Decomposition apparatus of organic compound, decomposition method thereof, excimer UV lamp and excimer emission apparatus

a technology of organic compound and decomposition apparatus, which is applied in the direction of discharge tube/lamp details, discharge tube main electrodes, energy-based chemical/physical/physicochemical processes, etc. it can solve the dilemma of how to solve the problem, the recycling treatment of activated carbon and the maintenance of the apparatus are not easy, and achieve excellent permeability of the uv light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

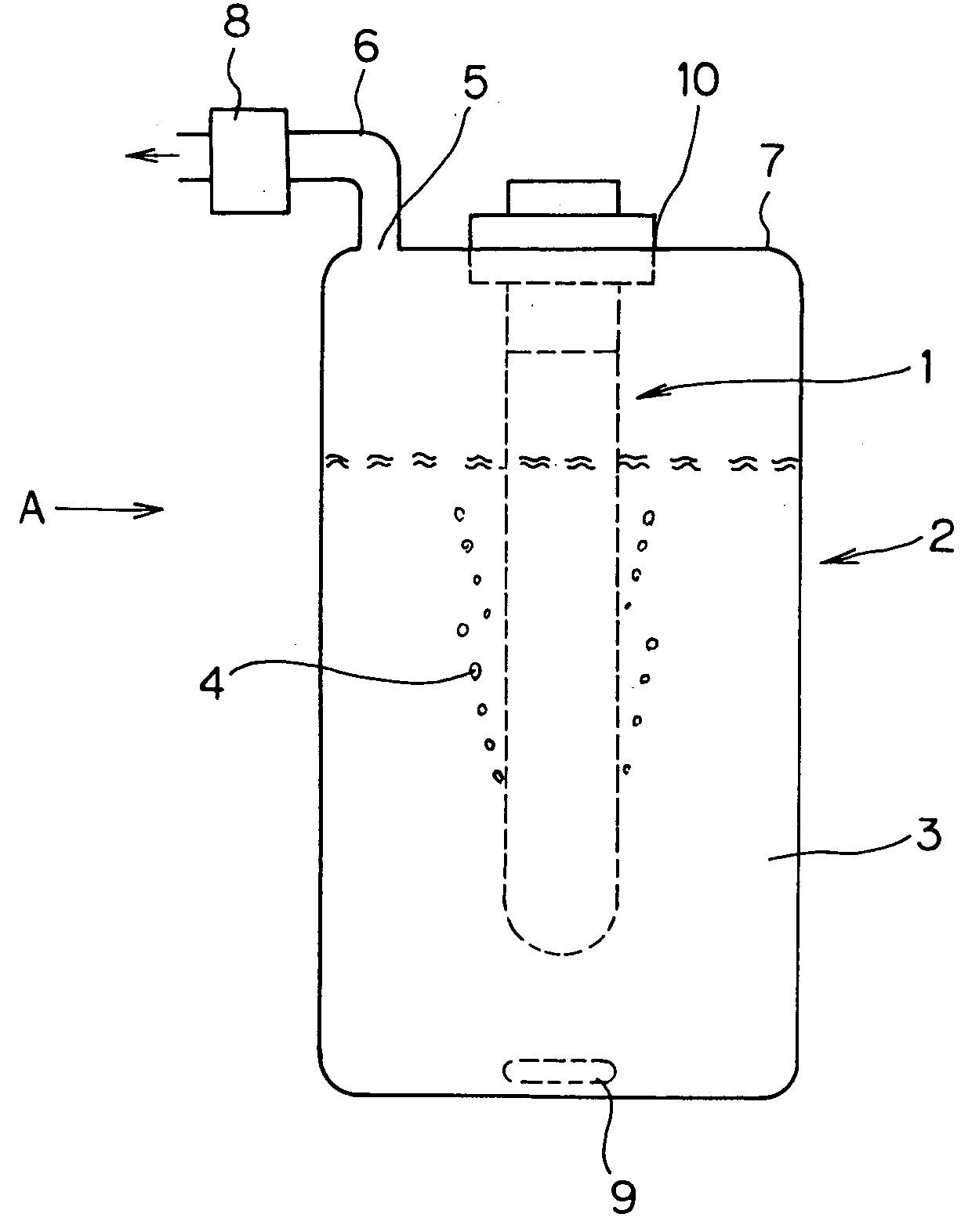

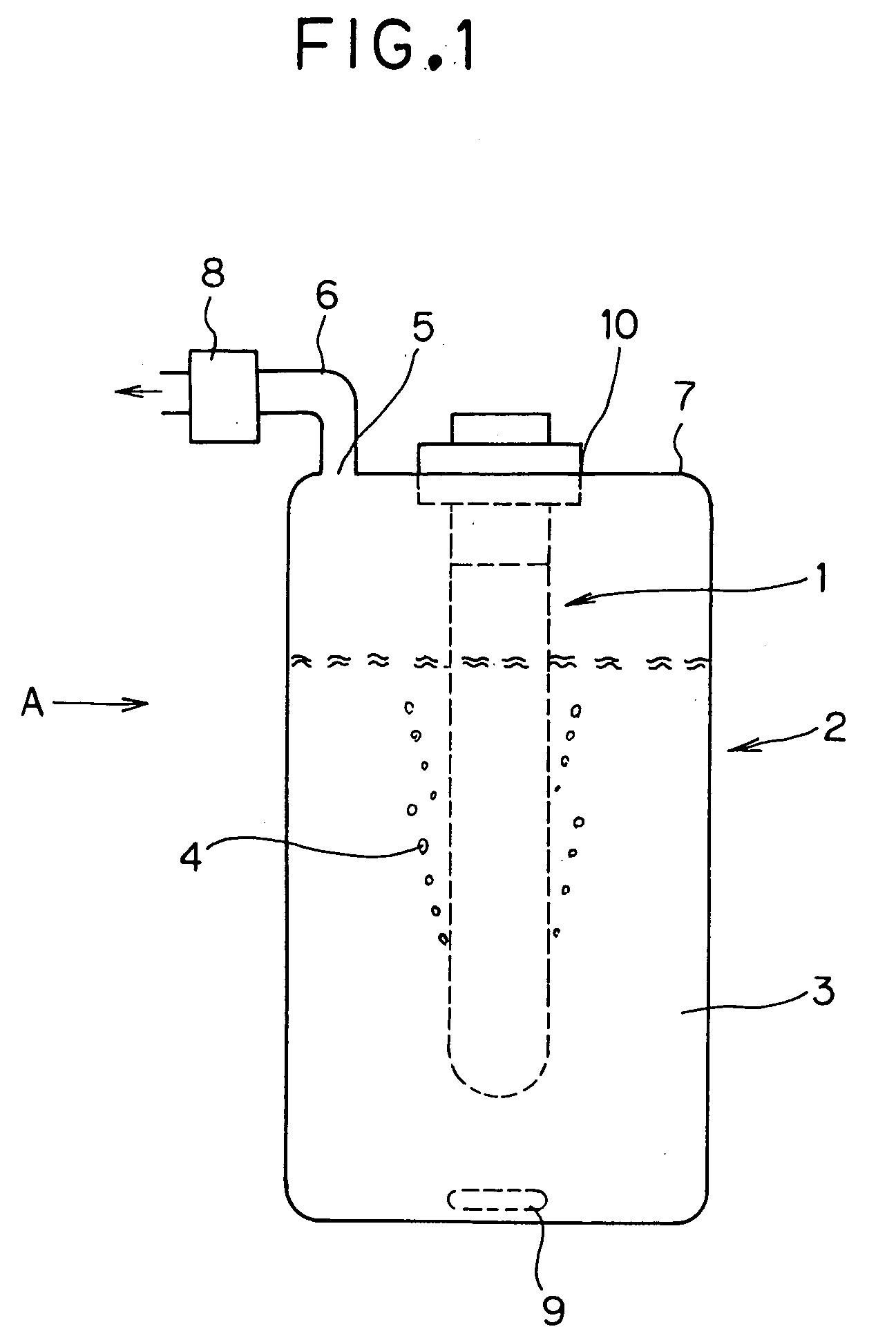

[0043] A decomposition apparatus for decomposing an organic compound in first mode of the present invention will be explained. FIG. 1 shows a schematic view illustrating a decomposition apparatus of the present invention. In FIG. 1, the decomposition apparatus A comprises an excimer lamp 1 and a decomposition container 2. The excimer lamp 1 is equipped to the decomposition container 2 to immerse in a liquid 3 of at least one selected from a liquid of an organic compound and a liquid containing an organic compound. The organic compound in liquid 3 is decomposed by emission of UV light irradiated from the excimer lamp 1.

[0044] The organic compound may suitable be selected from flon, dioxin (polychlorinated dibenzo-para-dioxin), PCB (polychlorinated biphenyl), trichloroethylene, tetrachloroethylene, dichloromethane, tetrachloromethane, 1,2-dichloroethane, 1,1-dichloroethane, cis-1,2-dichloroethane, 1,1,1-trichloroethane, 1,3-dichloropropene and the mixture thereof. All of the organic c...

