Sub-atmospheric pressure delivery of liquids, solids and low vapor pressure gases

a technology of liquids and sub-atmospheric pressure, applied in the direction of gas/liquid distribution and storage, chemical vapor deposition coating, coating, etc., can solve the problem that the use of venturi may not be sufficient to sufficiently reduce the pressure in the system, and achieve the effect of reducing the pressure in the connecting line, reducing the pressure in the system, and reducing the inherent problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

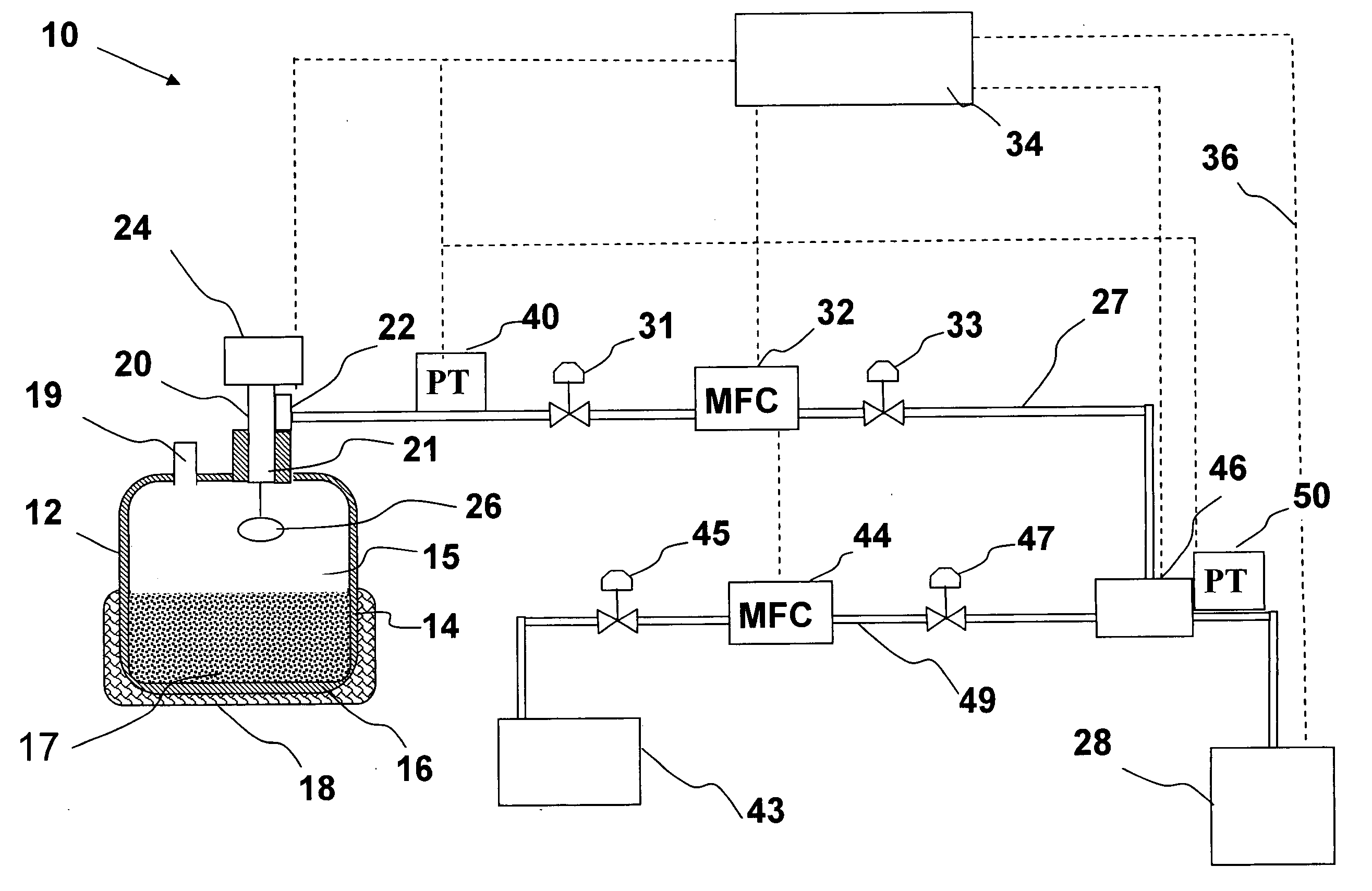

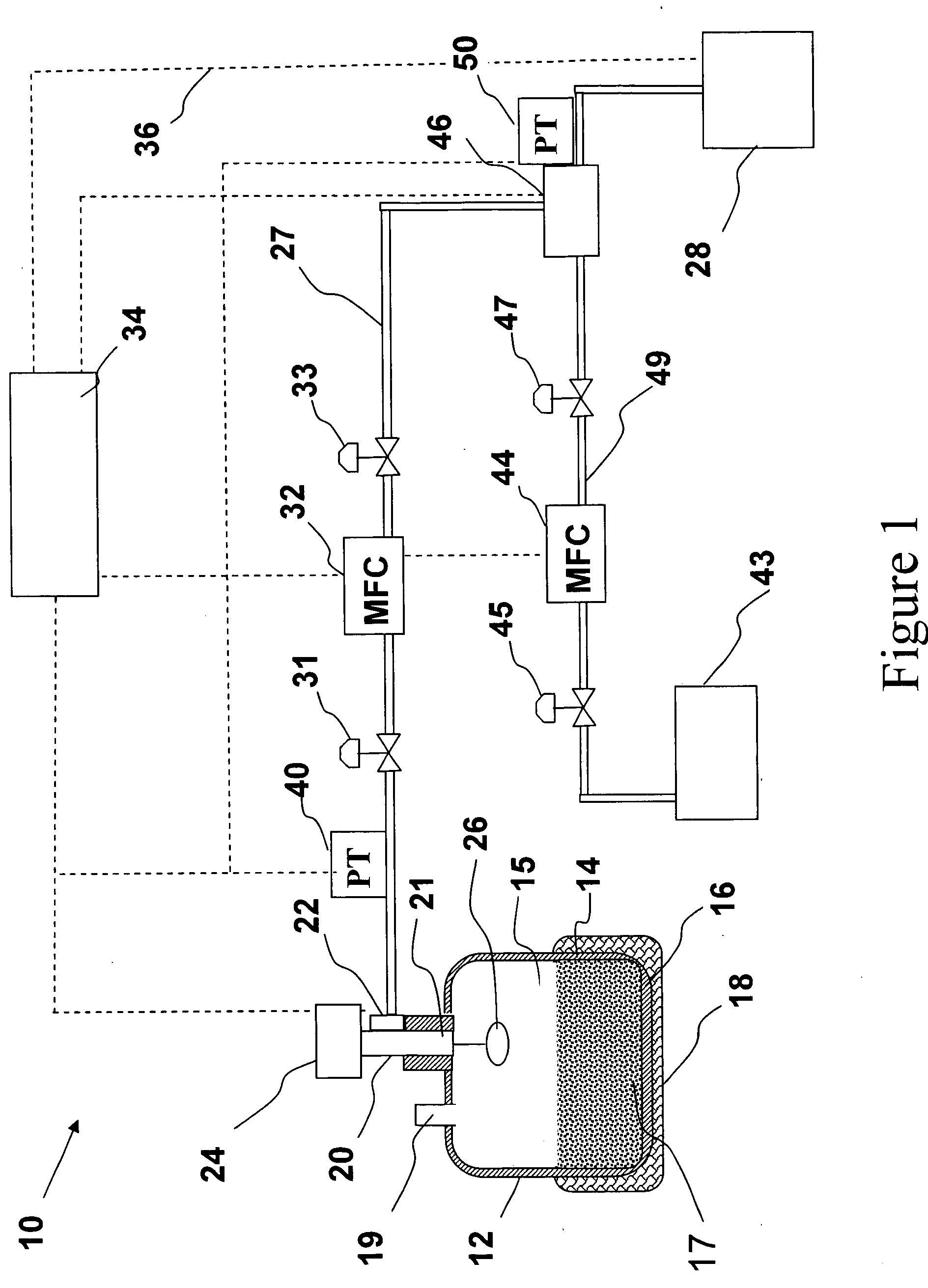

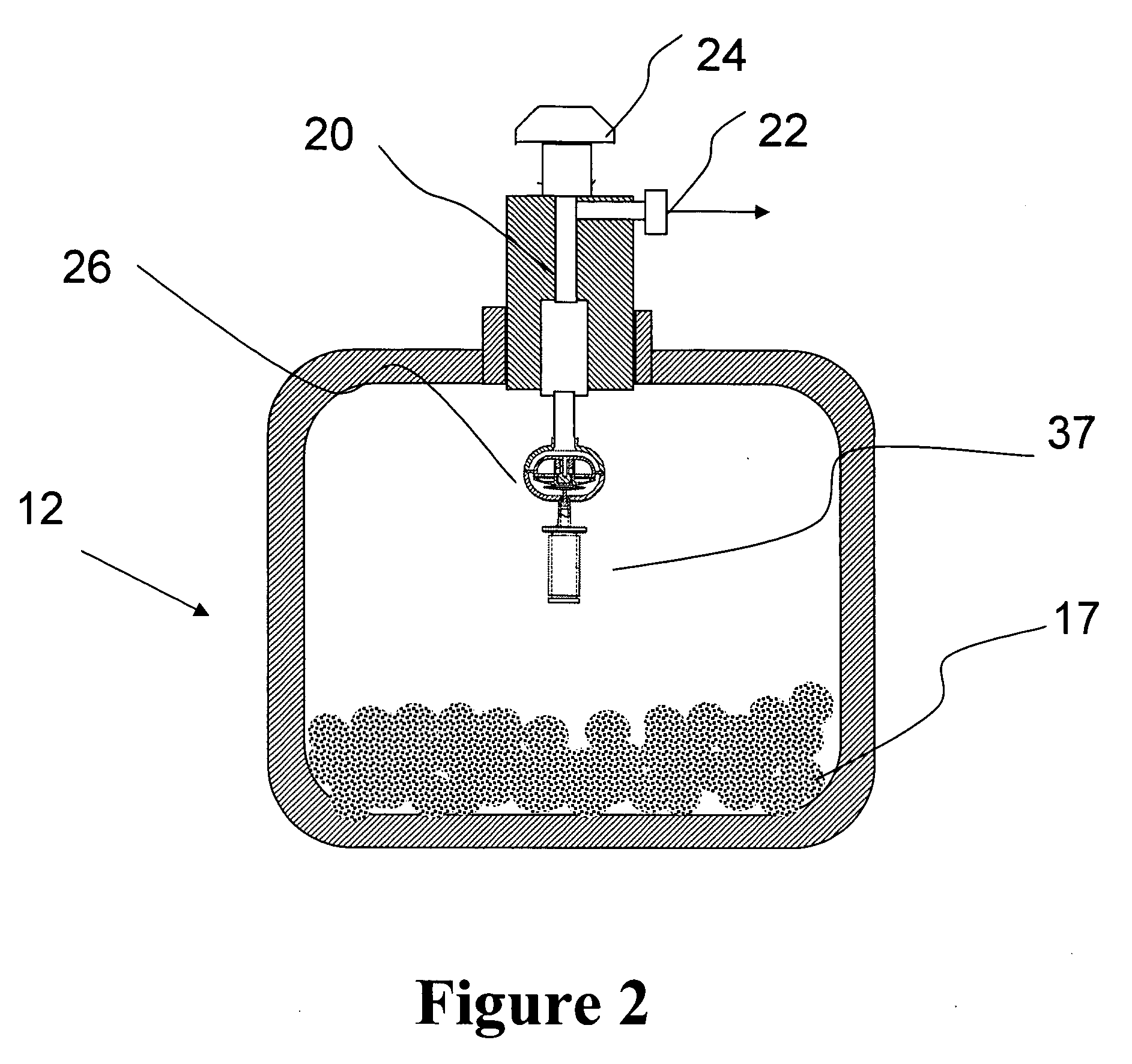

[0048] The present invention is based on the discovery that delivery of a vaporized source material to a processing tool is optimized by flowing the vaporized source material between the vaporization vessel and the processing tool through a pressure differential, wherein the pressure of the vaporized source material leaving the vaporization vessel is at a higher subatmospheric pressure value than that downstream of the vaporization vessel. If the pressure differential is sufficient the need for a carrier gas and / or trace heating connecting flow lines may be eliminated. Further, the delivery system of the present invention, operating at sub-atmospheric pressures, introduces additional safety and control advantages. As the system is operated under a vacuum, releases—should they occur—are contained within the delivery system, and as such, exposure to workers from such incidents related to loss of integrity of the flow circuit system is almost non-existent. Additionally, it is not neces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com