Baths, methods, and tools for superconformal deposition of conductive materials other than copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

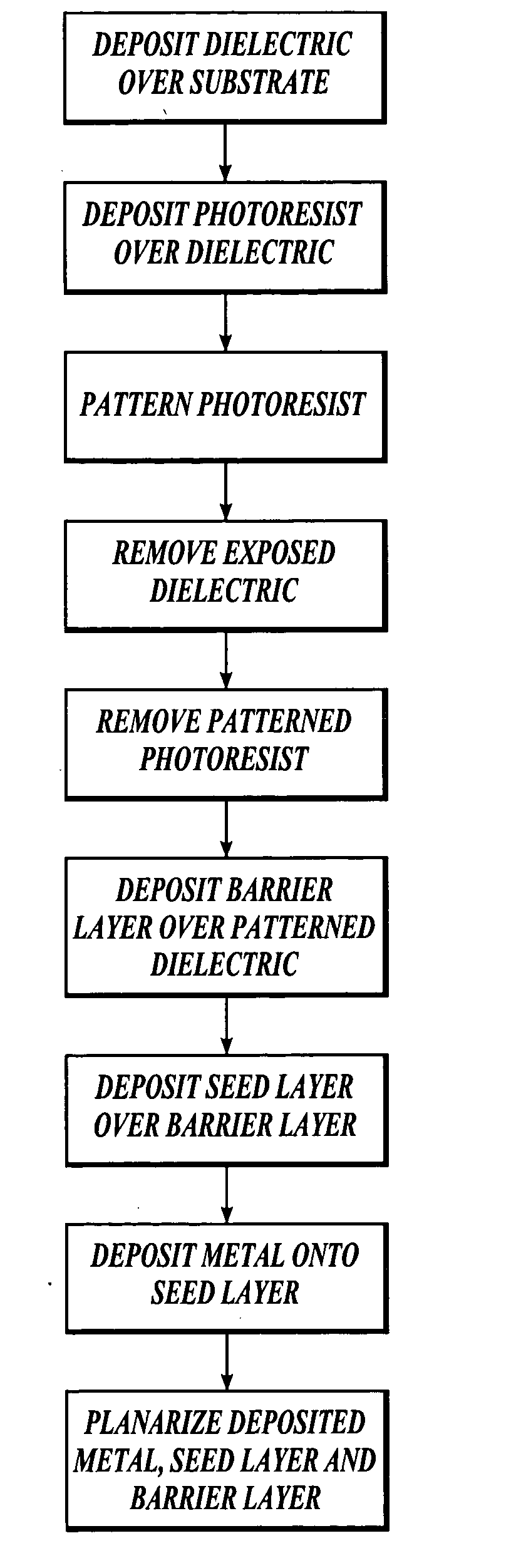

Method used

Image

Examples

example

Superconformal Electrolytic Deposition of Gold into Patterned Features

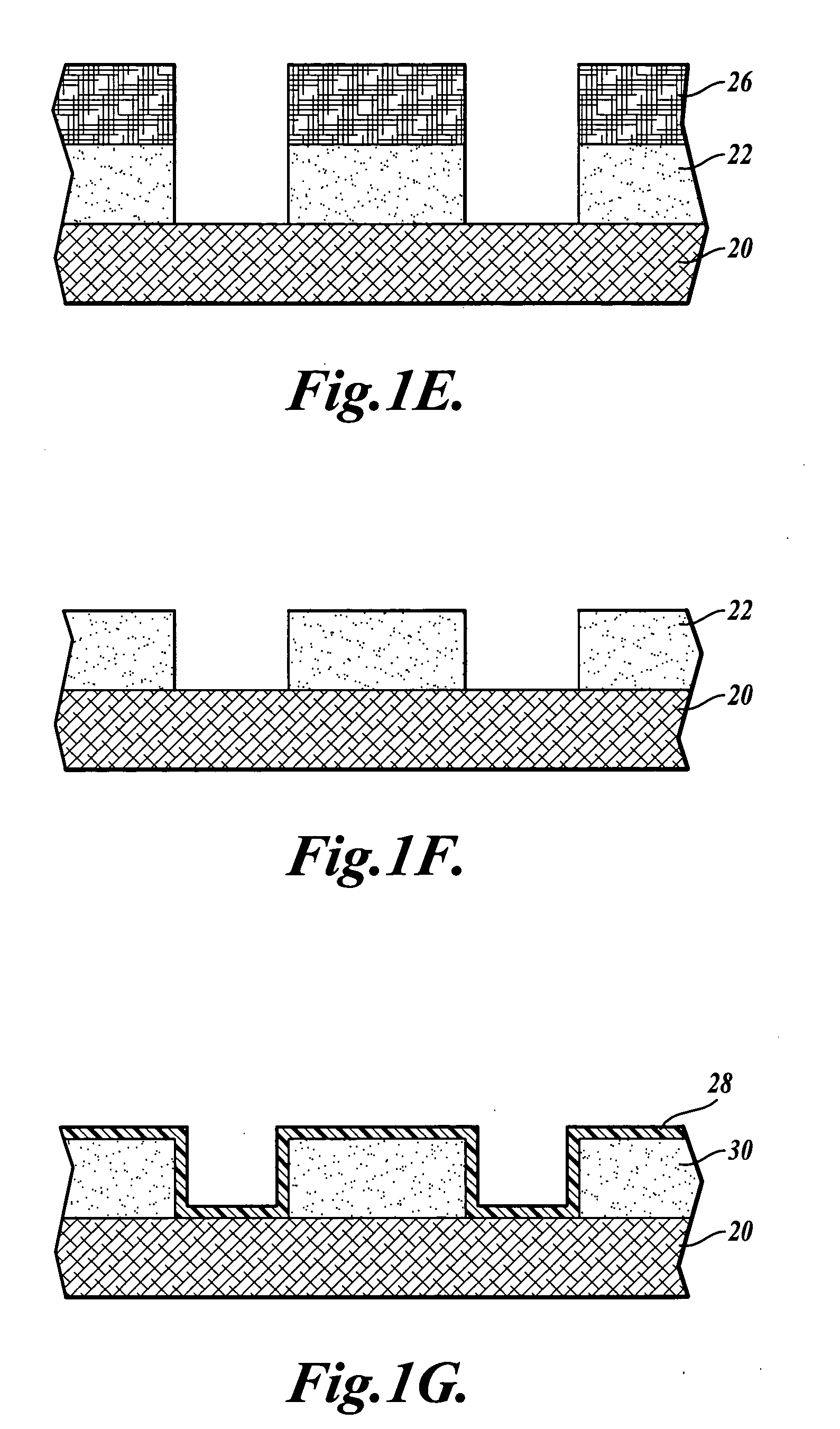

[0053] In this example, a silicon wafer including patterned features having a feature depth of 3.8 μm and an aspect ratio of 4:1 was processed to deposit gold into the patterned features superconformally. The patterned features included a titanium-based barrier layer 500 Å thick and a gold seed layer 500 Å thick. The titanium-based barrier layer and gold seed layer were deposited by sputtering. The wafer was contacted with the electroplating bath in an Equinox® brand single wafer plating tool available from Semitool, Inc. of Kalispell, Mont. The plating tool included an inert platinum anode. The plating was carried out at 50° C. The chemical flow rate was 3.5 gpm and the wafer was rotated at 40 rpm. The electroplating power was pulsed with 2 ms on and 8 ms off. The peak current density was 8 mA / cm2 and an average current density was 1.6 mA / cm2. This resulted in a plating rate of about 0.1 μm per minute.

[0054] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Substance count | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Deposition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com