Scanning system for inspecting anamolies on surfaces

a scanning system and anamoly technology, applied in the field of surface inspection systems, can solve the problems of undetectable background, affecting the uniformity of the spot along the scan line, and reducing the size of the illuminated area, so as to reduce the size of the illuminated area and reduce the scattering of light. , the effect of reducing the size of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

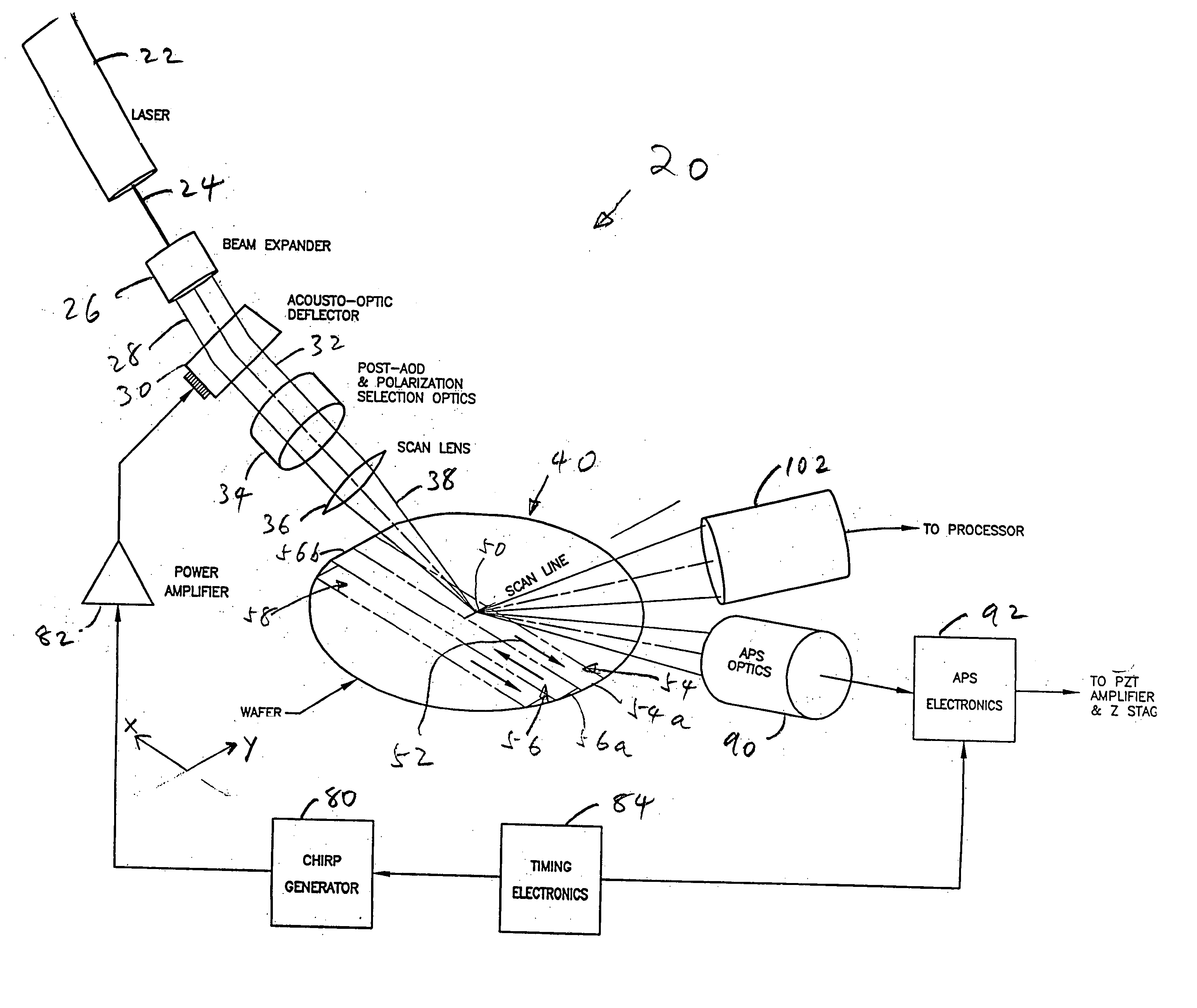

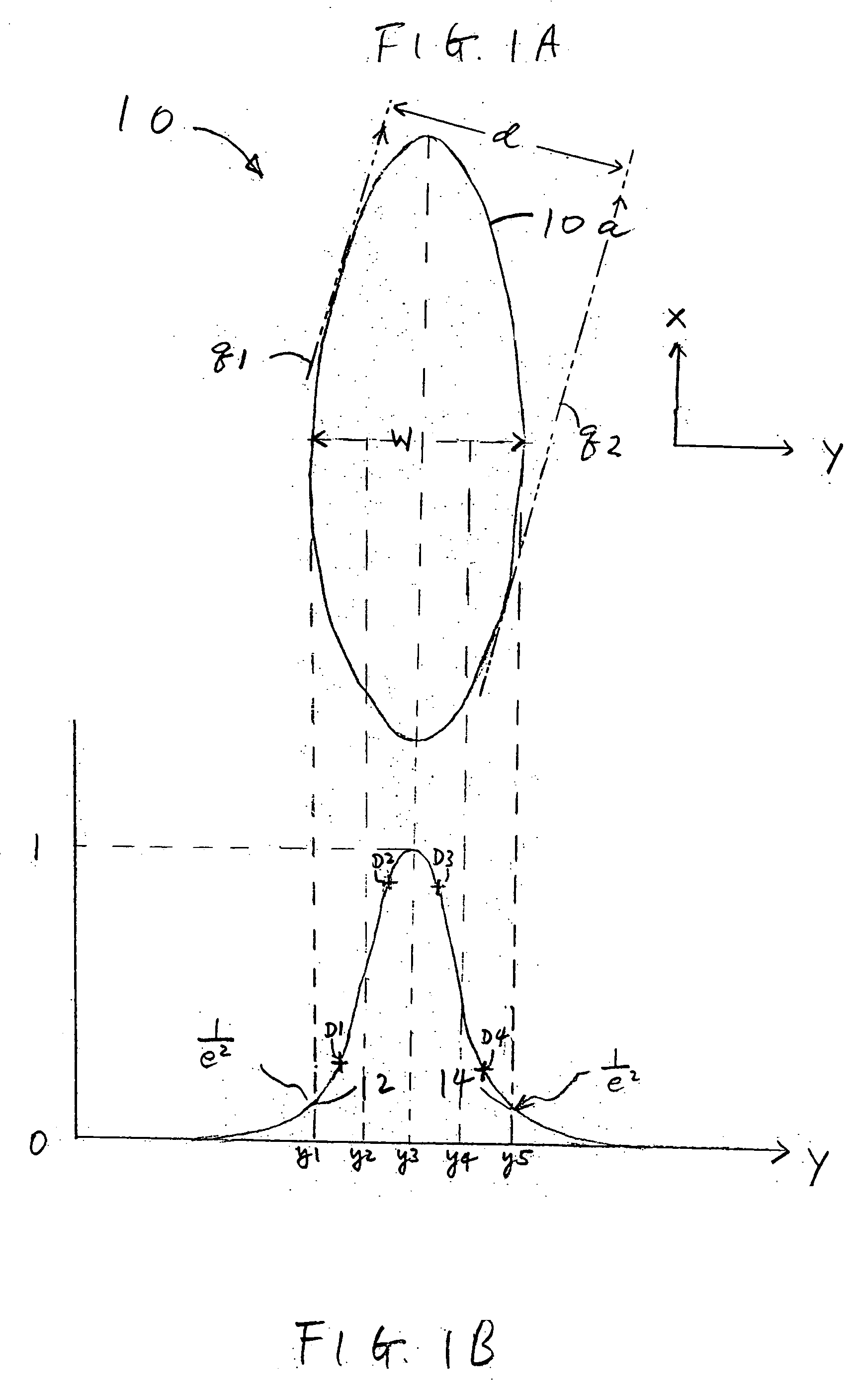

[0038]FIG. 1A is a schematic view of an elliptical-shaped illuminated area (or spot) of a surface inspected by the system of this invention to illustrate the invention. As explained below, the laser beam illuminating the surface inspected approach the surface at a grazing angle, so that even though the illumination beam has a generally circular cross-section, the area illuminated is elliptical in shape such as area 10 in FIG. 1A. As known to those skilled in the art, in light beams such as laser beams, the intensity of the light typically does not have a flat distribution and does not fall off abruptly to zero across the boundary of the spot illuminated, such as at boundary 10a of spot 10 of FIG. 1A. Instead, the intensity falls off at the outer edge of the illuminated spot at a certain inclined slope, so that instead of sharp boundaries such as boundary 10a illustrated in FIG. 1A, the boundary is typically blurred and forms a band of decreasing intensity at increasing distance away...

PUM

| Property | Measurement | Unit |

|---|---|---|

| azimuthal angle | aaaaa | aaaaa |

| azimuthal angle | aaaaa | aaaaa |

| azimuthal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com