Calcium fortified dairy products

a calcium-fortified, dairy-based technology, applied in dairy products, milk preparation, application, etc., can solve the problems of reducing the yield of yogurt, so as to achieve the effect of reducing the cost of yogurt production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

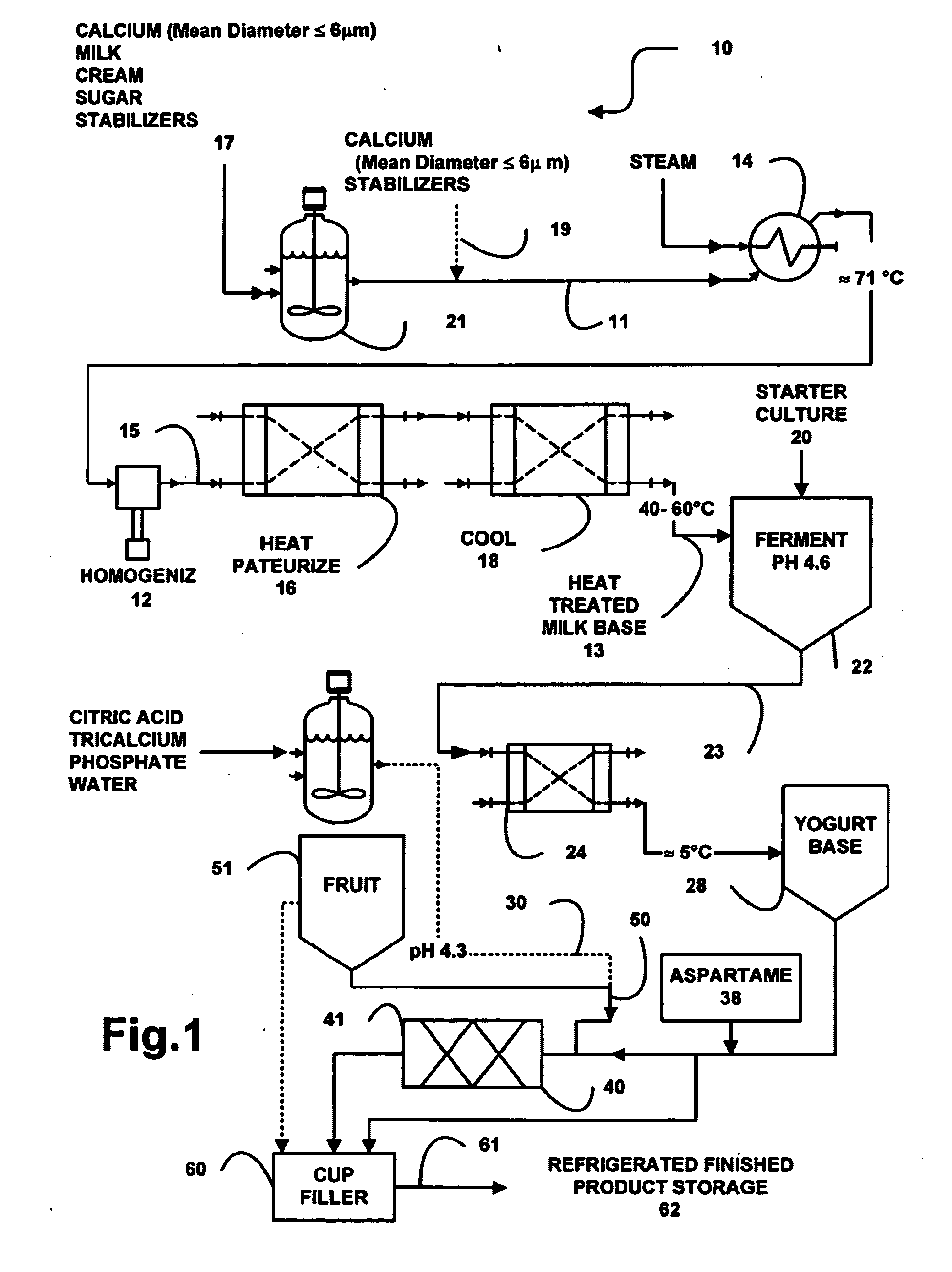

[0087] A calcium fortified stirred style yogurt of the present invention was prepared as follows:

[0088] 150 kilograms of low fat yogurt base mix was produced using whole milk, skim milk, and nonfat dry milk to make a blend with 2.8% butterfat and 13.2% milk solids non fat. To this blend was added 19.5% liquid sugar, 1.5% modified food starch, 0.5% gelatin, and 0.18% of the fine tricalcium phosphate from Godat Biochemical. Dry ingredients were incorporated with a powder funnel into a centrifugal pump to disperse the dry particulates.

