Device for checking welded joint of plunger

A technology of inspection device and live column, which is applied in the direction of using liquid/vacuum to measure liquid tightness and applying stable tension/pressure to test the strength of materials, etc. It can solve problems such as bending deformation, coating damage, and finished product damage. Achieve the effect of low cost, controllable quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

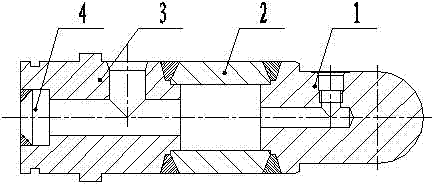

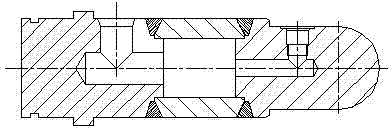

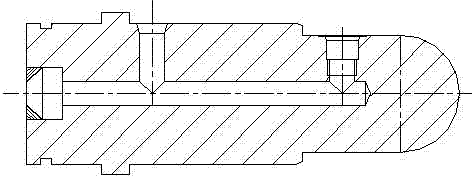

[0014] figure 1 Among them, it is assembled and welded by 4 parts; according to different designs, serial number 3 and serial number 4 can be one part (see figure 2 ), serial number 1, 2, 3 is a part (see image 3 ), or serial number 1 and serial number 2 can be one part (see Figure 4 ). The detection device is sleeved on the outside of the workpiece to be inspected.

[0015] The sealing ring (6) is arranged on the blocking piece (5) in the present invention, and the outside of the blocking piece (5) is positioned by the sleeve (7), and the sleeve is fixed by the screw (8).

[0016] The sleeve 7 of the present invention is provided with three screw holes threadedly connected with the screws 8 . The blocking member 5 is provided with a concave ring-shaped card-loading groove. The rubber ring 6 is an O-shaped rubber ring. After the sealing device is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com