Method and system for online condition monitoring of multistage rotary machinery

a multi-stage rotary machinery and condition monitoring technology, applied in the direction of rotary presses, printing, instruments, etc., can solve the problems of rotating errors, gear damage, vibration, gear damage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description, numerous specific details are set forth to provide a thorough understanding of the invention. However, it is understood that the invention may be practiced without these specific details. In other instances, well-known software, circuits, structures and techniques have not been described or shown in detail in order not to obscure the invention. The term “diagnostic system” is used herein to refer to any machine for processing data, including the computer systems and network arrangements described herein.

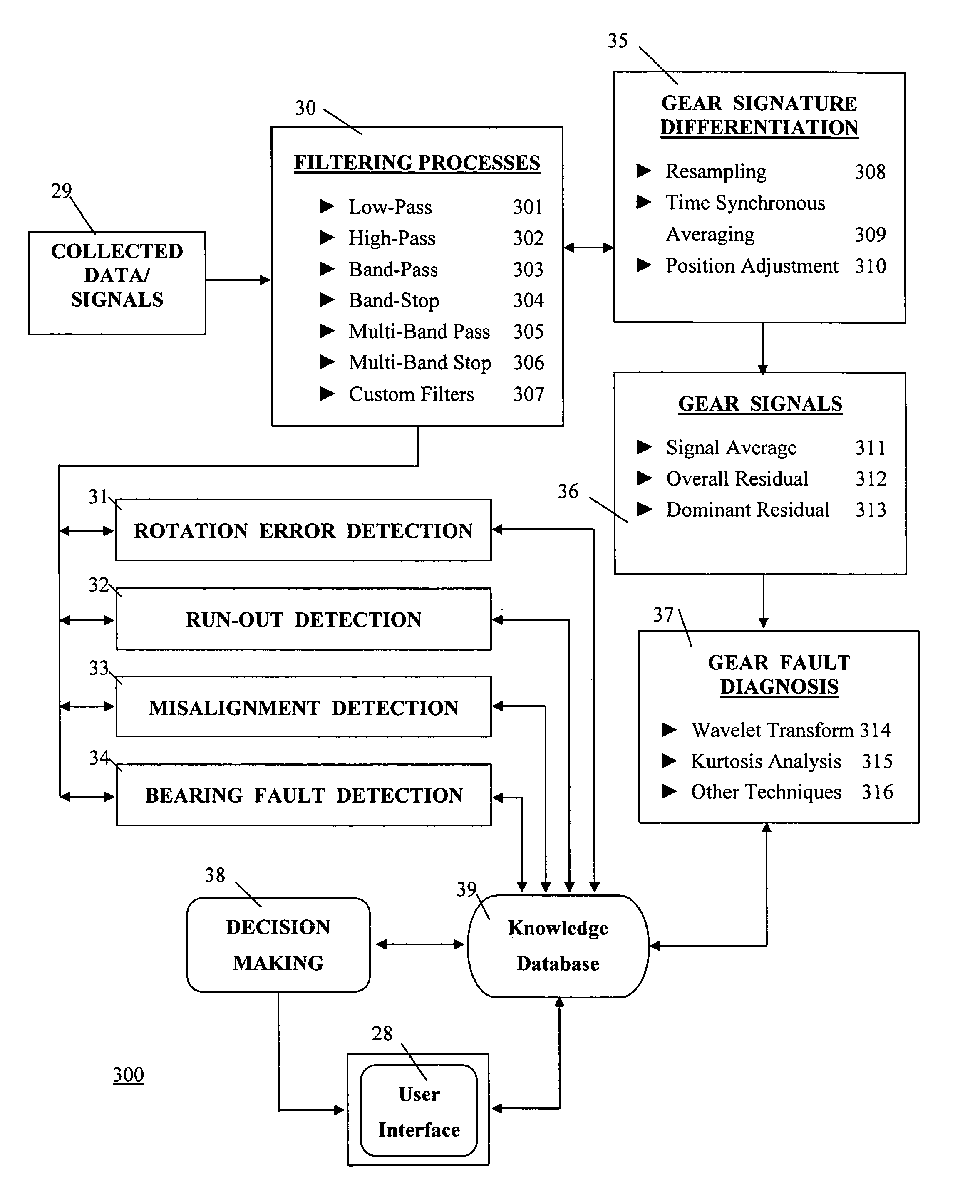

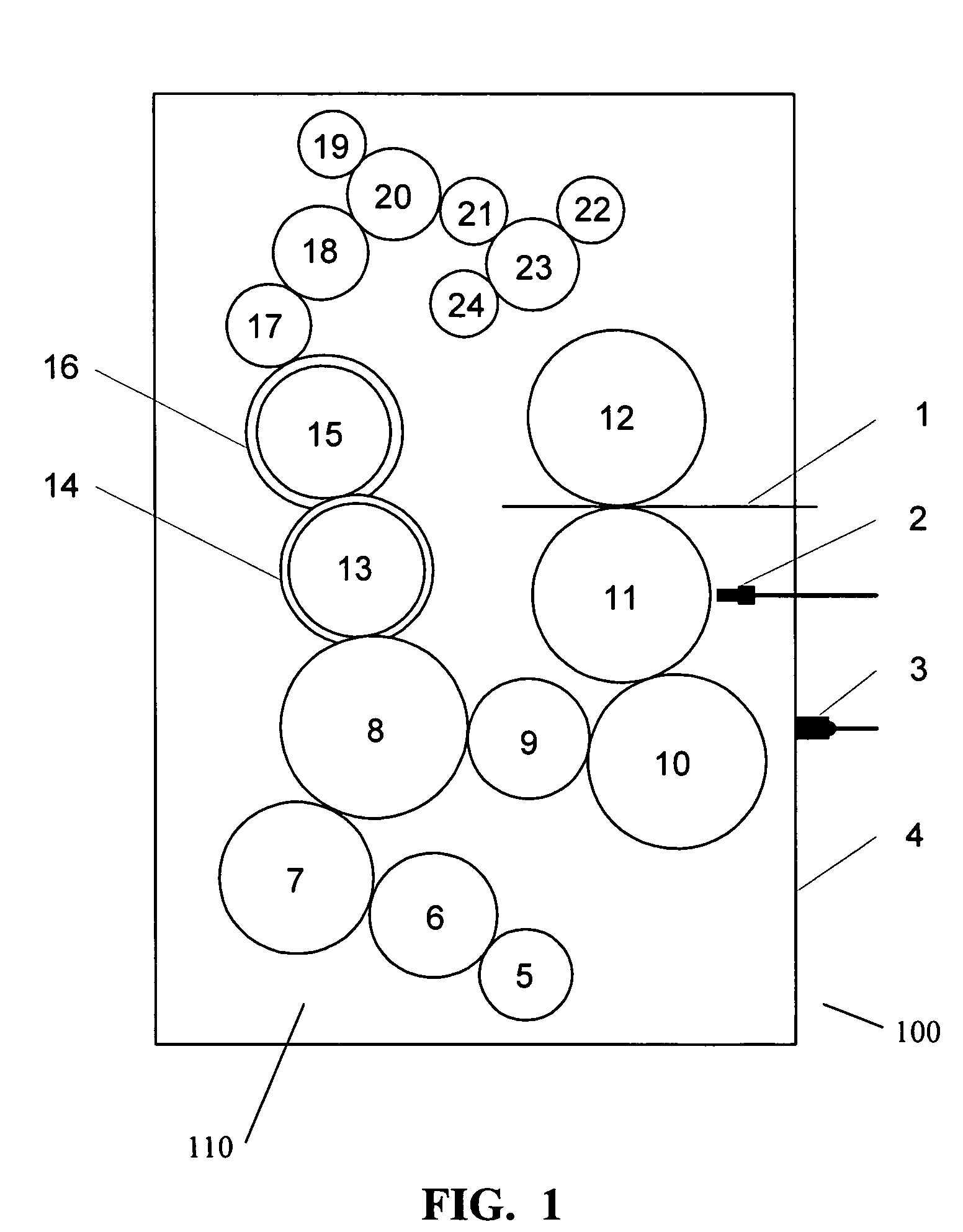

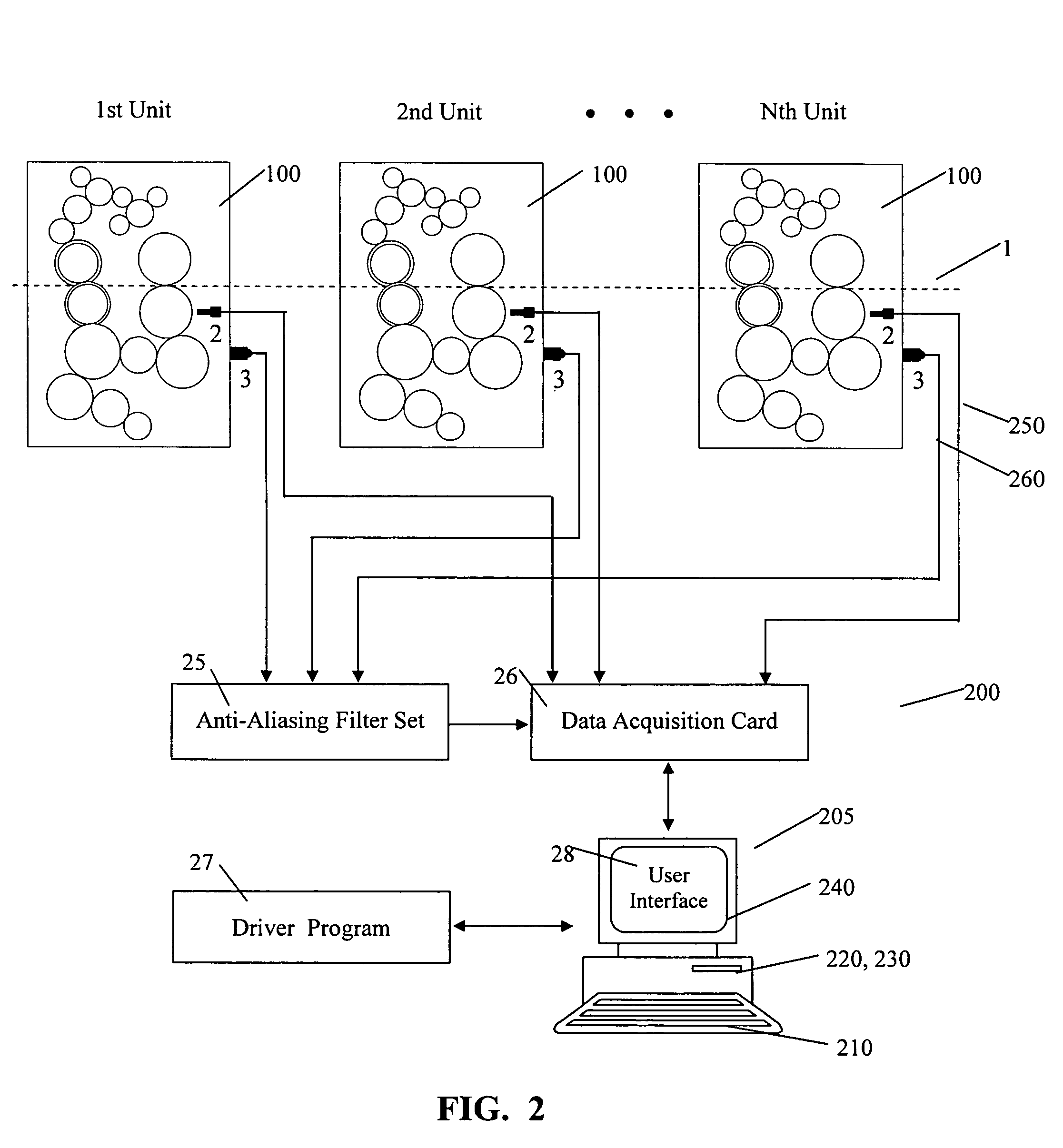

[0033] System. In general, the present invention provides a real-time diagnostic system for health condition monitoring of rotary machinery in order to facilitate predictive maintenance and repair. More particularly, the present invention provides a real-time diagnostic system for multistage rotary machinery such as printing presses to monitor rotation non-synchronization (i.e. doubling) at different stages, to isolate the sources of doubling pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com