Indexing rotatable chuck for a probe station

a rotary chuck and probe station technology, applied in the direction of individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of achieve the effect of promoting rigidity and consistent planarity, reducing shaft length, height and mass of the rotary chuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

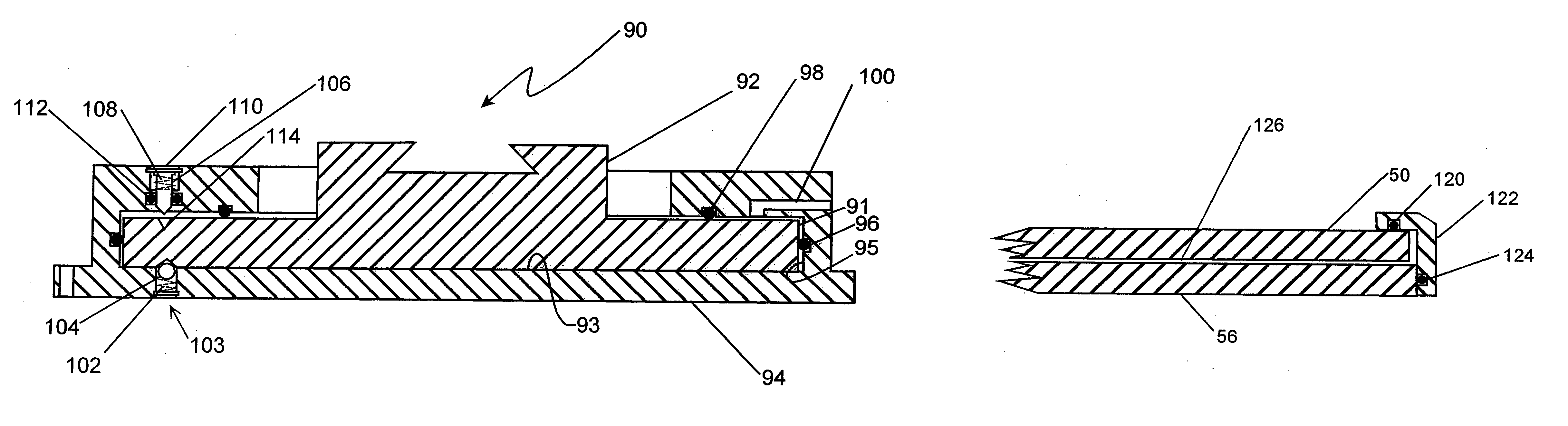

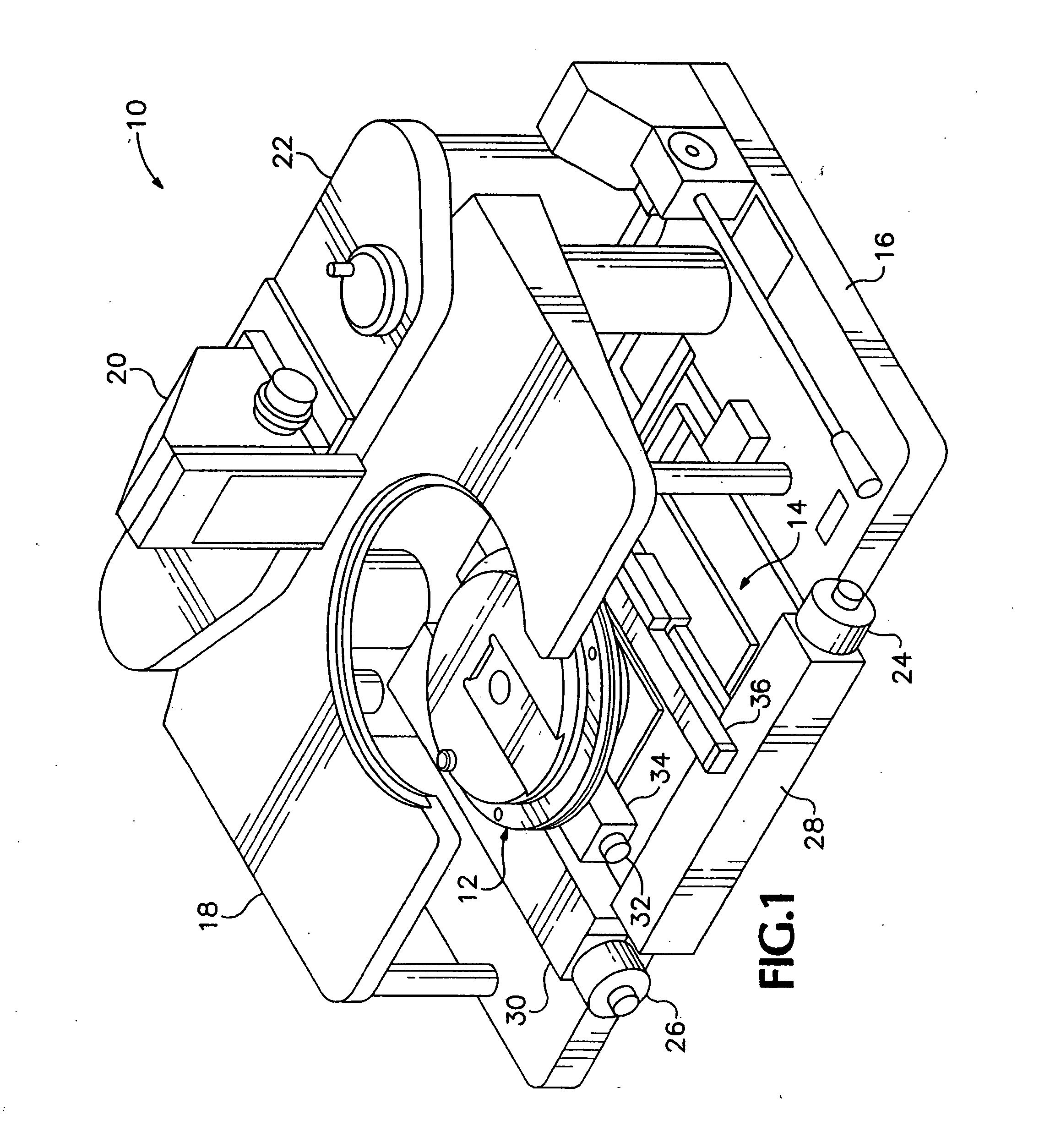

[0017] Referring to FIG. 1, in a probe station 10 a device under test (DUT) is mounted on a chuck 12 which is supported on a movable stage 14 mounted on a station base 16. Probes (not illustrated) are supported over the chuck by a platen 18. The probes are provided with controls for positioning along horizontal (x and y) axes