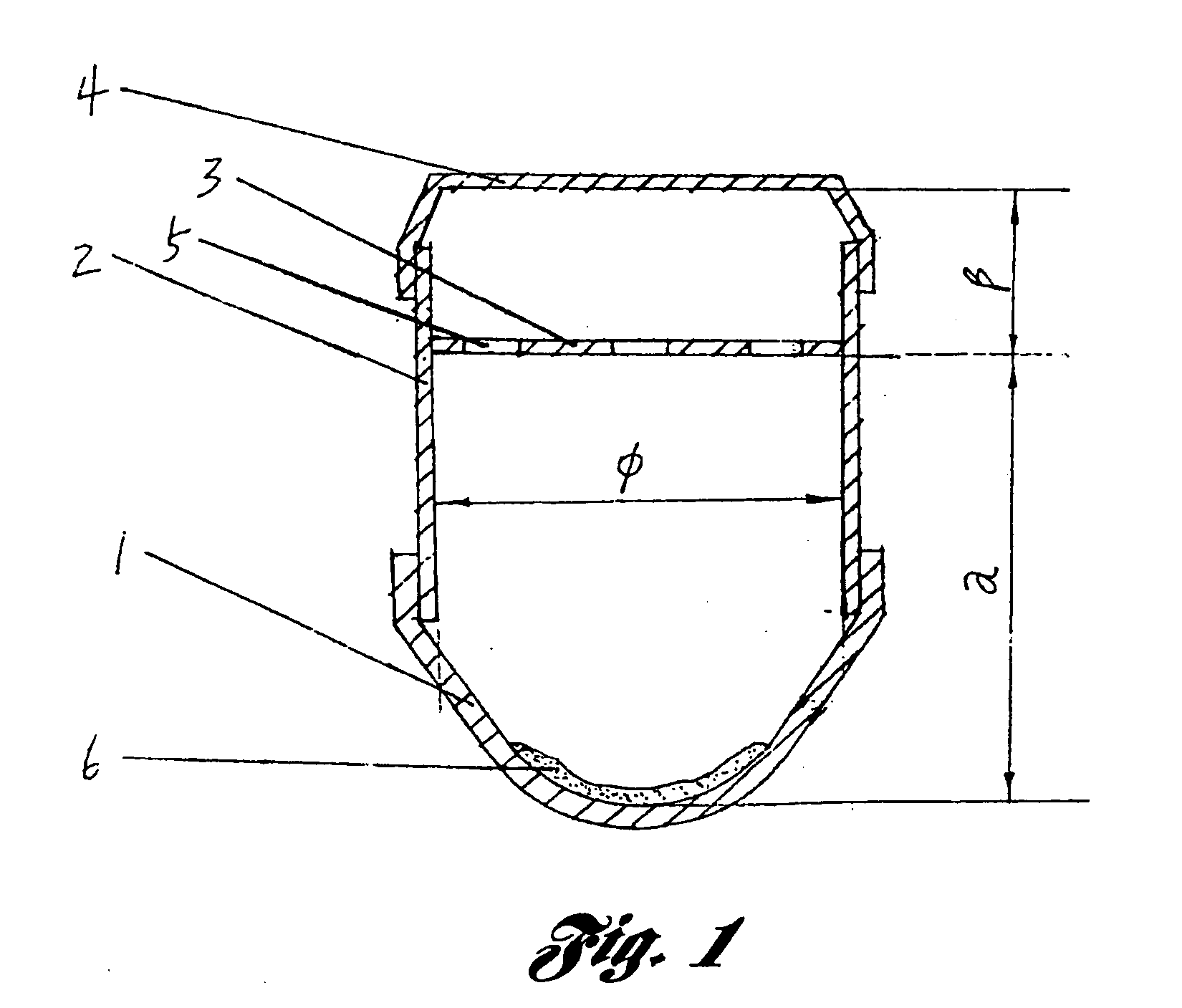

Image

Examples

Embodiment Construction

[0014] Hide material for shaped porkhide products has large pores, which are easily penetrated by smoke. It absorbs heat and absorbs smoke more readily than other hides such as cowhide. When combined with smoke the resulting odors are very pleasant. At the same time, the surface of shaped porkhide products is greasy. In situations where the general direct dyeing and flavoring methods prove ineffective, the surface grease is heated and melted, enabling the smoke to act on the shaped product while it is greasy so as to give it a bright luster while dyeing it.

[0015] Cowhide dog chews are suited to direct dyeing and flavoring because their hide materials have small pores and small amounts of grease, and for many years, the industry had a fixed way of thinking, or conceptual inertia: whenever one thought of changing the smell or color of a dog chew, one would think of directly dyeing and flavoring, i.e. of relying on the direct action of food dyes and, flavor essences on finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com