Platinum surface coating and method for manufacturing the same

a technology of surface coating and plating process, which is applied in the direction of transportation and packaging, chemistry apparatus and processes, and other domestic objects, can solve the problems of weak structural and physical strength of platinum black, degrading the electrode and damaging the tissue, and inefficient electrical charge transfer, etc., to achieve sufficient physical and structural strength, increase the surface area, and the effect of transferring charg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

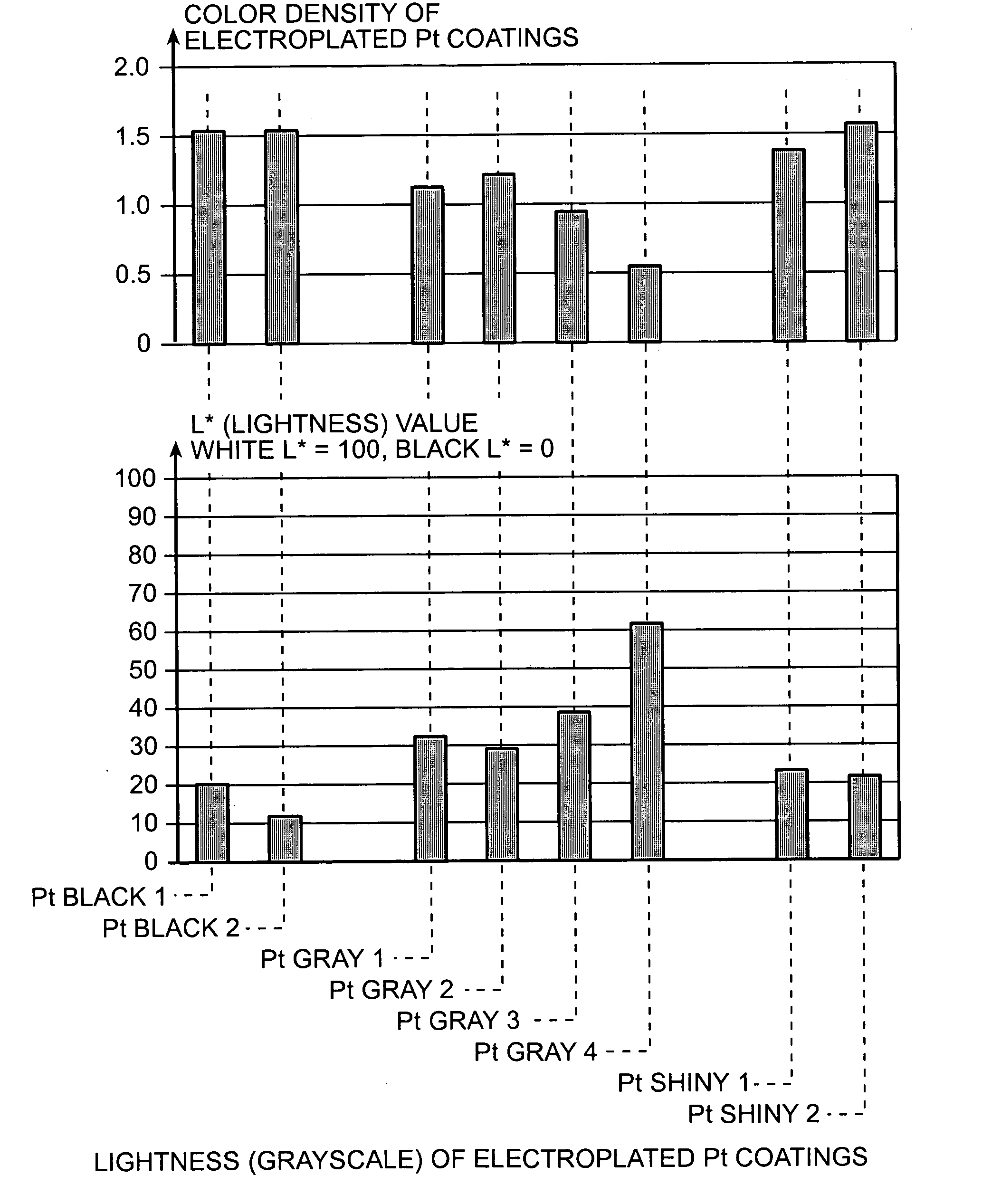

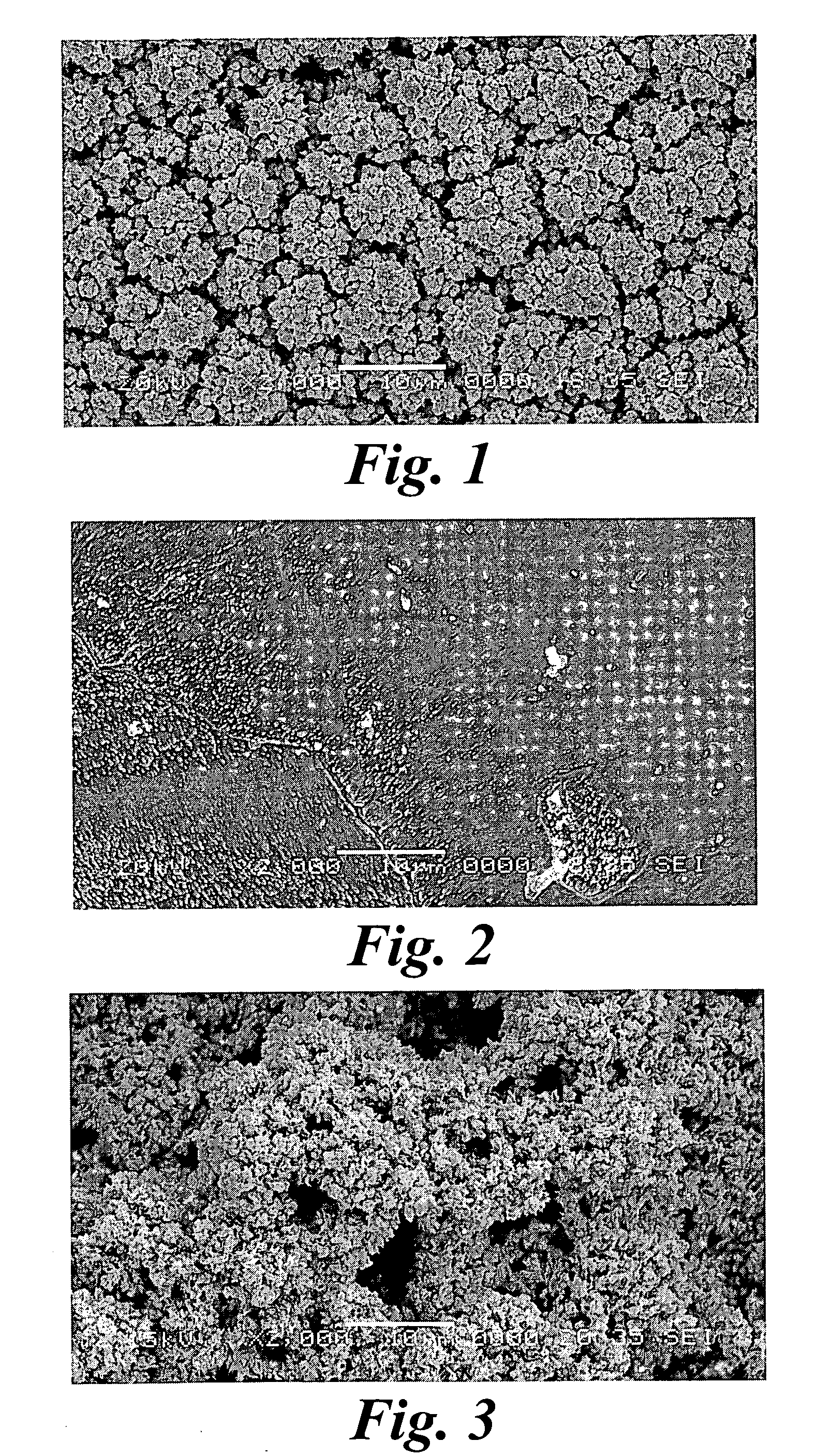

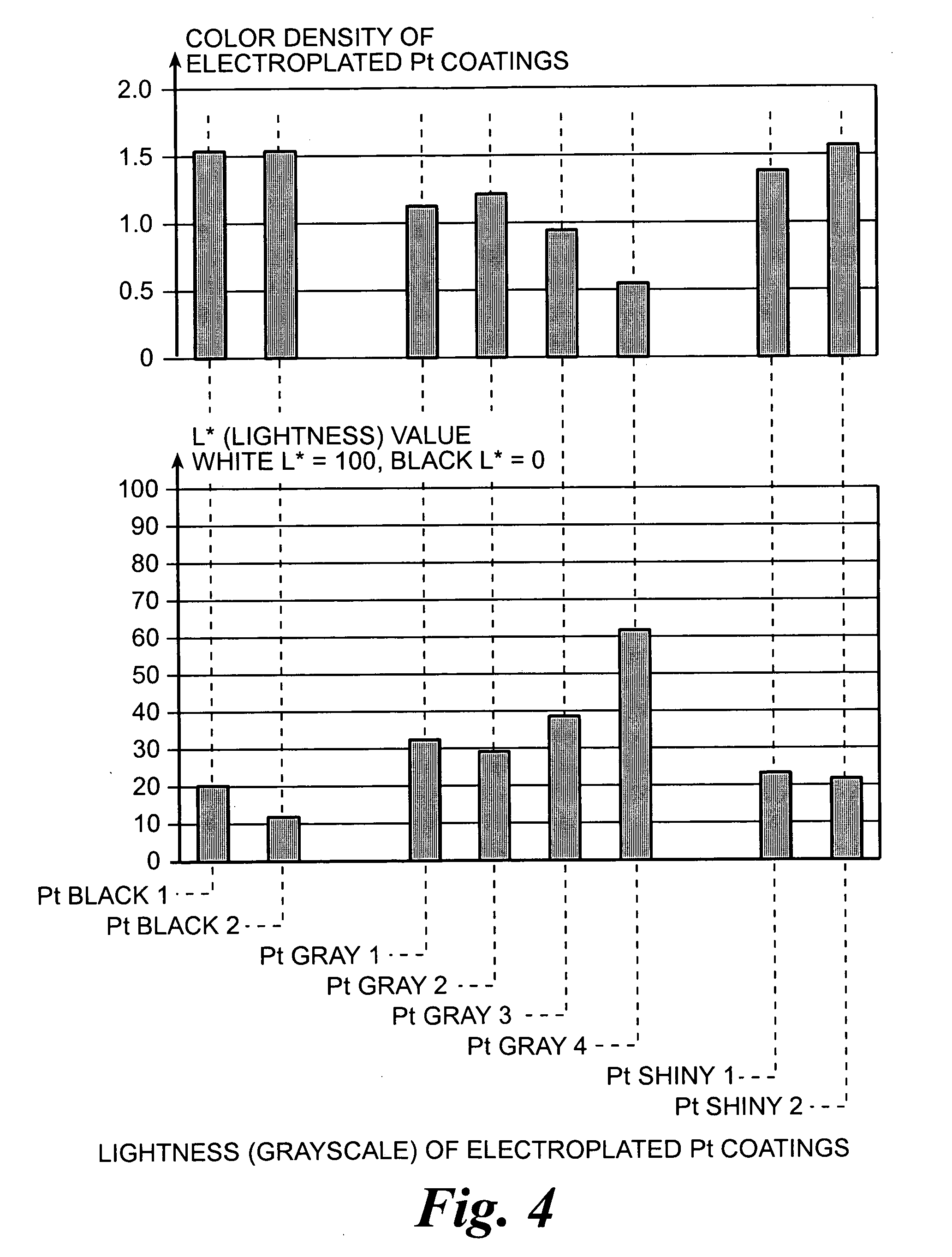

[0028] Referring to FIG. 1, an illustrative example of a platinum gray surface coating for an electrode is shown having a fractal surface with a surface area increase of greater than 5 times the surface area for a shiny platinum surface of the same geometry, shown in FIG. 2, and an increase in strength over a platinum black surface, shown in FIG. 3. FIGS. 1, 2, and 3 are images produced on a Scanning Electron Microscope (SEM) at 2000× magnifications taken by a JEOL JSM5910 microscope (Tokyo, Japan). Under this magnification level it is observed that platinum gray is of a fractal configuration having a cauliflower shape with particle sizes ranging from 0.5 to 15 microns. Each branch of such structure is further covered by smaller and smaller particles of similar shape. The smallest particles on the surface layer may be in the nanometer range. This rough and porous fractal structure increases the electrochemically active surface area of the platinum surface when compared to an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com