second embodiment

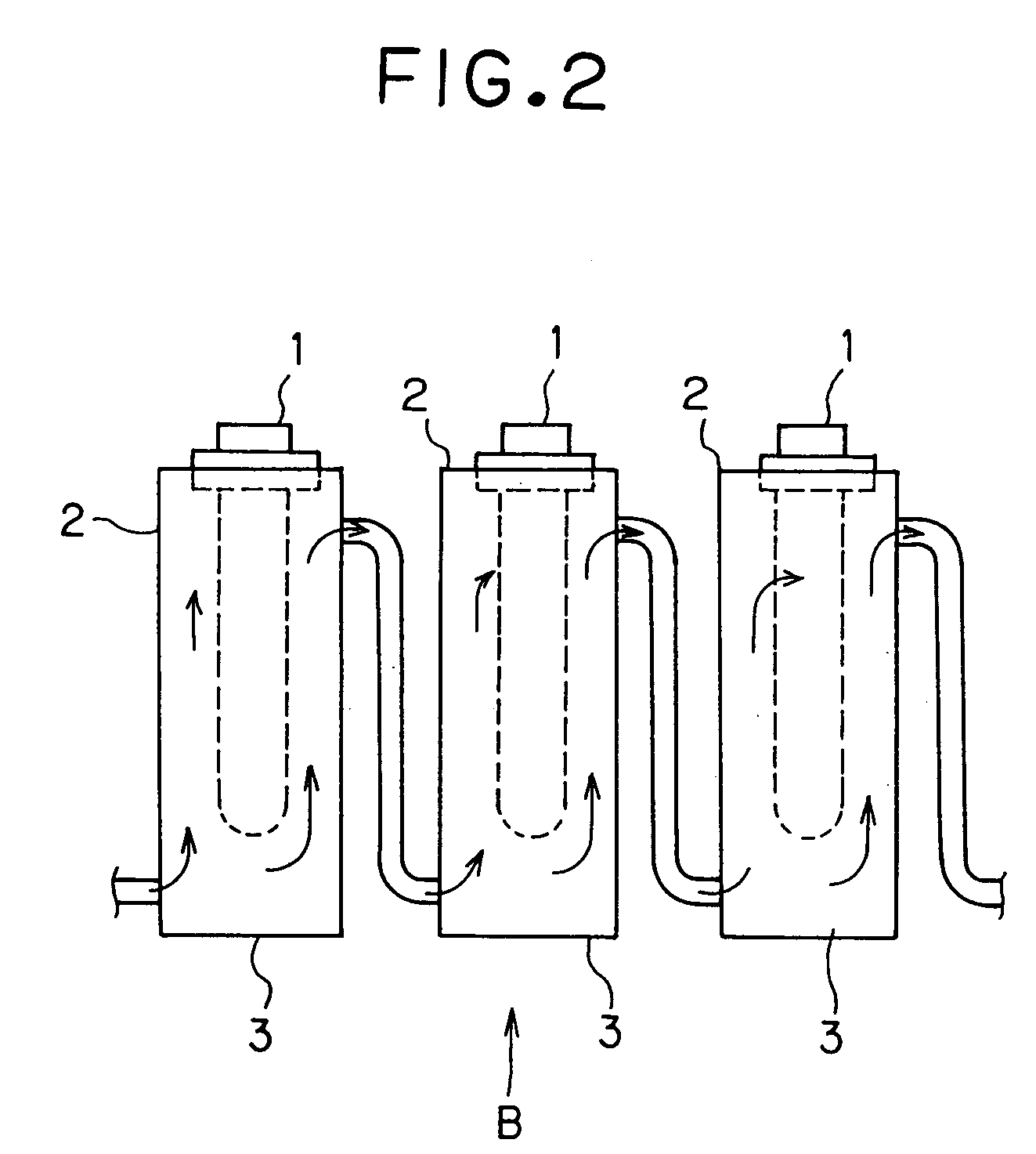

[0046]FIG. 2 shows a schematic view illustrating a decomposition apparatus (B) of the present invention. In the decomposition apparatus B as shown in FIG. 2, two or more containers 2 each having the excimer lamp 1 may be joints for flowing the fluid in one container to the other container in order. In the decomposition apparatus B, the liquid 3 is emitted by light irradiated from the excimer lamp 1 during flowing in the container 2 so that the organic compound in the liquid 3 is decomposed continuously and efficiently. According to the decomposition apparatus (B), the efficiency of decomposition and the quantity of decomposition treatment of the organic compound can be improved.

[0047]FIG. 3 shows a schematic longitudinal cross sectional view illustrating an embodiment of an excimer lamp used for the decomposition apparatus of the present invention. As shown in FIG. 1 and FIG. 2, the excimer lamp 1 is equipped to the container 2 to immerse in the liquid 3. The excimer lamp 1 comprise...

fifth embodiment

[0052]FIG. 7 shows a schematic view illustrating a decomposition apparatus E to decompose the organic compound in gas 72, which is evaporated by heat of the liquid 3, by emission of the UV light irradiated from the excimer lamp unit 71 which has excimer lamp. The kind of the heat apparatus 72, the position of the attachment thereof and the heating manner of the heat apparatus are not particularly limited. It is preferable that the excimer lamp 71 is equipped on the top plate of the container 72 to emit the gas 74 which may be either the gas of organic compound or the gas containing the organic compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wave length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com