Environmental-friendly decorative stone material and manufacturing process thereof

A production process and stone technology, which is applied in the field of building decoration materials, can solve the problems of fading, failure to achieve the natural pattern and line effect of natural stone, and non-wear resistance, and achieve the effect of simple production process, novel and bright appearance, and compensation for non-moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

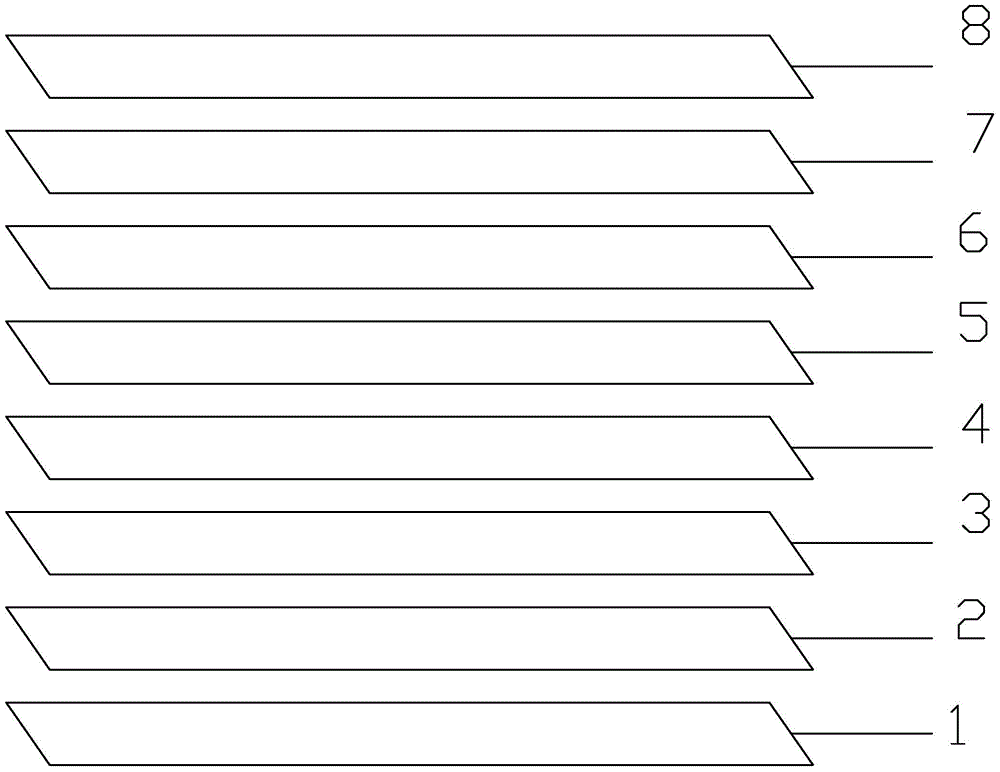

[0026] Such as figure 1 As shown, the environmentally friendly decorative stone includes stone 1, and the upper surface of the stone is successively coated with an unsaturated polyester resin putty layer 2, a synthetic resin paint primer layer 3, a printing layer or a paste layer or a synthetic resin paint color varnish. Layer 4, synthetic resin varnish layer 5;

[0027] A PVB polyvinyl butyral or synthetic resin layer 5 is arranged on the synthetic resin varnish layer, and a glass layer 7 is arranged on the PVB polyvinyl butyral or synthetic resin layer.

[0028] The sticker layer is pasted with wood veneer or bamboo veneer or pasted with paper or pasted with cloth or pasted with herbaceous plant weaving or pasted with metal or pasted with plastic or pasted with synthetic resin.

[0029] The stone is marble or granite or limestone or slate or artificial synthetic stone or tiles.

[0030] The synthetic resin paint is water-based paint.

[0031] After the glass is pasted, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com