Hydrogen storage container

a technology for storage containers and hydrogen, applied in the direction of gas/liquid distribution and storage, containers, large containers, etc., can solve the problems of localized stress on the container, decrepitation of metal hydride particles, etc., and achieve the effect of preventing ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

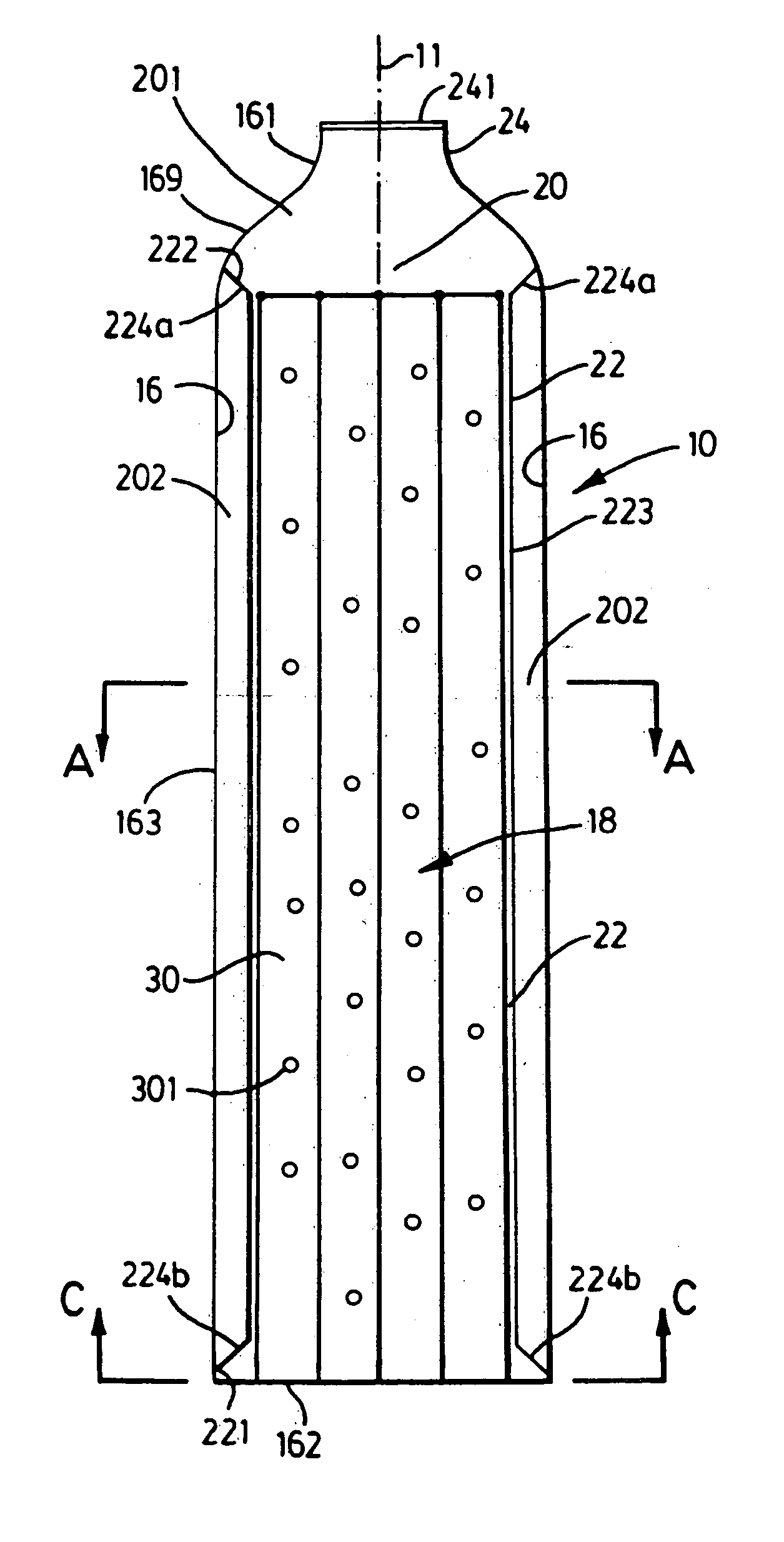

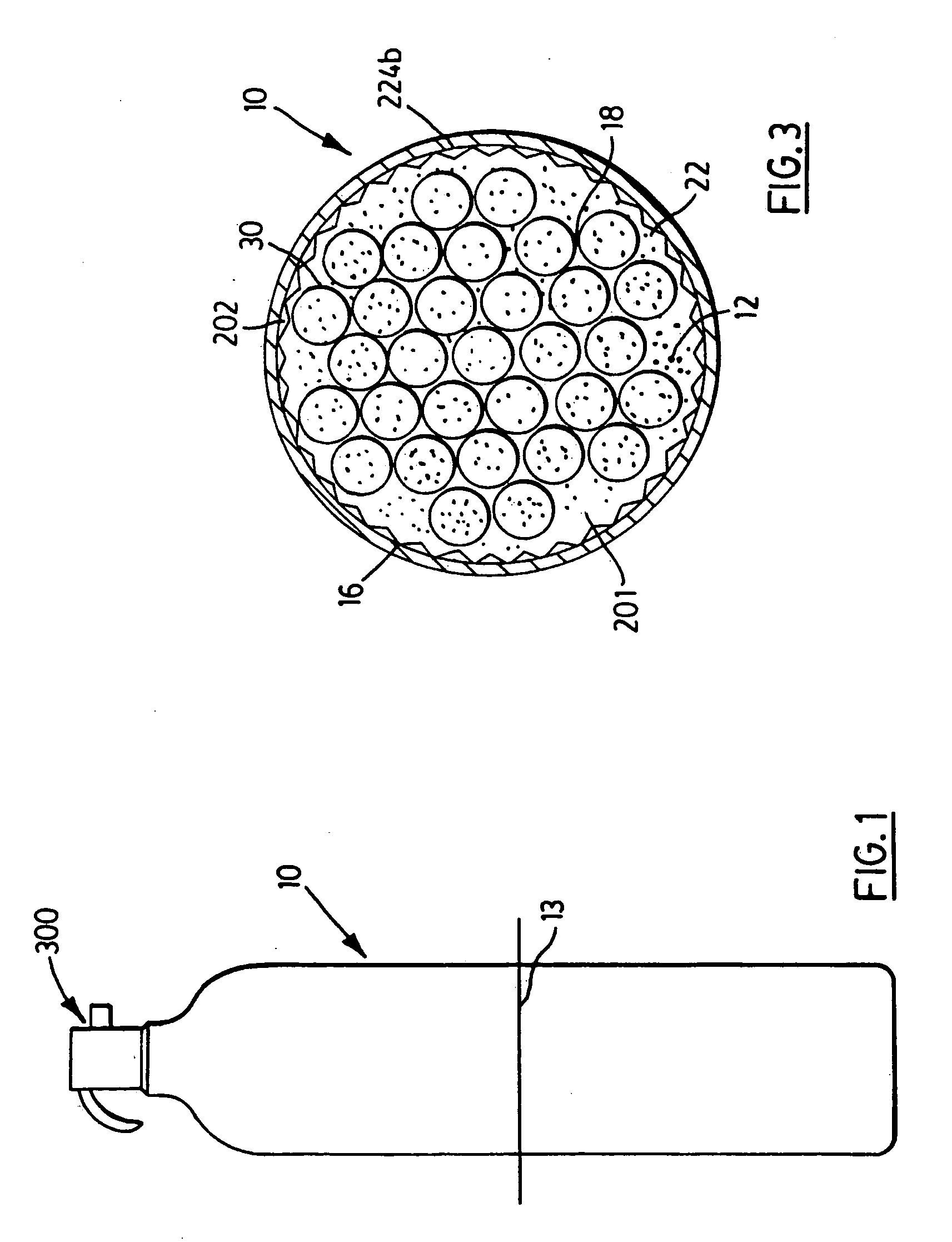

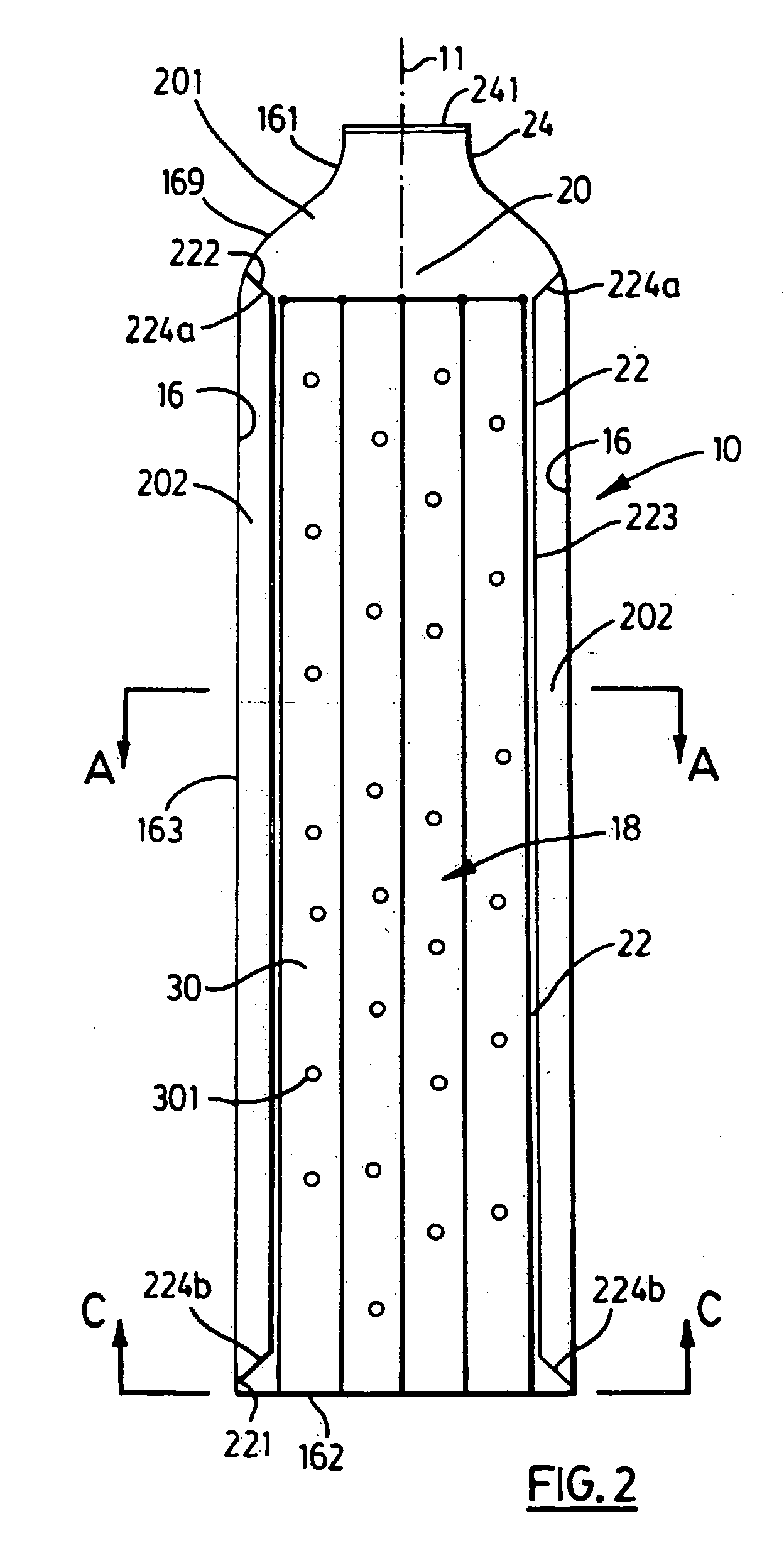

[0052] Referring to FIGS. 1 and 2, the present invention provides a container 10 for containing metallic particles 12 capable of forming metal hydrides.

[0053] The interior space 20 of the container 10 receives metallic particles 12 capable of forming metal hydrides. The metallic particles 12 are in the form of a powder. An example of a suitable particle size of the powder is within the range of one micron to 3000 microns. The metallic particles 12 must be capable of absorbing hydrogen (also known as “charging”) to effect storage of hydrogen in the form of a metal hydride. Further, such metallic particles 12, after having absorbed hydrogen, (in the form of a metal hydride) must be capable of desorbing hydrogen (also known as “discharging”) upon demand from an unit operation, such as when required for use as a fuel in a fuel cell or in an internal combustion engine. Upon absorbing hydrogen, the metallic particles 12 expand, and thereby increase the volume occupied. During desorption,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com