Sample processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

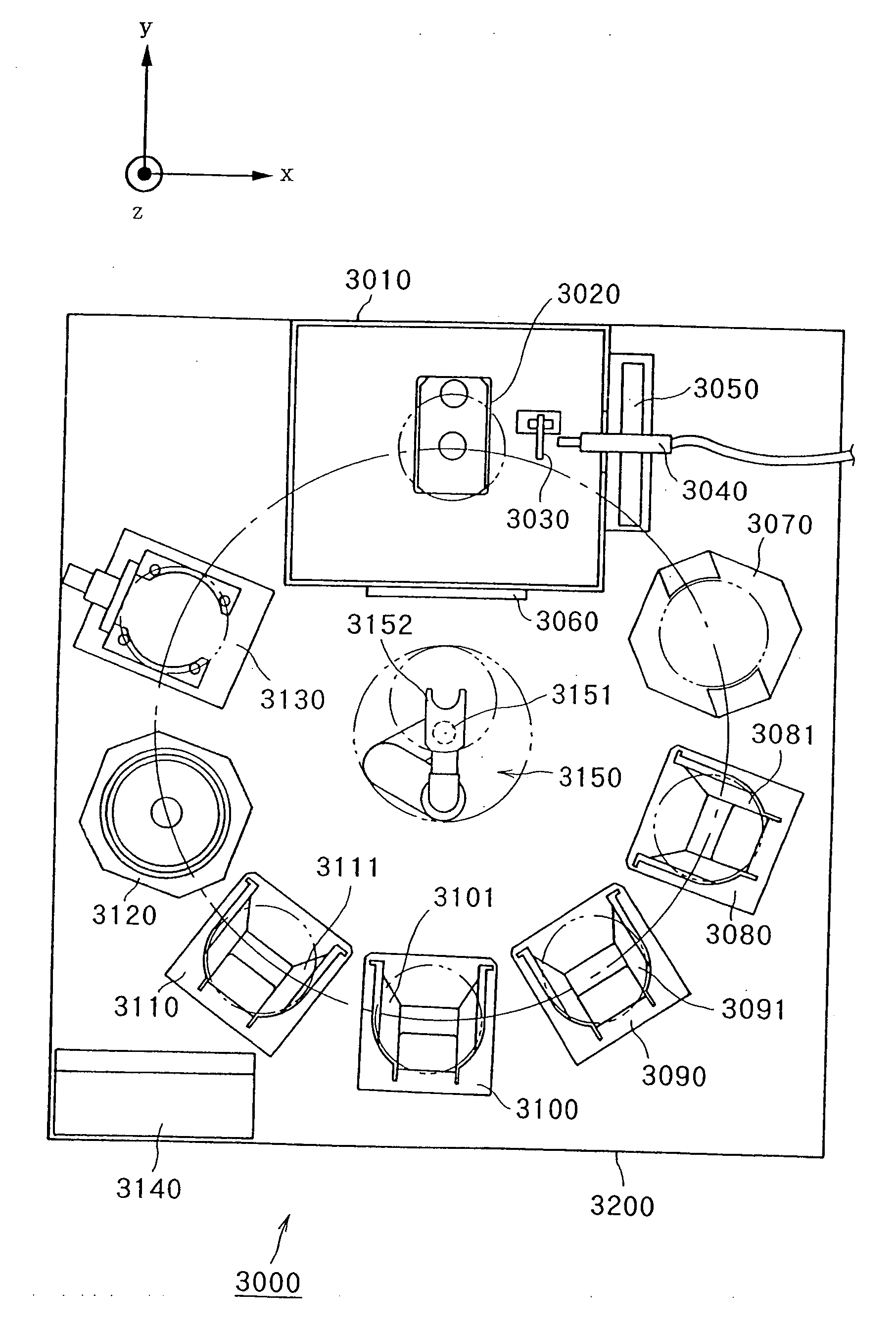

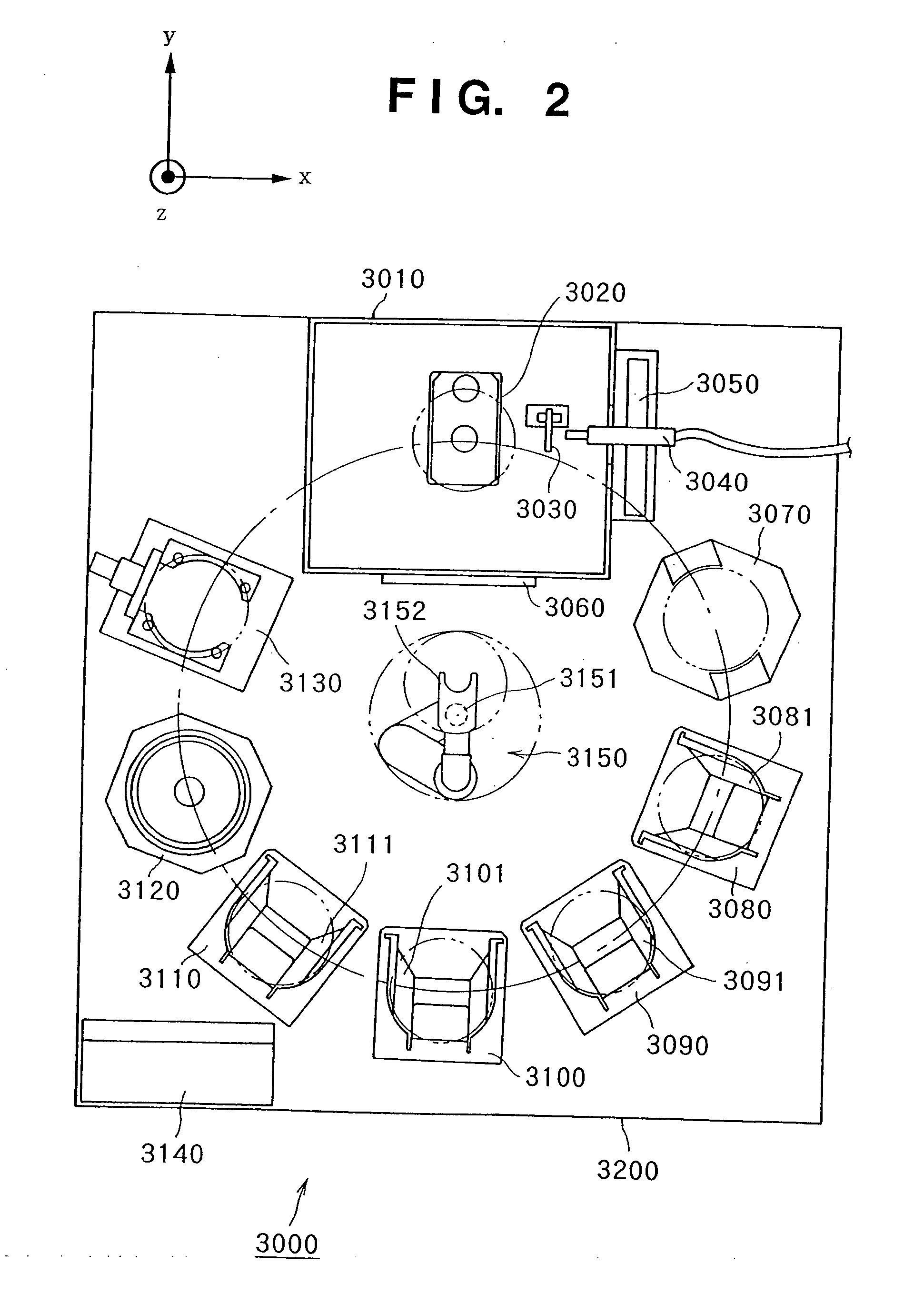

[0105]FIG. 2 is a plan view showing the schematic arrangement of a processing system according to a first embodiment of the present invention. A processing system 3000 has a scalar robot 3150 at a predetermined position (e.g., at the center) on a support table 3200 as a conveyor mechanism for a bonded substrate stack. Various processing apparatuses for handling or processing a bonded substrate stack are disposed at equidistant positions separated from a driving shaft 3151 of the scalar robot 3150. More specifically, in this embodiment, a loader 3080, centering apparatus 3070, separating apparatus 3020, inverting apparatus 3130, cleaning / drying apparatus 3120, third unloader 3110, second unloader 3100, and first unloader 3090 are disposed at equidistant positions separated from the driving shaft 3151 of the scalar robot 3150.

[0106] Before processing, a first cassette 3081 storing one or a plurality of bonded substrate stacks is placed on the loader 3080, an empty second cassette 309...

second embodiment

[0136]FIG. 14 is a plan view showing the schematic arrangement of a processing system according to the second embodiment of the present invention. In a processing system 6000, a bonded substrate stack is extracted from a cassette and separated, and separated substrates are cleaned and dried, classified, and stored in cassettes.

