Multilayer capacitor

a multi-layer capacitor and capacitor technology, applied in the field of multi-layer capacitors, can solve the problems of difficulty in setting the esr to a value appropriate for a prescribed esl, and the difficulty of keeping voltage fluctuations within an allowable range to a rapid change of load current, etc., to achieve the effect of suppressing voltage fluctuations in the power sour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

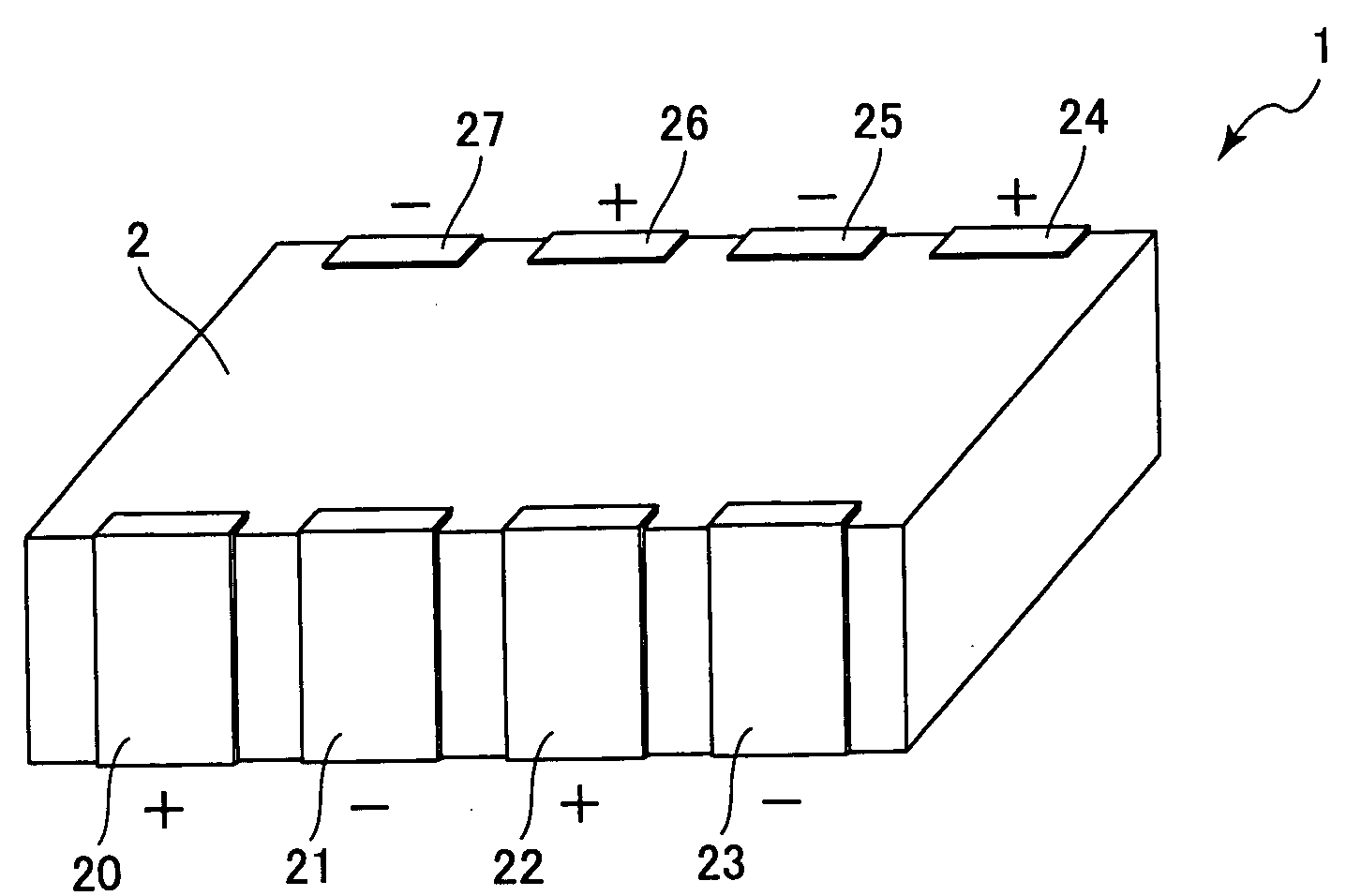

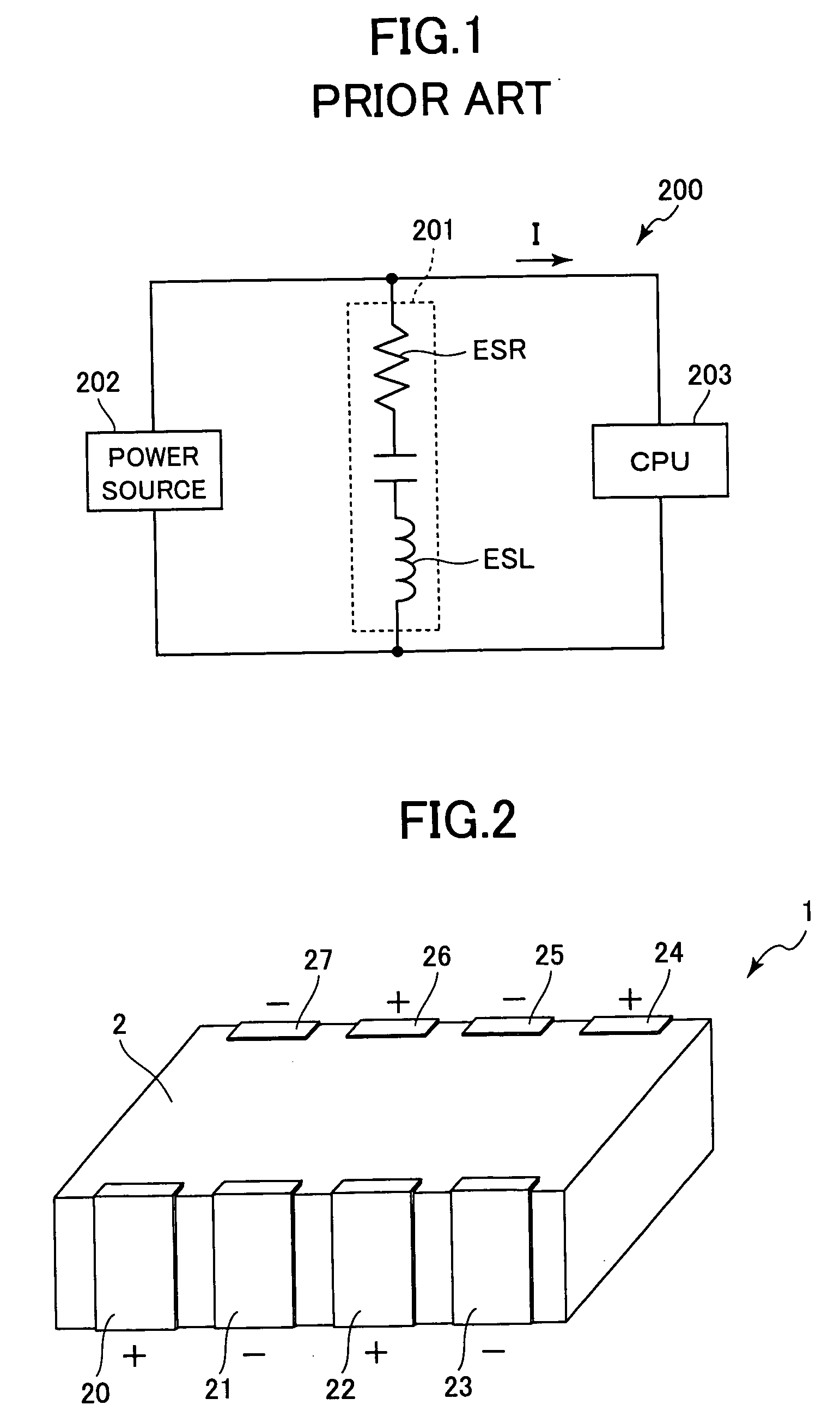

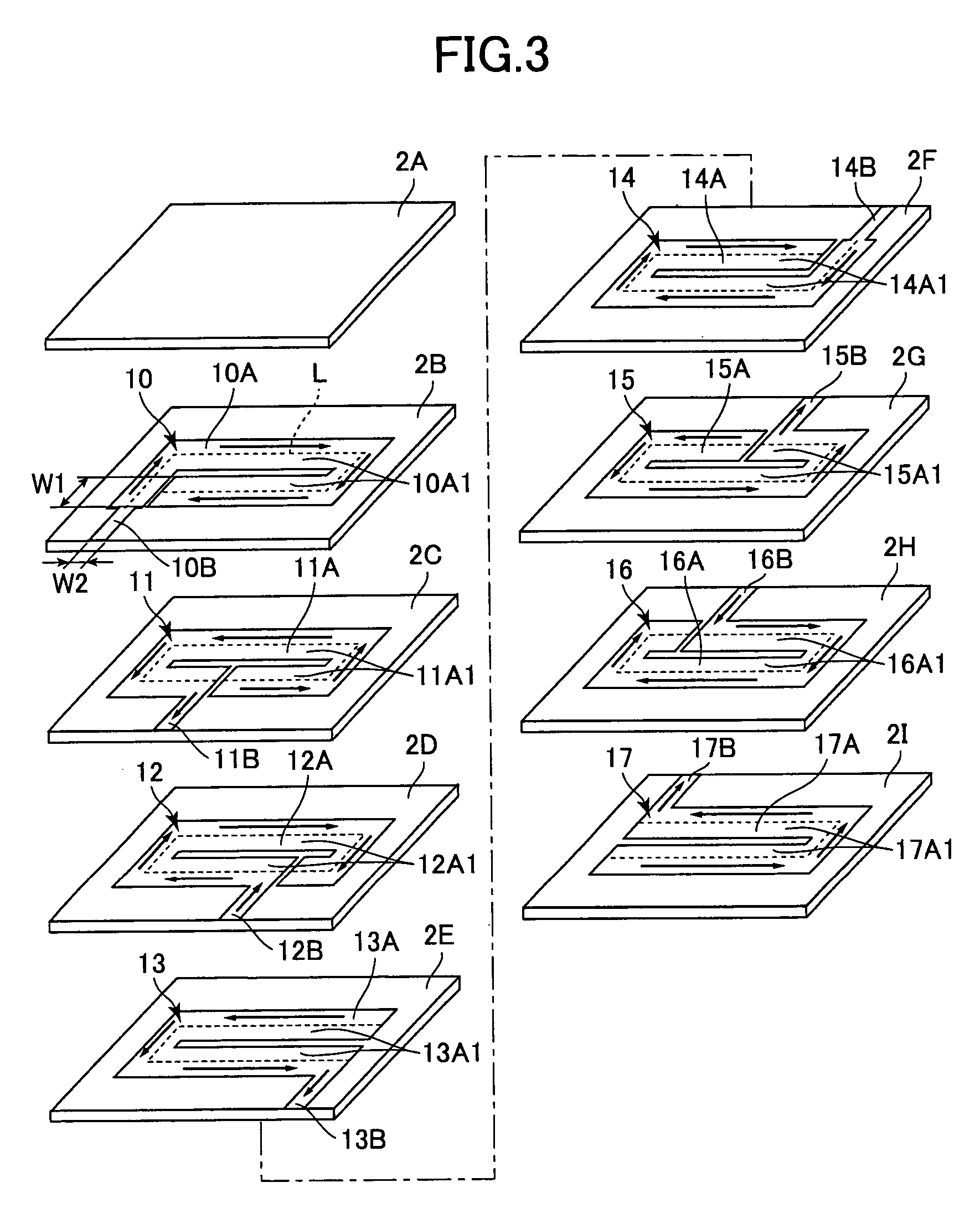

[0020] A multilayer capacitor according to the present invention will be described while referring to FIGS. 2 through 5. As shown in FIGS. 2 and 3, a multilayer capacitor 1 includes a dielectric element 2 formed of stacked sheet-like dielectric layers 2A-2I, first through eighth electrodes 10-17 disposed between