Photoconductive optical write driver for magnetic recording

a write driver and photoconductive technology, applied in the direction of mounting head within the housing, track selection/addressing details, instruments, etc., can solve the problems of limiting the data rate transmission of conventional data rate transmission, interconnection between write electronics, and the capability of existing silicon-based write drivers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

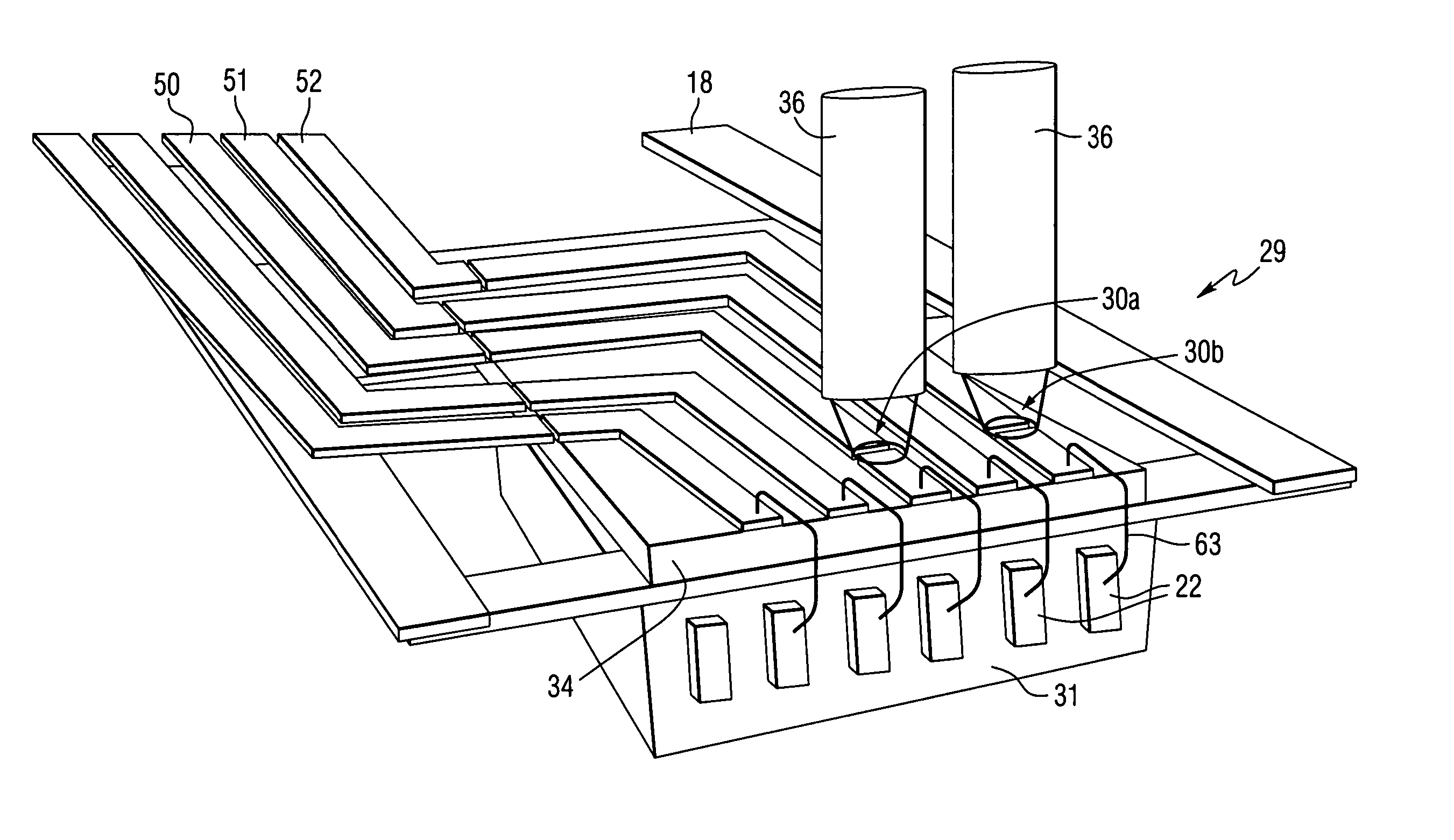

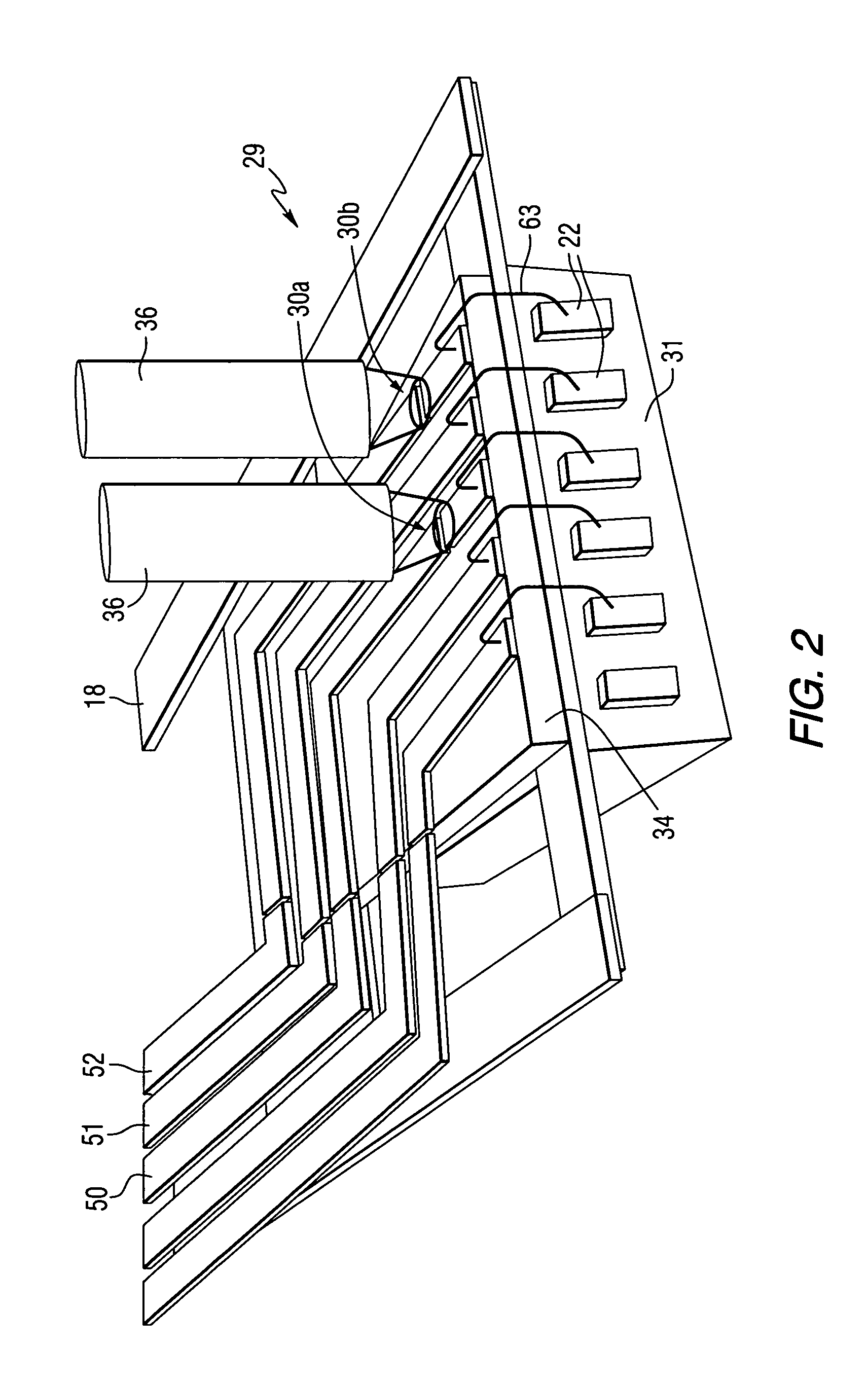

[0038] In an example of the present invention, as shown in FIG. 2, the semiconductor switch is fabricated on LT-GaAs having properties to reduce the switch resistance from infinity to about 50 Ω when the switch is illuminated with reasonable average power from a diode laser. An example of the carrier mobility, or electron mobility, of a representative LT-GaAs composition is

μn=4000 cm2V−1s−1.

For an average laser power of 20 mW, i.e. a high photogeneration rate, the resultant carrier density is

n=3×1014 cm−3.

The electrical conductivity is

σ=neμn

σ=0.19 Ω−1 cm−1,

where e is the electron charge. Inverting this equation to obtain resistivity,

ρ=5.2 Ωcm.

For a switch geometry, as shown in FIGS. 6-7, with a 1 μm thick LT-GaAs film and 100 μm long electrodes, with 100 nm between the electrodes, this yields an on-state switch resistance of R=52 Ω. Assuming that the current through the switch saturates at Vbias=5V, the current output from one of the switches in FIG. 2 is,

ISW=Vsat / Ron-...

example 2

