Multi-level semiconductor module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

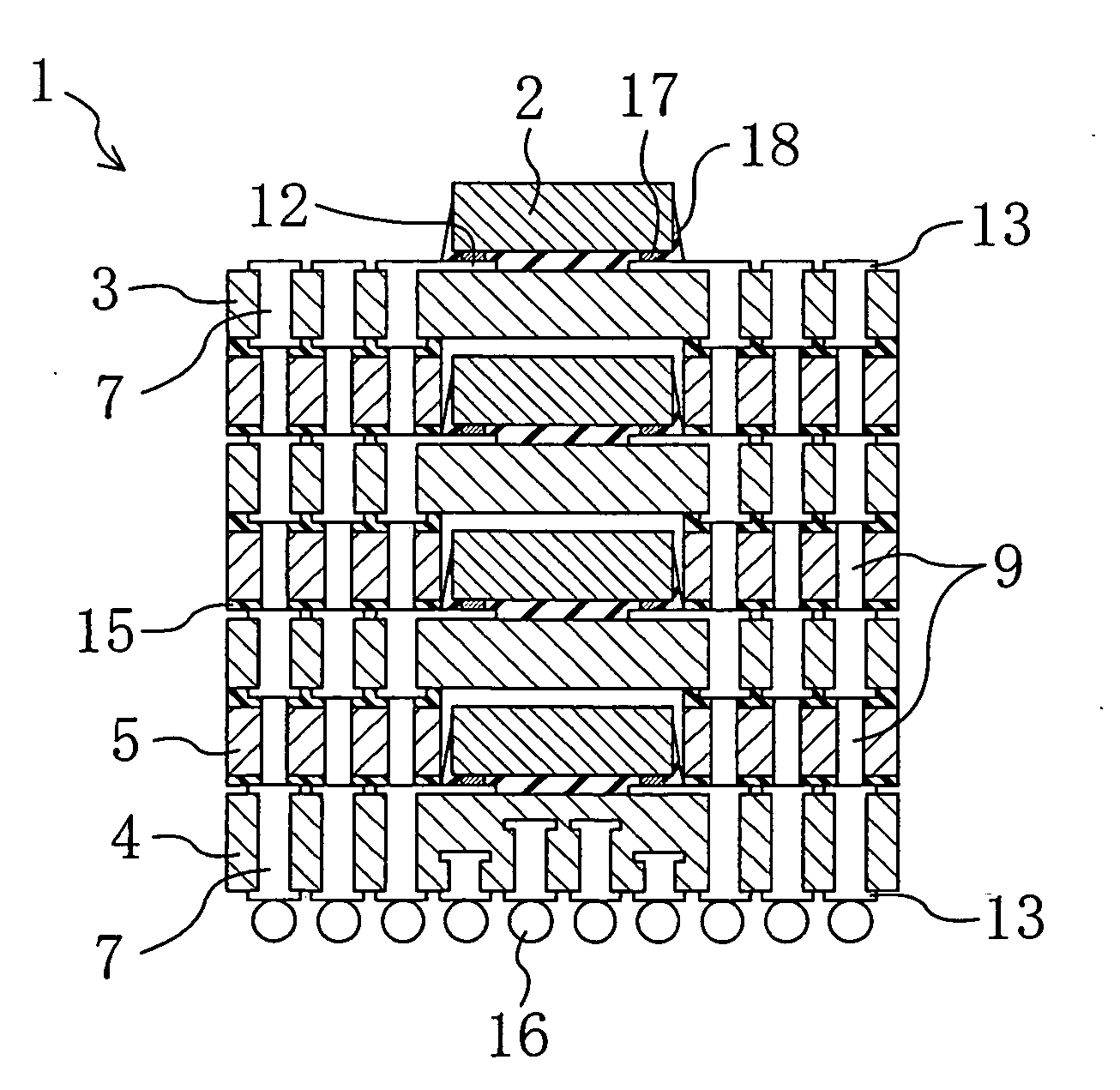

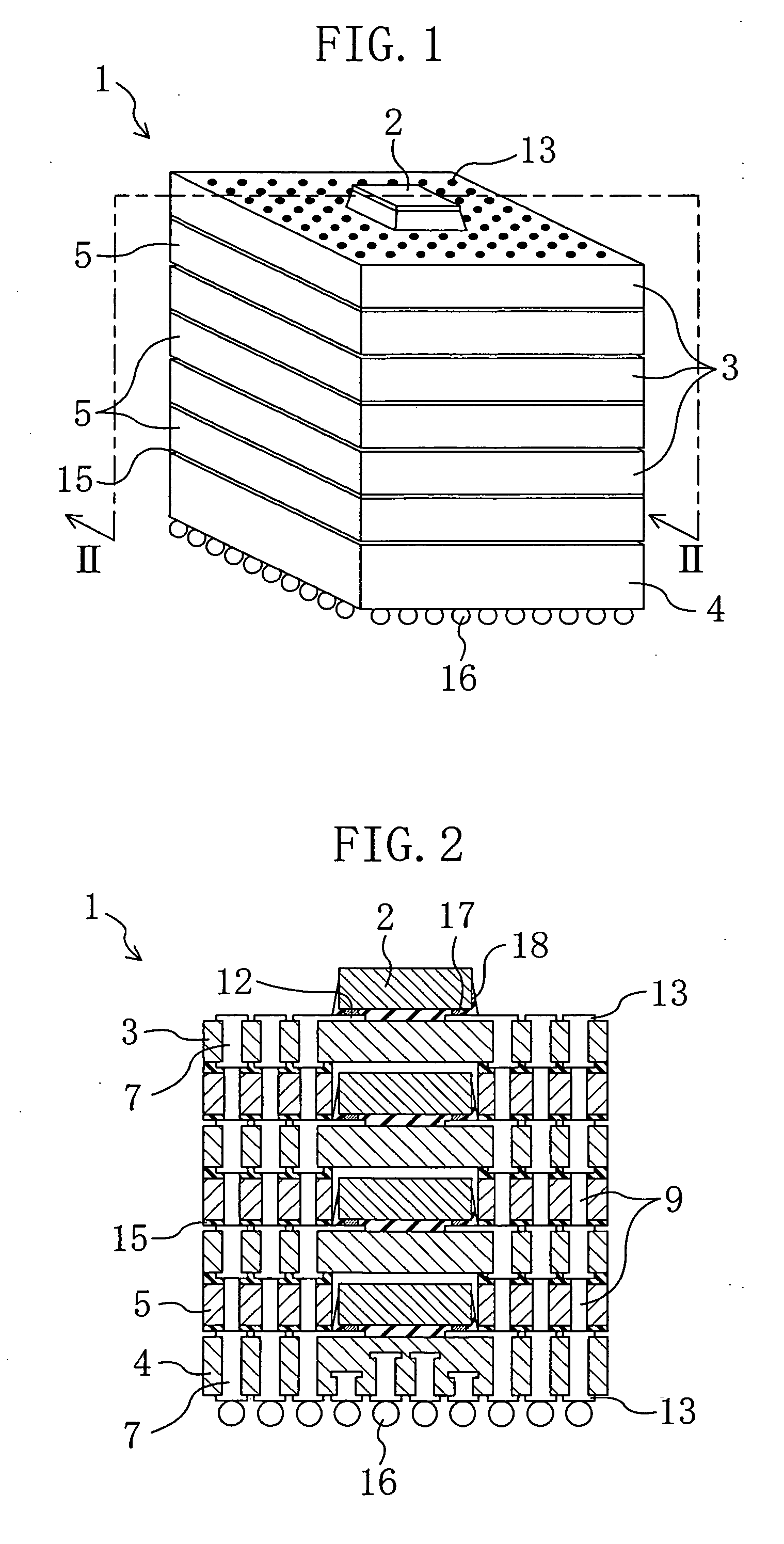

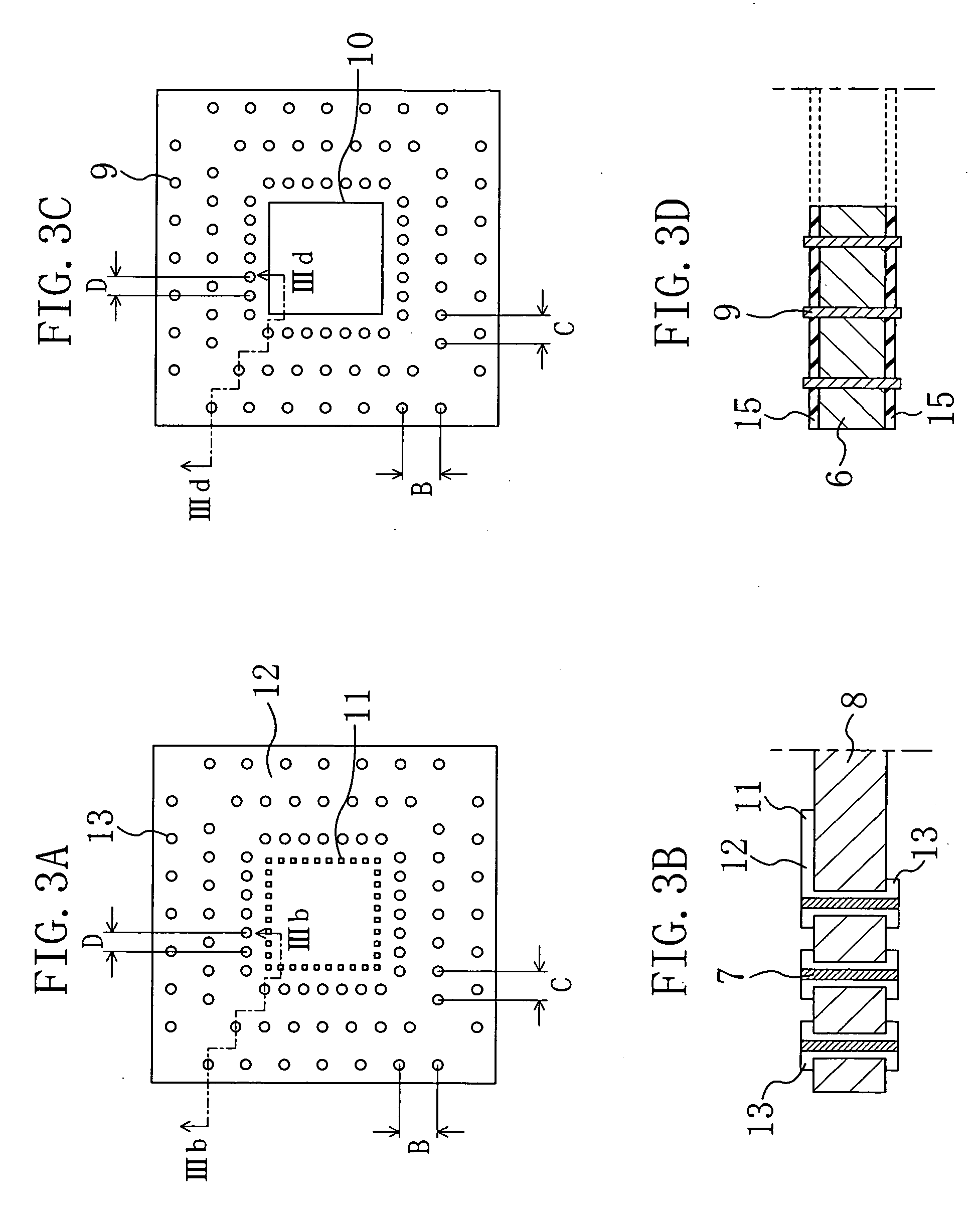

[0039] A multi-level semiconductor module according to a first embodiment of the present invention will be described with reference to FIGS. 1, 2 and 3A through 3D.

[0040]FIG. 1 is a perspective view schematically illustrating an overall structure of a semiconductor module 1 according to each embodiment of the present invention. FIG. 2 is a cross-sectional view of the semiconductor module 1 taken along the line II-II in FIG. 1. FIGS. 3A and 3C are plan views illustrating a first resin board 3 and a sheet member 5, respectively, for use in the semiconductor module 1 of this embodiment. FIG. 3B is a cross-sectional view of the first resin board 3 taken along the line IIIb-IIIb. FIG. 3D is a cross-sectional view of the sheet member 5 taken along the line IIId-IIId. In these drawings, the thicknesses, lengths and shapes of parts of the semiconductor module are selected so as to be easily shown, and therefore are different from those of actual parts. The shapes and numbers of buried cond...