[0137] This processing system 6000 has, as a bonded substrate stack conveyor mechanism, a scalar robot 6150 and horizontal driving shaft 6160 for linearly driving the scalar robot 6150. In the processing system 6000, the scalar robot 6150 is linearly moved along the horizontal driving shaft 6160, and simultaneously, a robot hand 6152 of the scalar robot 6150 is pivoted about a pivot shaft 6151 in a horizontal plane to move the robot hand 6152 close to or away from the pivot shaft 6151, thereby conveying a bonded substrate stack or separated substrate among the apparatuses.

[0138] The processing system 6000 has various processing apparatuses for handling or pr...

third embodiment

[0168]FIG. 15 is a plan view showing the schematic arrangement of a processing system according to the third embodiment of the present invention. In a processing system 6500, a bonded substrate stack is extracted from a cassette and separated, and separated substrates are cleaned and dried, classified, and stored in cassettes, as in the processing system 6000 of the first embodiment. However, the processing system 6500 is different from the first embodiment in that the system has two separating apparatuses.

[0169] This processing system 6500 has, as a bonded substrate stack conveyor mechanism, a scalar robot 6150 and a horizontal driving shaft 6160 for linearly driving the scalar robot 6150. In the processing system 6500, the scalar robot 6150 is linearly moved along the horizontal driving shaft 6160, and simultaneously, a robot hand 6152 of the scalar robot 6150 is pivoted about a pivot shaft 6151 in a horizontal plane to move the robot hand 6152 close to or away from the pivot sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com