Knotless suture lock apparatus and method for securing tissue

a technology of suture lock and clamping device, which is applied in the field of clamping device and attaching soft tissue, can solve the problems of increasing the common problem of tendons, pain and loss of the ability to elevate and externally rotate the arm, residual weakness, etc., and achieves the effect of reducing the overall dimension of the lock in one embodiment and strong material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

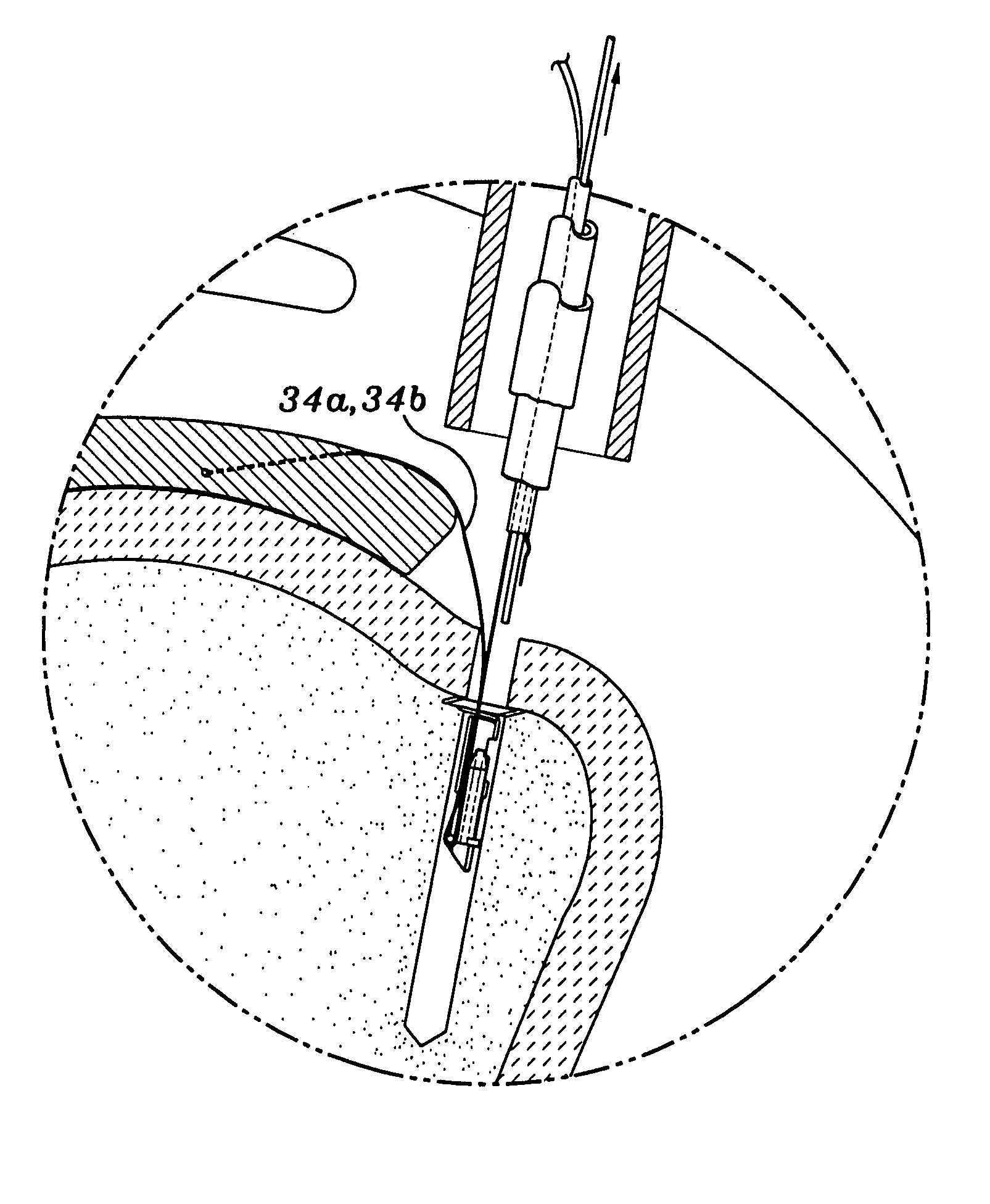