embodiment 2

[0059] A multi-level semiconductor module according to a second embodiment of the present invention will be described with reference to FIGS. 1, 2, and 4A through 4D. FIGS. 4A and 4C are plan views illustrating a first resin board 3 and a sheet member 5, respectively, for use in a semiconductor module 1 according to this embodiment. FIG. 4B is a cross-sectional view of the first resin board 3 taken along the line IVb-IVb. FIG. 4D is a cross-sectional view of the sheet member 5 taken along the line IVd-IVd.

[0060] As illustrated in FIGS. 1 and 2, the semiconductor module of this embodiment is the same as that of the first embodiment except for the arrangement of first buried conductors 7 and second buried conductors 9, and thus description of components already described in the first embodiment will be omitted.

[0061] As illustrated in FIG. 4A, the first buried conductors 7 are basically symmetrical laterally and vertically in plan view in first resin boards 3 and a second resin boar...

embodiment 3

[0065] A multi-level semiconductor module according to a third embodiment of the present invention will be described with reference to FIGS. 1, 2, and 5A through 5D. FIGS. 5A and 5C are plan views illustrating a first resin board 3 and a sheet member 5, respectively, for use in a semiconductor module 1 according to this embodiment. FIG. 5B is a cross-sectional view of the first resin board 3 taken along the line Vb-Vb. FIG. 5D is a cross-sectional view of the sheet member 5 taken along the line Vd-Vd.

[0066] As illustrated in FIGS. 1 and 2, the semiconductor module of this embodiment is the same as that of the first embodiment except for the arrangements and diameters of first buried conductors 7 and second buried conductors 9, and thus description of the same components will be omitted.

[0067] As illustrated in FIG. 5A, the first buried conductors 7 are basically symmetrical laterally and vertically in plan view in first resin boards 3 and a second resin board 4 of this embodiment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com