[0089] A starter culture was prepared by heat treating skim milk fortified with nonfat dry milk to 12% milk solids. This mixture was held at 74° C. for 45 minutes and then cooled while agitating the mixture. When the mix was cooled to 46° C., a commercial freeze dried or frozen yogurt starter culture was added. This was allowed to mix for sufficient time to disperse the starter culture innoculum. The agitation was then turned off and the culture was all...

example 2

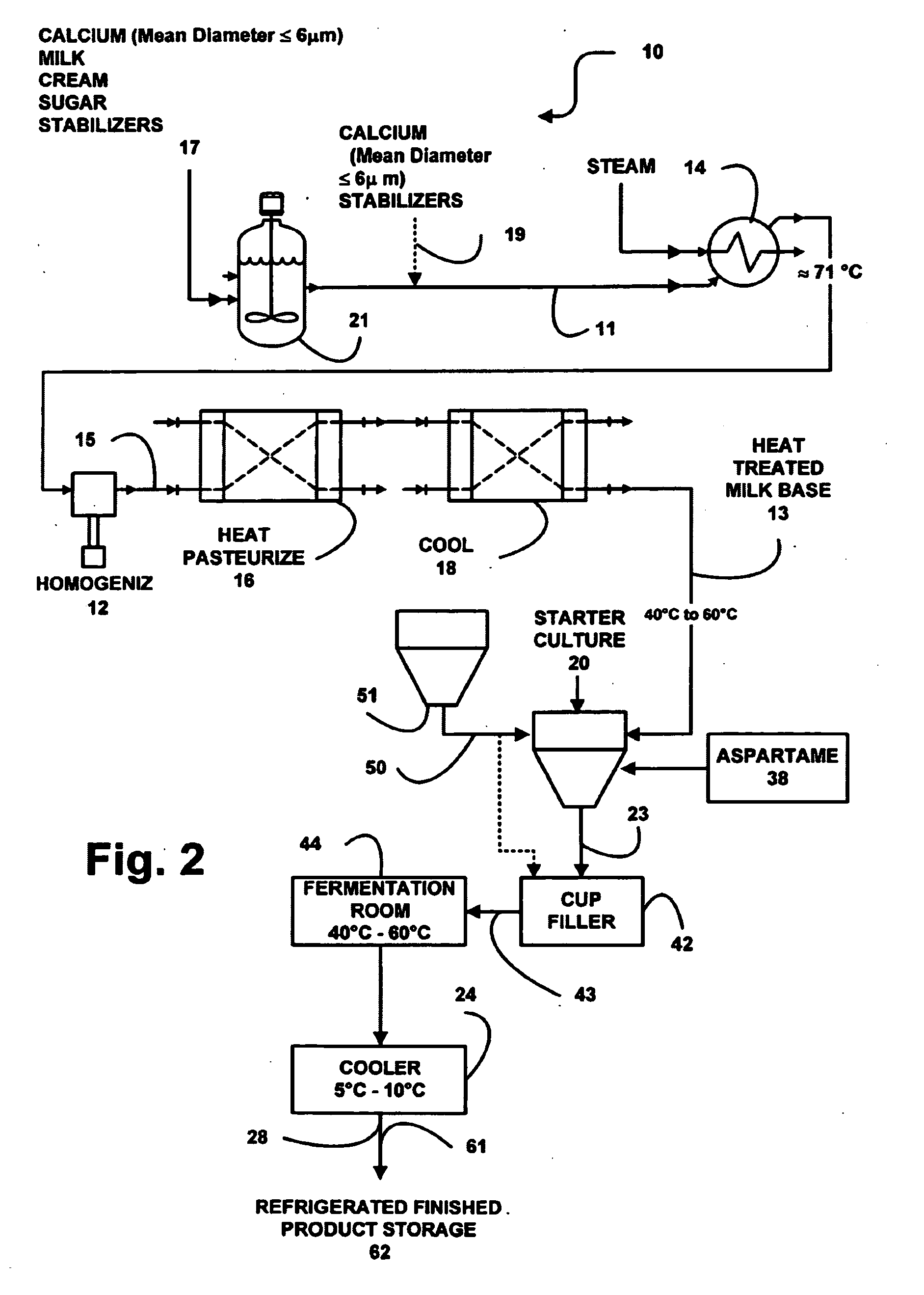

[0095] A calcium fortified cup set style yogurt product of the present invention was prepared as follows:

[0096] The inoculated yogurt base prepared as described above in Example was filled into cups and sealed prior to moving to a temperature controlled room for fermentation at 46° C. Fermentation was checked by sampling cups until a pH of 4.5 was measured which was achieved in 3.5 hours. After fermentation to desired pH, the cups were then moved to a refrigerated cooler at 4° C. and cooled rapidly to arrest fermentation to provide finished calcium fortified yogurt products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com