[0039] In another example, carrier lifetimes with other LT-GaAs compositions as short as 100 fs are obtainable, however, they require increased laser power to obtain a similar switch resistance due to their lower carrier mobility and concentration values. For materials wherein μ=2000 and the carrier lifetime=100 fs, from the Example 1 calculation, R=31 kOhms for a 40 mW average power linear photogeneration rate, for materials having a 400 μm border length and 200 μm thickness. For μ=3200 cm2V−1s−1, the lifetime=50 ps. From the Example 1 calculation, R=78 kOhms. By increasing the wire thickness and the border length of the electrodes to 2 μm and 400 μm respectively, R=100 Ohms. If the laser power is doubled to 80 mW average power having a linear increase in the photogeneration rate, R=50 Ohms.

example 3

[0040] In another example, a modulator driver with 10 ps risetimes and 40 Gbit / sec data rate capability with high voltage output can be used for driving a lithium-niobate or other type of modulator, which modulates or encodes the laser output to obtain the desired optical write waveform. Lithium-niobate modulators are commercially available devices which can turn a continuous laser output of 20 mW into a square wave light output with 10 ps response times and 40 Gbit / sec data rate capability. By using the 80 ps response time of LT GaAs with a 20 mW laser, a 100 mA current can be modulated at frequencies approaching 5 GHz, which corresponds to a data rate of 10 Gbit / sec. In this example, the data rate of 10 Gbit / sec is limited by the 80 ps risetime. By turning a continuous laser output of 40 mW into a square wave light output with a 50 ps response time, a 100 mA current can be modulated at frequencies approaching 7 GHz, which corresponds to a data rate of 14 Gbits / sec. This correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com