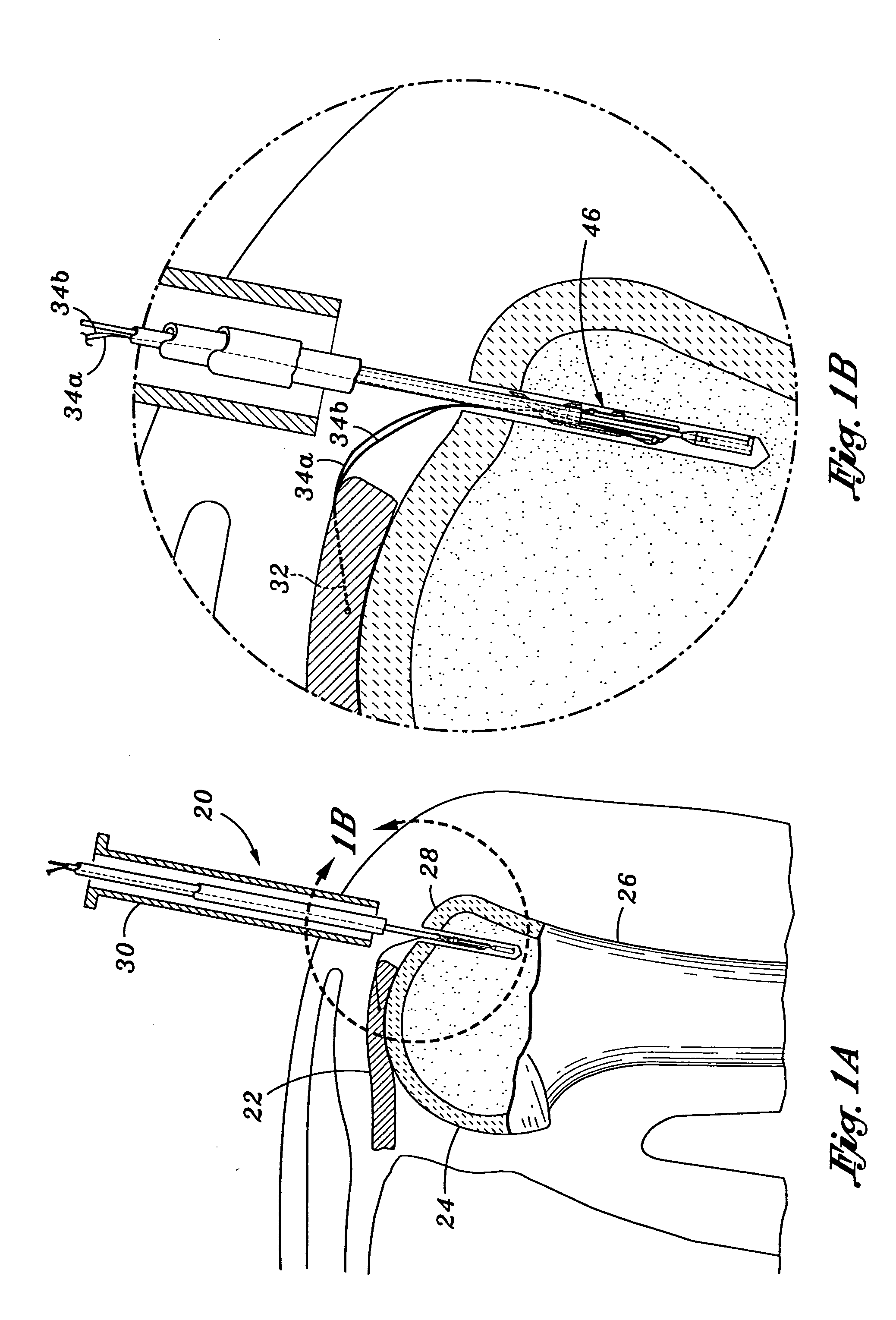

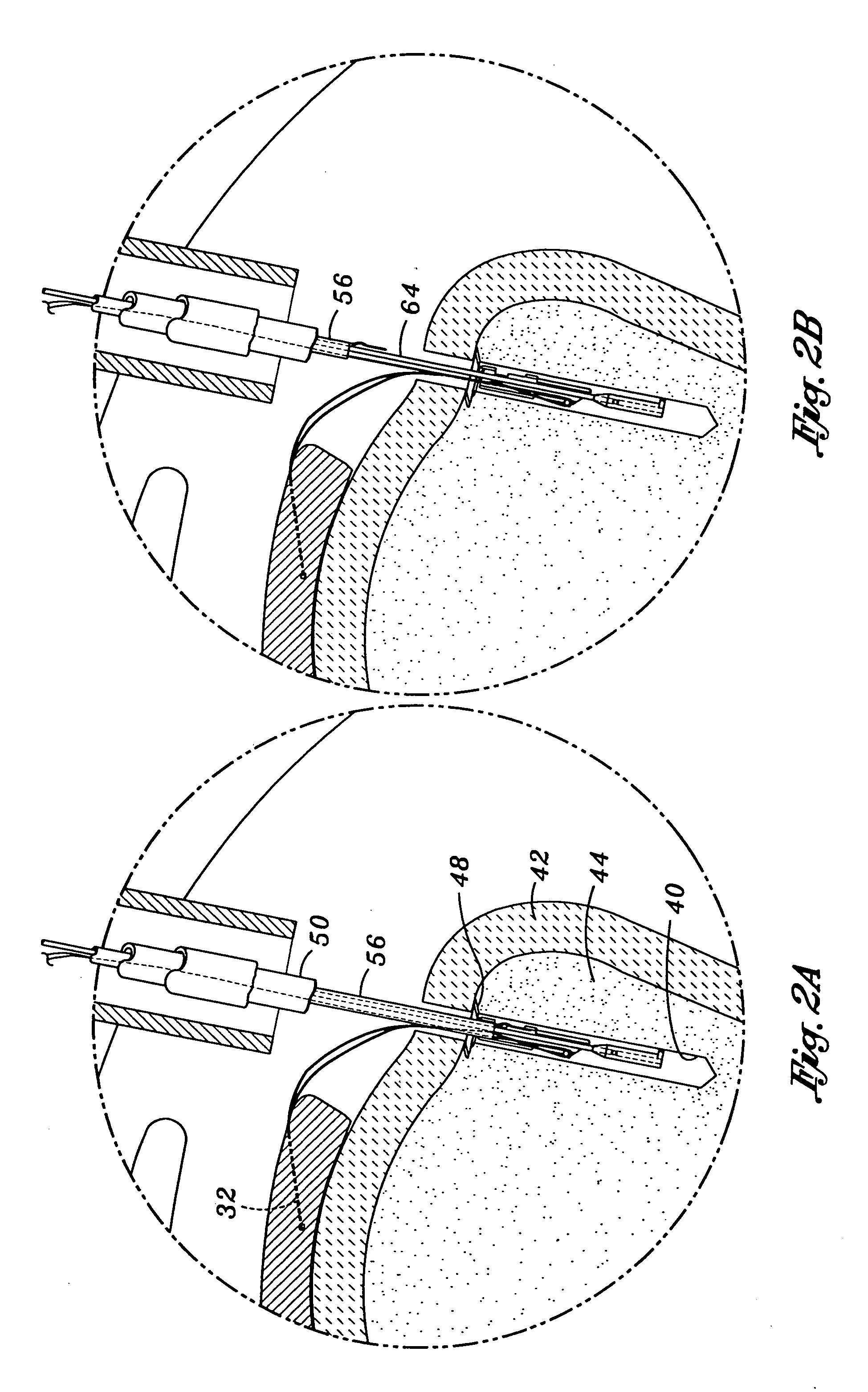

[0061] The present invention provides an improved knotless suture anchor apparatus for anchoring a length of suture with respect to a body cavity. In the exemplary embodiment described herein, the apparatus is used to anchor a length of suture to a bone structure, specifically the humeral bone of the human shoulder. The length of suture is desirably looped through soft tissue, such as a rotator cuff tendon, to approximate and fix the soft tissue with respect to the body cavity (e.g., bone structure). It should be understood, however, that the suture anchor apparatus may be utilized to secure a length of suture to body cavities other than in a bone structure, and may even be used to anchor the suture outside of a body cavity, merely to a predetermined location within the body. In this regard, the preferred apparatus includes an anchor body member within which the length of suture may be anchored without knots. If the anchor body is to be implanted within the body cavity, structure on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com