PDMS valve-less micro pump structure and method for producing the same

a valveless, micro-pumping technology, applied in the direction of flexible member pumps, machines/engines, positive displacement liquid engines, etc., can solve the problems of brittle silicon-base materials for producing micro-pumping, inherent fatigue and pitting problems that cannot be neglected, and the manufacturing process of microscopic pumps cannot meet the rapid production requirements. , to achieve the effect of simple structure, low cost and more bio-compatibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

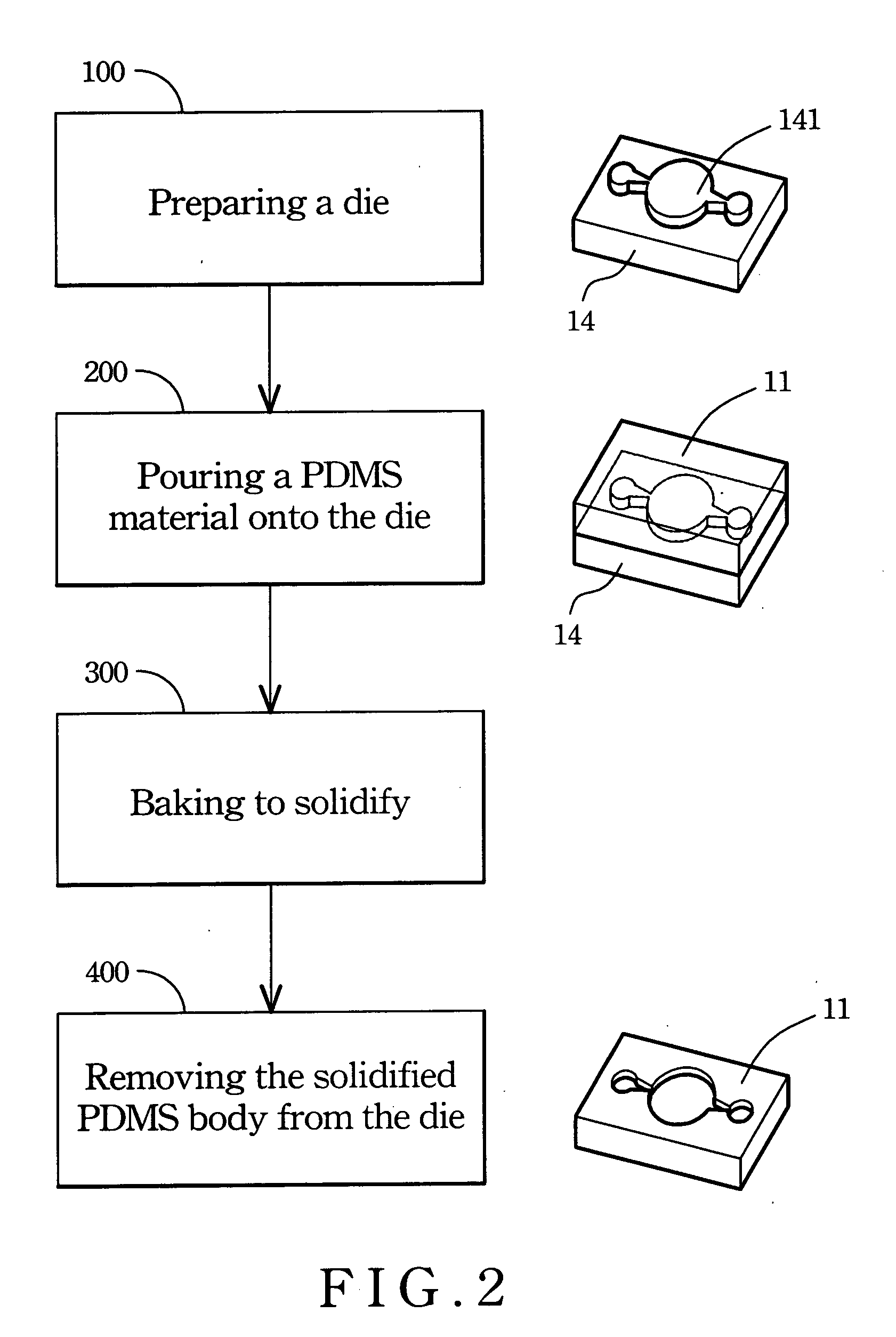

[0047] The invention disclosed herein is directed to a PDMS valve-less micro pump structure and a method for producing the same. In the following description, numerous details are set forth in order to provide a thorough understanding of the present invention. It will be appreciated by one skilled in the art that variations of these specific details are possible while still achieving the results of the present invention. In other instance, well-known components are not described in detail in order not to unnecessarily obscure the present invention.

