Method for soil remediation and engineering

a soil remediation and engineering technology, applied in the direction of liquid/fluent solid measurement, fluid pressure measurement, peptide, etc., can solve the problems of contaminated soils and groundwater at industrial, waste disposal and spill sites, serious environmental problems, and migration of colloidal fractions, so as to improve the engineering properties, reduce the energy requirement, and reduce the effect of contaminated soils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0030] Pilot studies have been applied at laboratory scales in 25×2×15 cm and 30×50×40 cm open topped perspex cells (i. e. effectively in two dimensional and three dimensional space). All experiments have been run at <5 volts, using sacrificial cast iron electrodes. Electrodes were fabricated from 25 mm diameter cast iron rods (Grade 250), composition: C 3.48%, Si 2.87%, Mn 0.812%, S 0.099%, P 0.364%, Fe REM. Experiments have been run on a variety of contaminated muds, with groundwater and seawater interstitial pore waters, under unsaturated and saturated conditions. Time scales range from 3 to 400 hours.

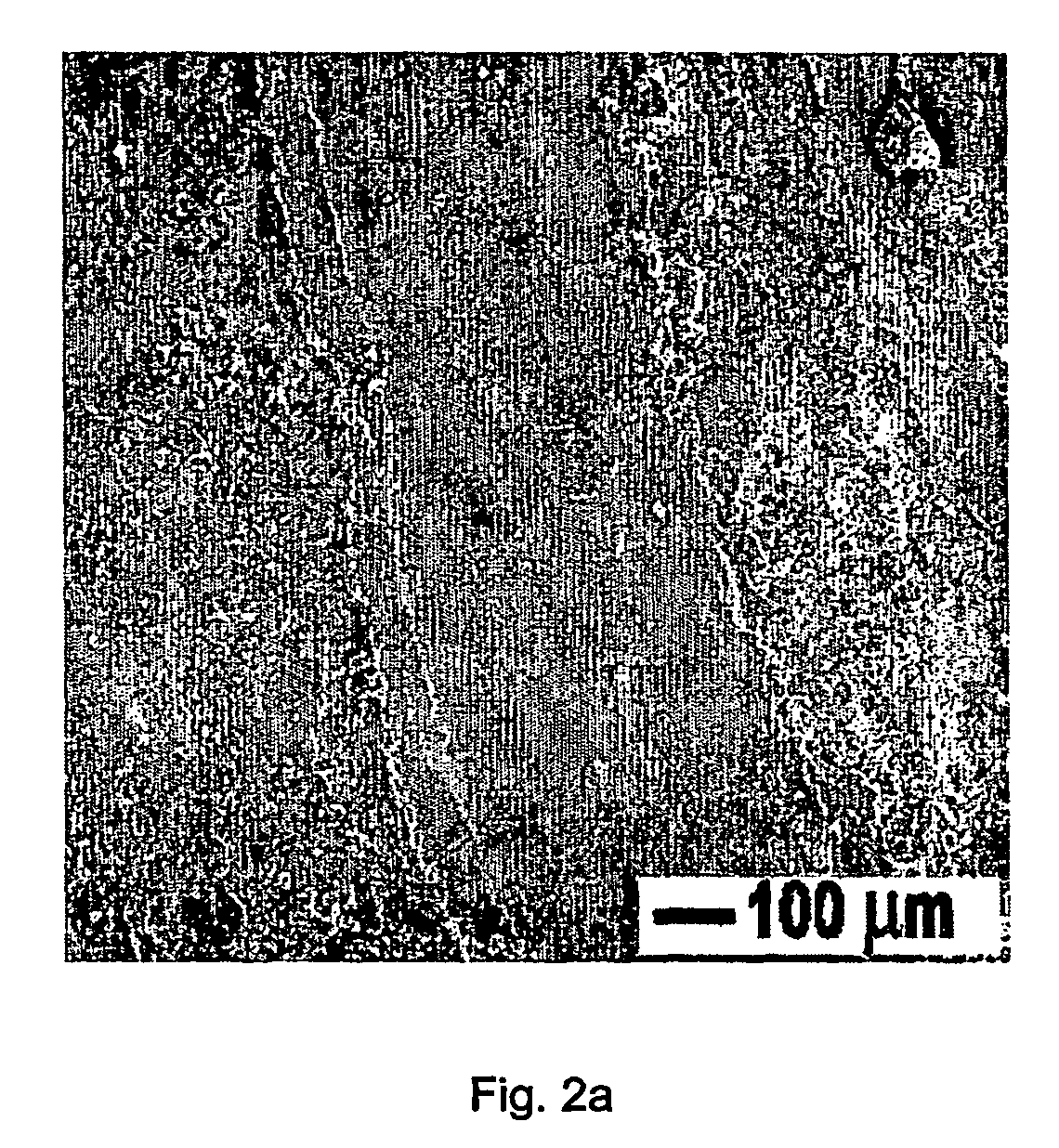

[0031] In experiments using sand, the initial permeability of the sands was 0.48×10−5 m / s, post-treatment permeability (in the iron band) was recorded at 0.19×10−5 m / s. For the mud experiments, initial permeability was typically ˜0.29×10−7, whereas treated material permeability (in the iron band) was recorded at 10−9, or less, i.e. practically impervious. In addition, clear dewater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com