Watercraft

a technology for watercraft and stern, applied in waterborne vessels, vessel parts, marine propulsion, etc., can solve the problems of large space requirement within the stern region for the raised underwater transmission and propeller, the tilting of the outboard motor, and it is almost impossible for the person steering the watercraft to continuously monitor the water surface and underwater topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

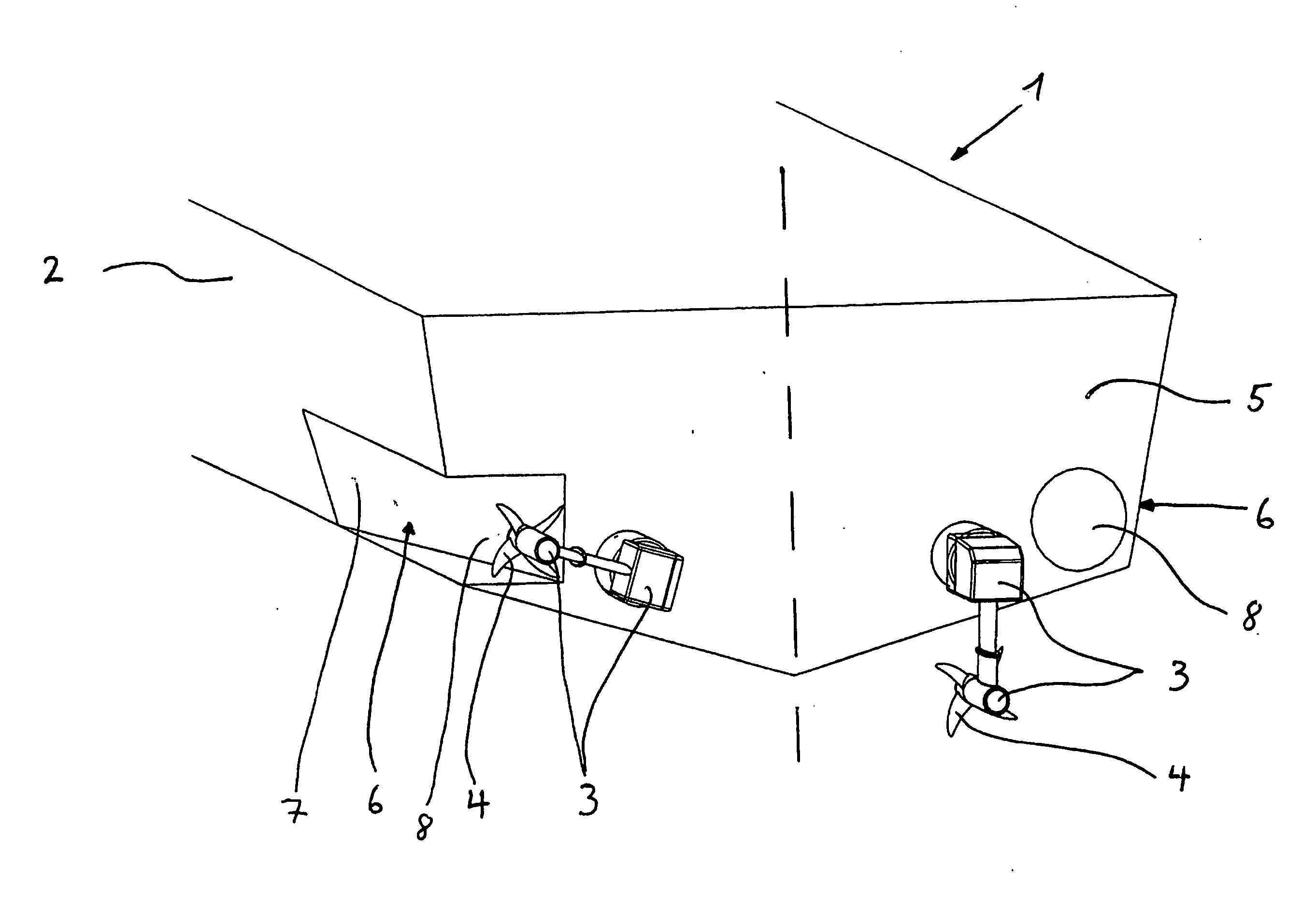

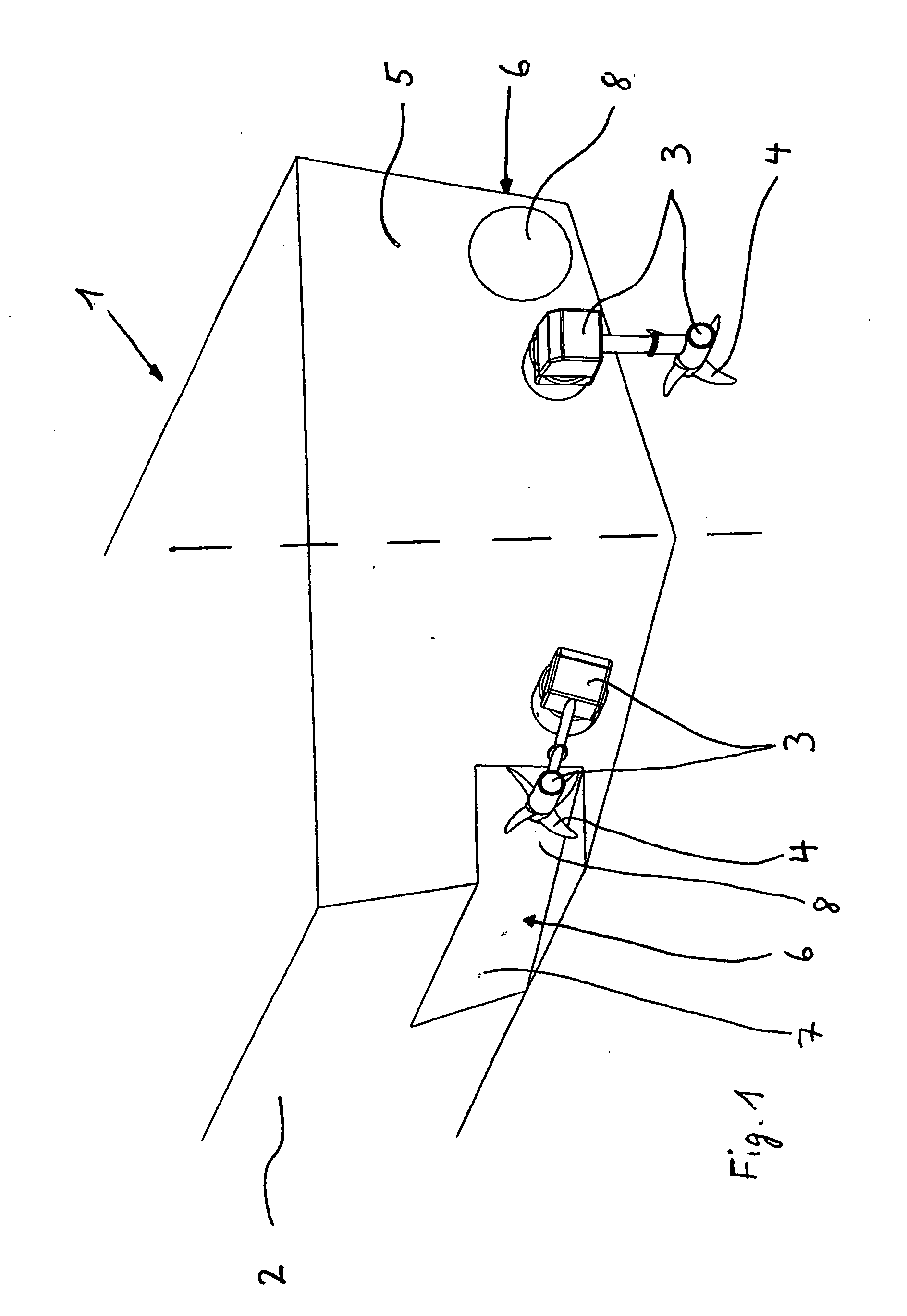

