Refrigerant system with tandem compressors and reheat function

a technology of refrigerant system and compressor, which is applied in the field of refrigerant cycle, can solve the problems that refrigerant cycle with tandem compressors has not had as complete control over temperature and humidity levels, and the reheat coil has not been utilized in a combination with tandem compressors, so as to achieve greater capacity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

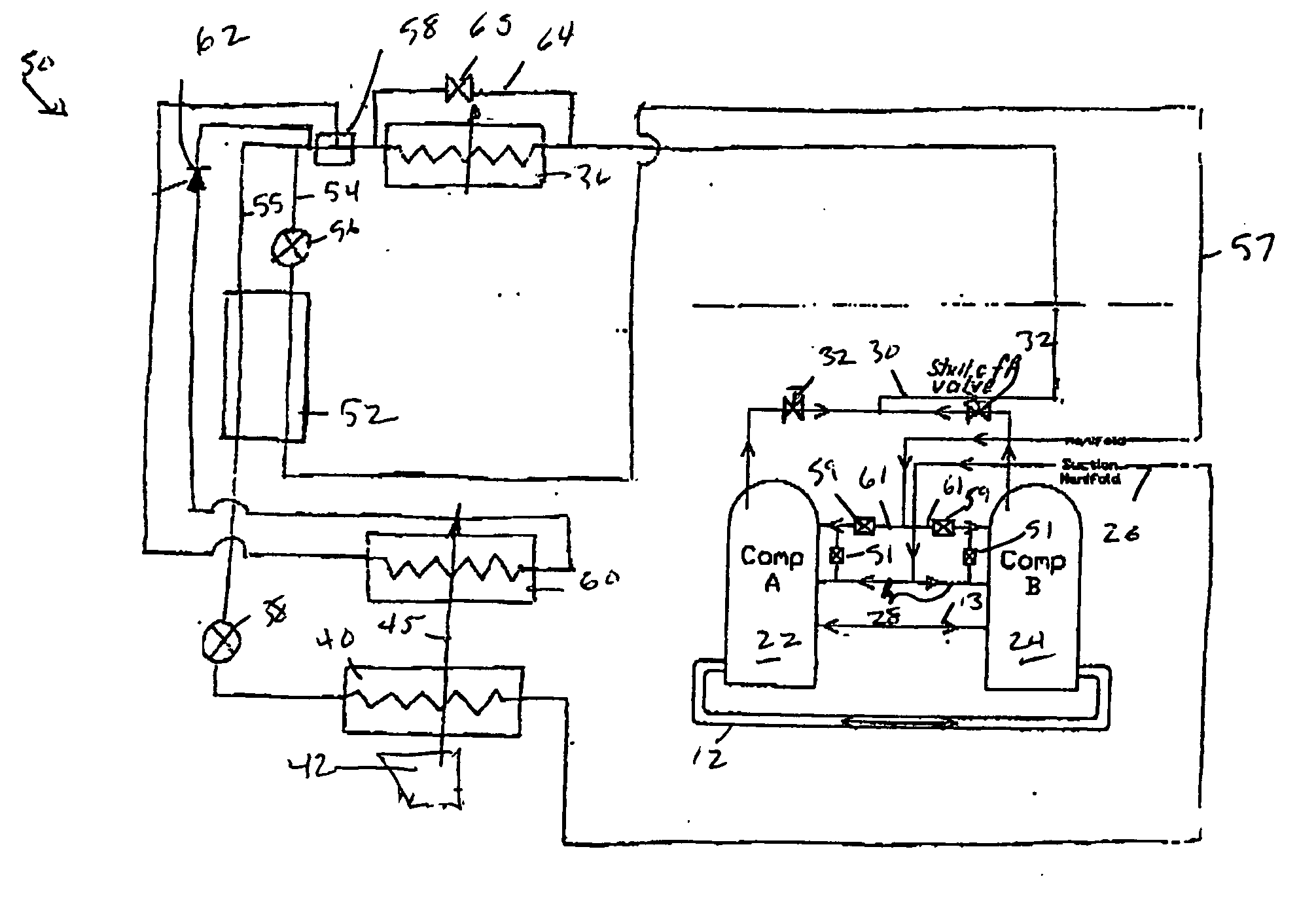

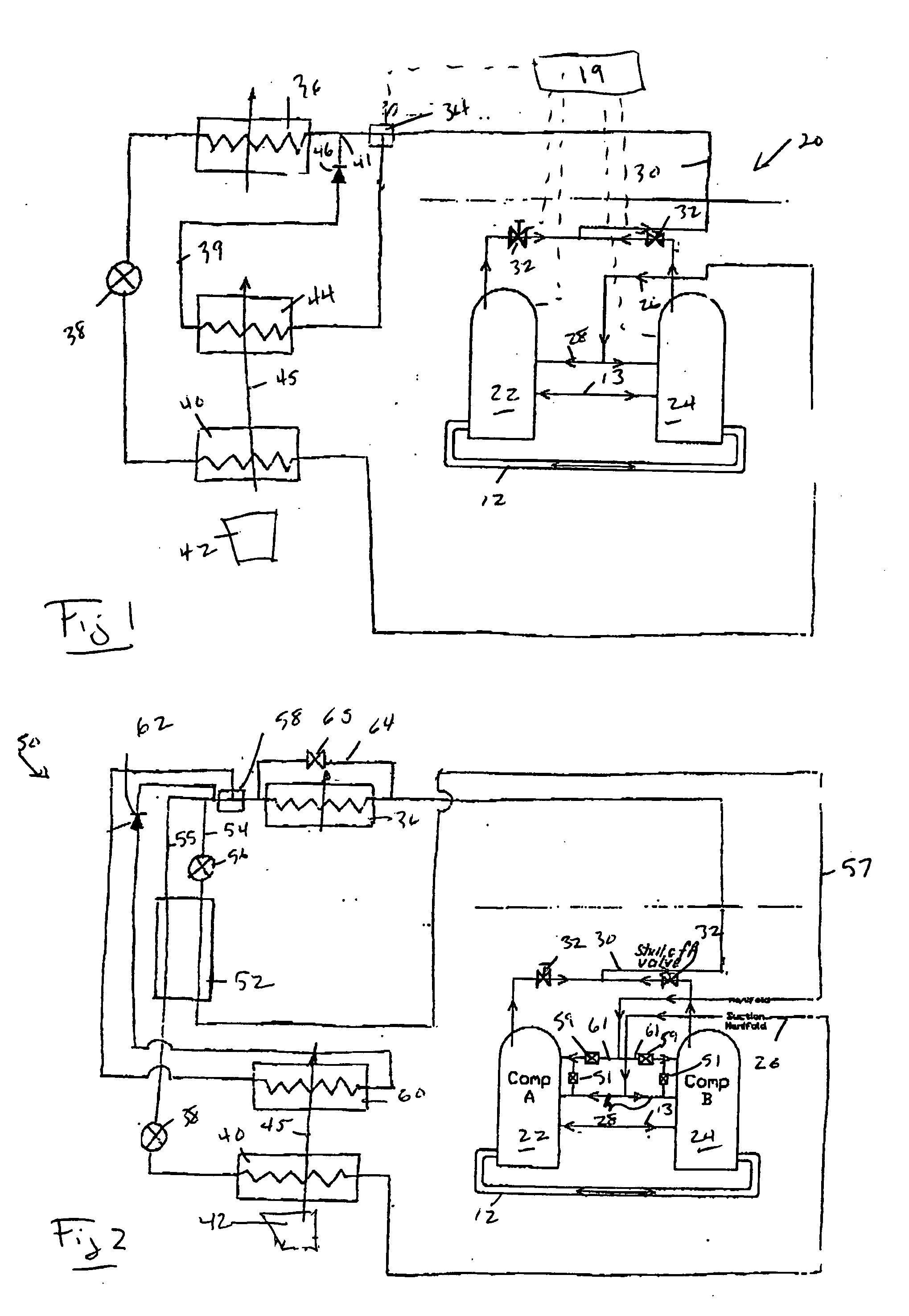

embodiment 50

[0017]FIG. 2 shows another embodiment 50. There are tandem economized compressors 22 and 24 delivering refrigerant to a discharge manifold 30. Downstream of this manifold is a condenser 36, a main expansion device 38, and an evaporator 40. An air moving device 42 blows air over evaporator 40. Refrigerant is returned to a suction manifold 26, and through lines 28 back to the individual suction ports of compressors 22 and 24. Compressors 22 and 24 also have intermediate pressure, or economizer, ports communicating through lines 61 and economizer manifold 57 to the refrigerant system. Economizer lines 61 may incorporate shutoff valves 59 in order to switch between economizer and conventional modes of operation for each individual compressor. Bypass valves 51 allow the compressors to be unloaded, such that either or both of the compressors can be operated at a reduced capacity.

[0018] An economizer loop is incorporated in the refrigerant system 50 downstream of the condenser 36. In the e...