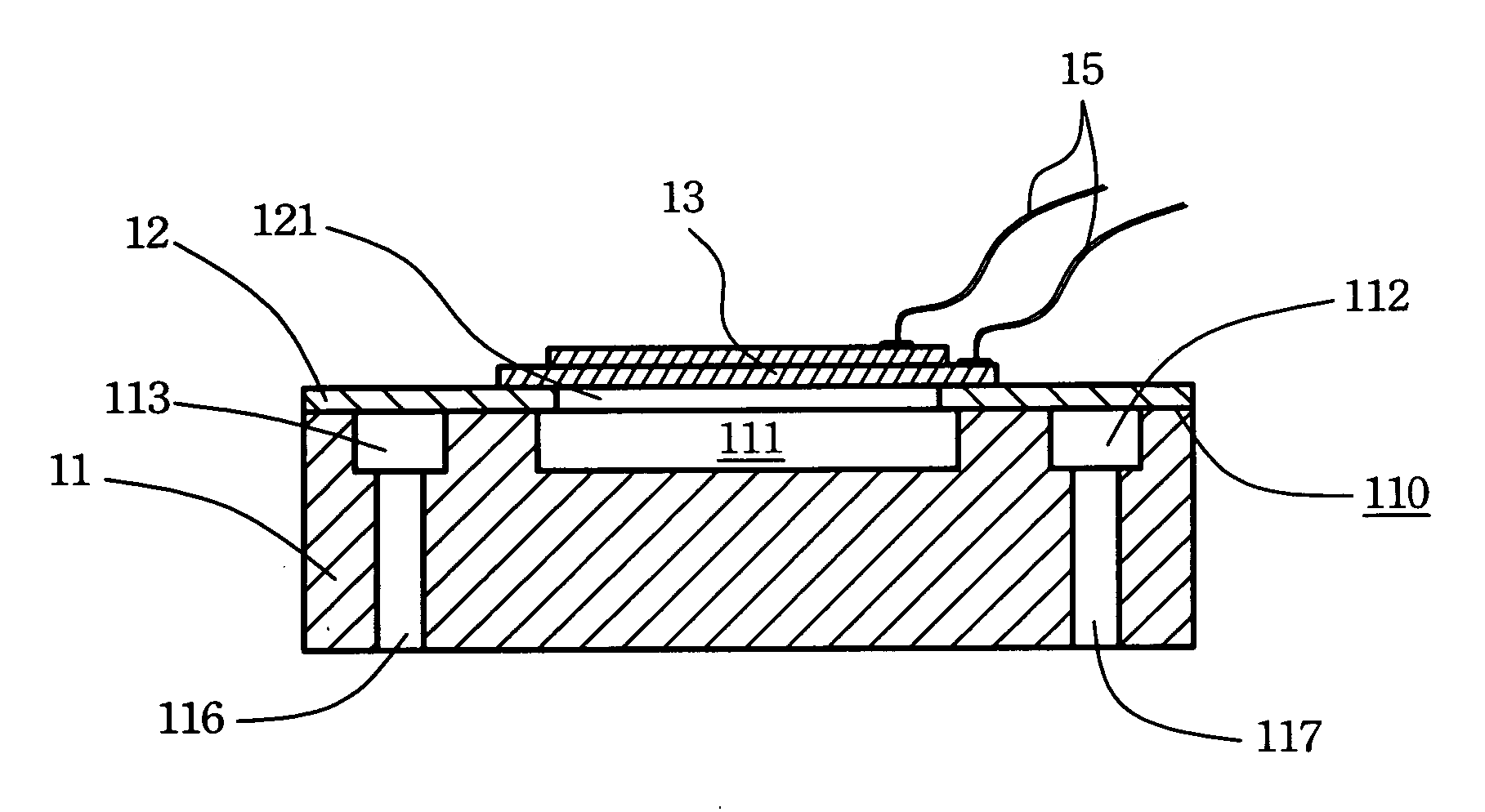

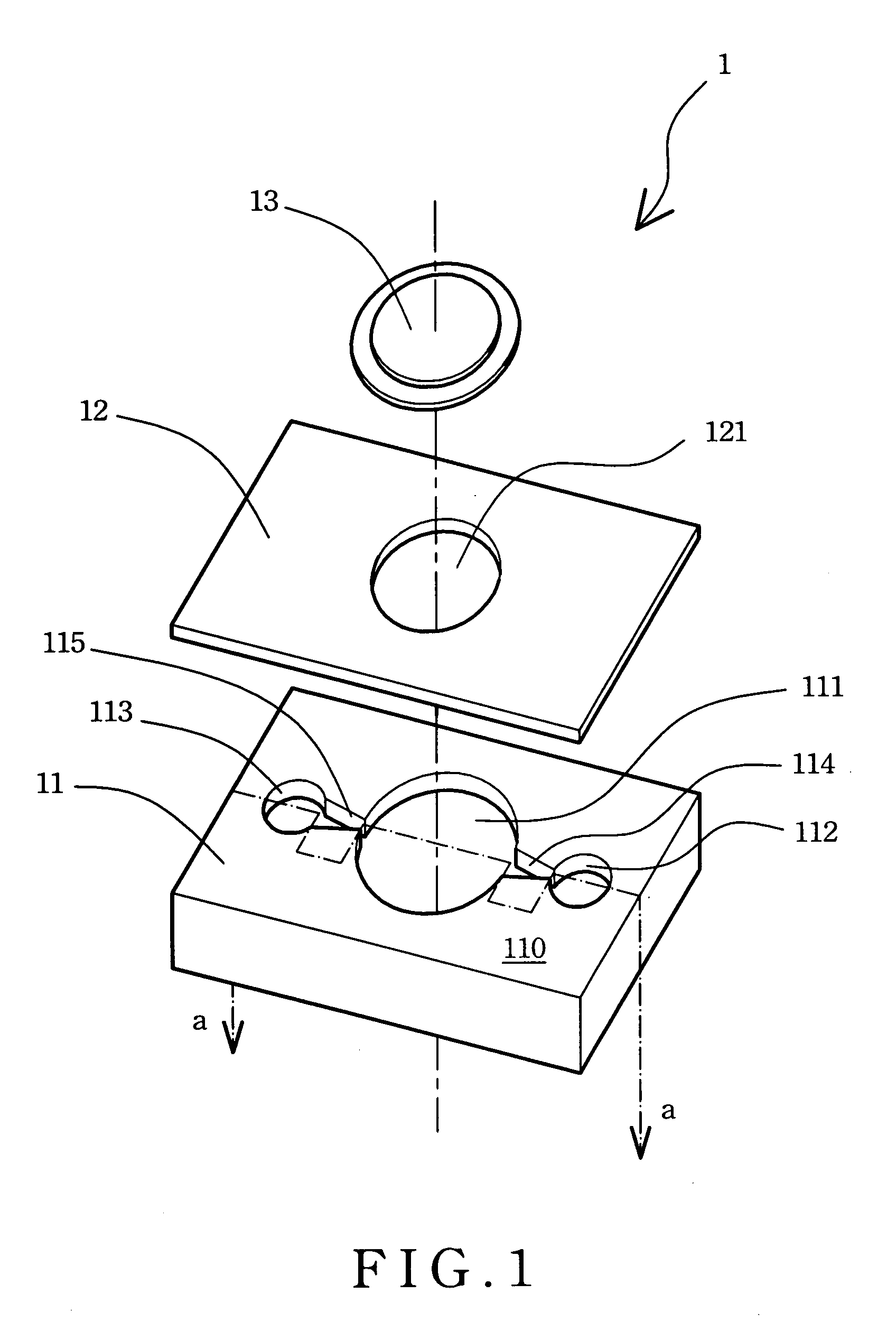

[0048] Referring now to FIG. 1, a perspective exploded view of a preferred PDMS valve-less micro pump in accordance with the present invention is shown to mainly have a PDMS body 11, a membrane 12, and a PZT actuator 13.

[0049] The PDMS body 11 of the present invention is an elastomer that can be made of a PDMS material. The PDMS body 11 has a contour surface 110. As shown, the contour surface 110 is curved to form a main cavity 111, a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com