and the platen 18 may be adjusted in the vertical (z) direction to bring the probes into contact with test points on the integrated circuit of the DUT. To facilitate location and positioning of the probes, the probe station 10 includes a microscope (not illustrated) mounted on a microscope mounting 20 attached to an optics bridge 22. The probe station 10 may include an environmental housing (not illustrated) to protect the DUT and probes from dust and other environmental hazards.

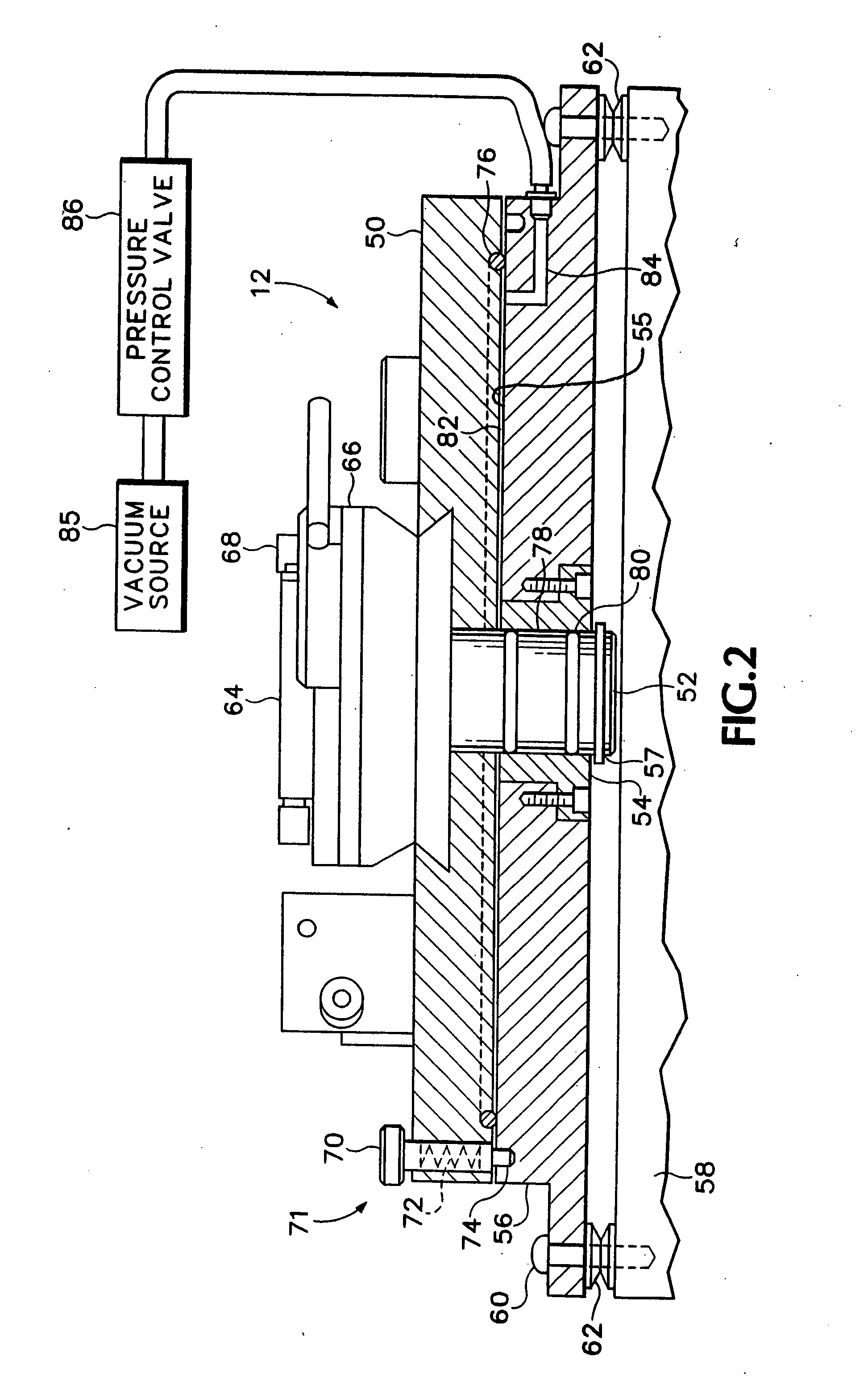

[0018] To facilitate relative positioning of the DUT and probes, the stage 14 provides for translatory and limited rotational (theta) movement of the chuck 12. In the probe station 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com