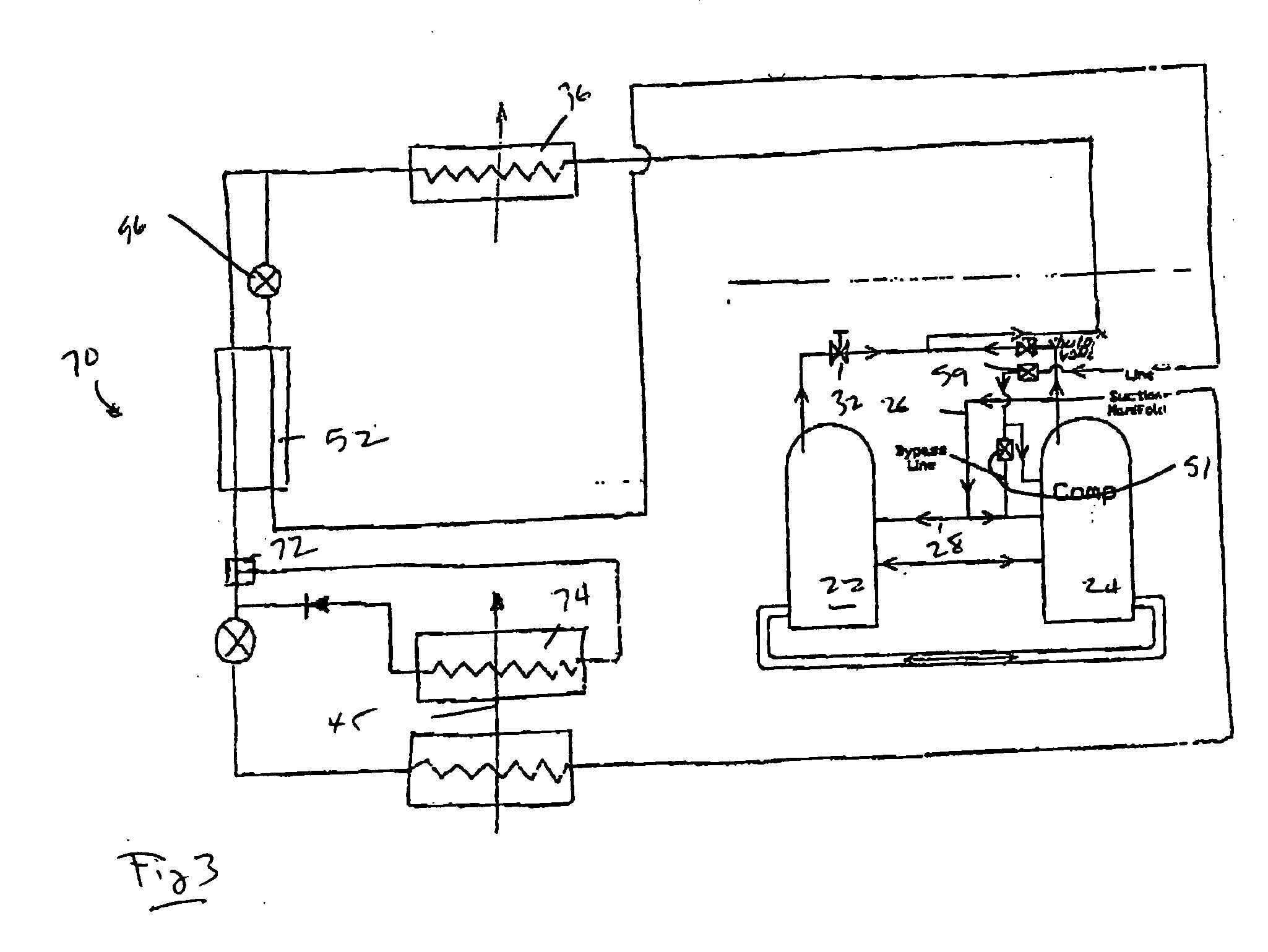

embodiment 70

[0025]FIG. 3 shows yet another embodiment 70. In embodiment 70, the reheat coil 74 communicates with the main cycle refrigerant by means of a three-way valve 72 downstream of the economizer heat exchanger 52. Thus, there would be a warm liquid refrigerant circulated through the reheat coil. Further, the compressors 22 and 24 are provided with a bypass line through valve 51 on only one of the two compressors (here compressor 24). Further, the economizer fluid is returned through line 28 to only one of the two compressors (here compressor 24 as well). While this embodiment does not provide the extreme number of steps of control provided by FIG. 2 embodiment, it does provide additional control when compared to a system that does not have tandem compressors, an economizer cycle or a reheat coil. The two tandem compressors 24 and 22 can still be operated independently, or in combination. The economizer cycle would only be utilized in combination with operation of compressor 24. Any numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com