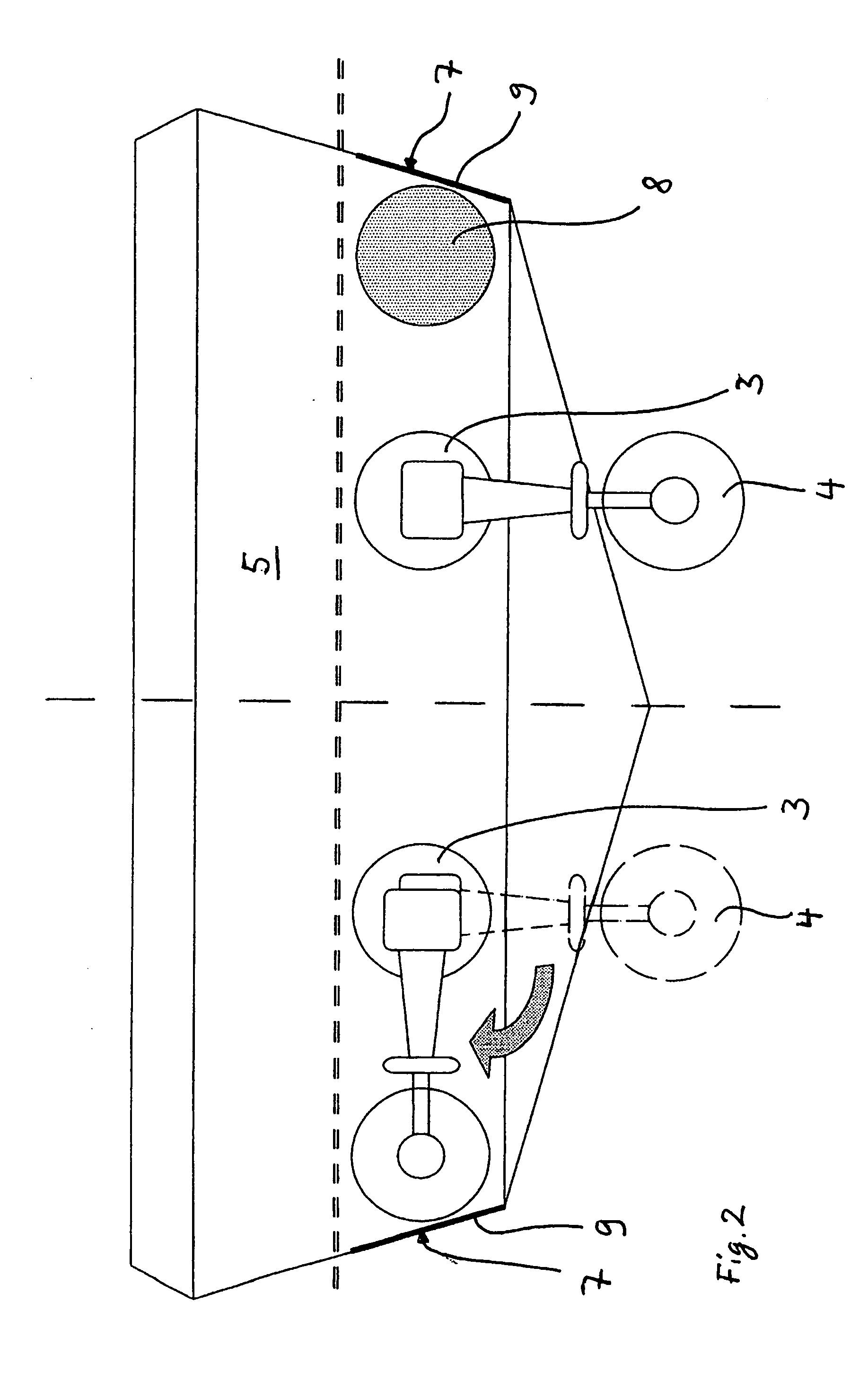

[0006] The goal of the invention is to avoid the above-described disadvantages in a watercraft of prior art, and to provide a system for watercraft which has a small space requirement at the stern of the watercraft, while additionally enabling the watercraft be to utilized in various ways, such as, for example, providing a high startup thrust for water-skiing, little resistance at high speeds, and no projecting drive components in situations of shallow waters.

[0007] According to the invention, the above advantages are achieved by the features of the first claim.

[0008] The core idea of the invention is, in other words, that at least one section of the underwater transmission and the propeller are able to be pivoted by certain means laterally relative to the watercraft.

[0009] The advantages of the invention involve, among other things, the fact that a radially pivotable underwater transmission allows for a space-saving underwater transmission having an unmodified thrust direction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com