adjacent dielectric layers 2A-2I, and eight external electrodes 20-27 connected to the first through eighth electrodes 10-17, respectively.

[0021] The dielectric element 2 is manufactured by sintering the dielectric layers 2A-2I which is ceramic green sheets in a stacked formation. The first through eighth electrodes 10-17 are disposed on each of the dielectric layers 2B-2I, but not on the dielectric layer 2A. The first through eighth electrodes 10-17 are formed of a base metal such as nickel or a nickel alloy, copper or a copper alloy, or a metal alloy having one of these metals as the primary component. The first through eighth electrodes 10-17 are provided with respective ...

second embodiment

[0031] Next, a multilayer capacitor according to the present invention will be described with reference to FIGS. 7 and 8.

[0032] As shown in FIGS. 7 and 8, the multilayer capacitor 101 includes a dielectric element 102 having stacked sheet-like dielectric layers 102A-102E, first through fourth electrodes 110-113 disposed between the dielectric layers 102A-102E, and four external electrodes 120-123 connected to the first through fourth electrodes 110-113, respectively. The dielectric layers 102A-102E correspond to the dielectric layers 2A, 2B, 2E, 2F, and 2I of the first embodiment, and the first through fourth electrodes 110-113 correspond to the first, fourth, fifth, and eighth electrodes 10, 13, 14, and 17 of the first embodiment. Further, the external electrodes 120-123 correspond to the external electrodes 20, 23, 24, and 27 of the first embodiment.

[0033] The dielectric element 102 is manufactured in the same way as the dielectric element 2 according to the first embodiment. Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width W1 | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com