Hydrogen-assisted electrolysis processes

a technology of hydrogen-assisted electrolysis and alkali metal, which is applied in the direction of electrolysis components, instruments, optics, etc., can solve the problems of high market price of sodium, high energy consumption, and dominant cost, and achieves efficient and cost-effective processes, reduce cell potential, and reduce cell potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

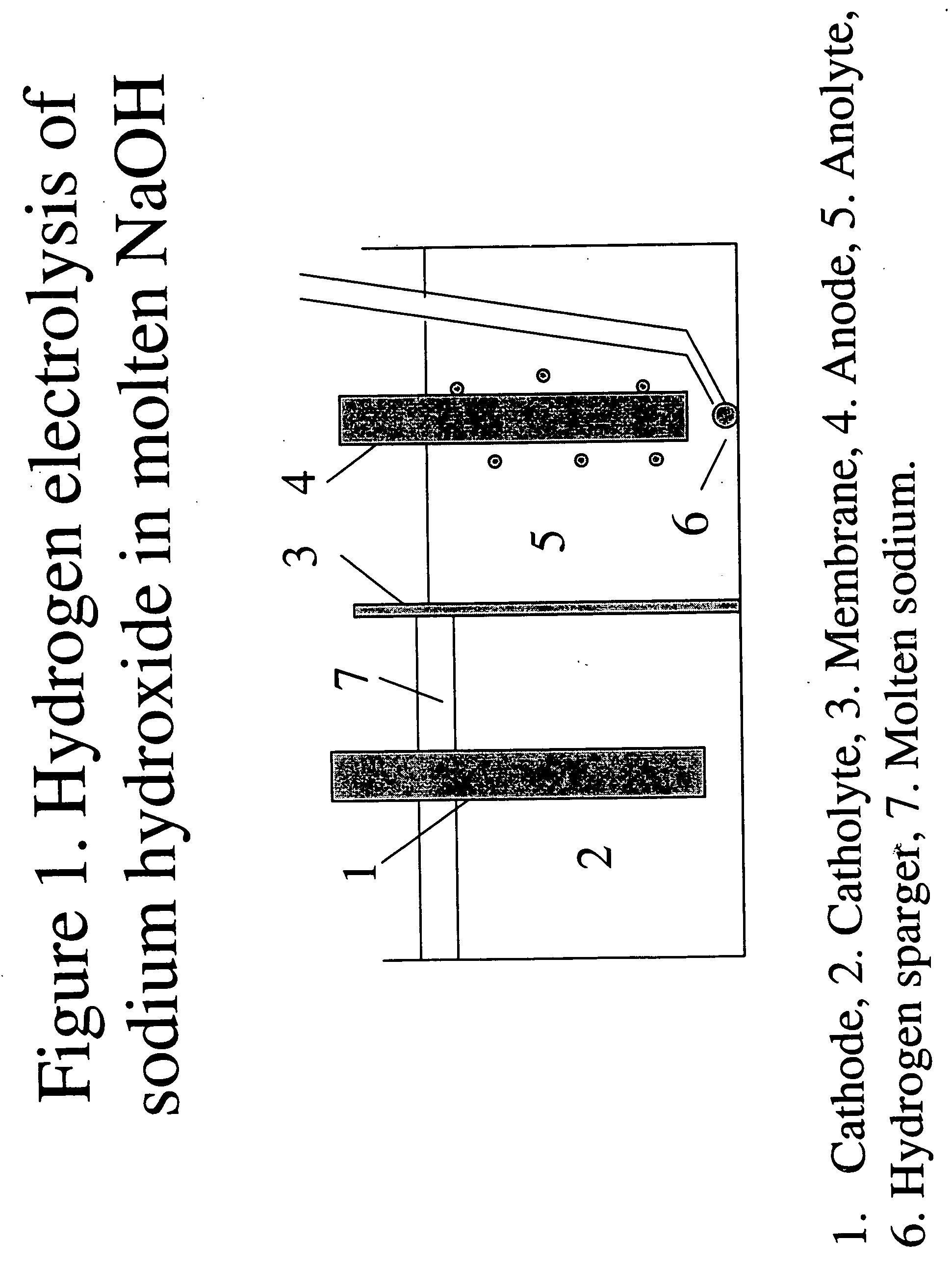

Hydrogen-Assisted Electrolysis Applied to Electrolysis of molten sodium Hydroxide to Make Sodium

[0064] The electrochemical cell was contained in a nickel crucible. The crucible was submerged into sand at the bottom of a glass jar. The glass jar was closed with an airtight seal. The jar was placed in a heating mantle for heating and drying the NaOH, and then to maintain the cell at the desired reaction temperatures. The crucible was loaded with NaOH and dried under flowing N2 gas at 460° C. overnight. A nickel frit electrode was used on the anode side, while a nickel wire electrode was used on the cathode side. Both electrodes have connectors for connecting to the electrical power source. After drying, the crucible and its contents were cooled to 340° C., a temperature at which they were maintained throughout the duration of the synthesis.

[0065] The top of the jar has ports that can be used to introduce electrodes, gas inlets and outlets, and a thermocouple. A reference electrode w...

example 2

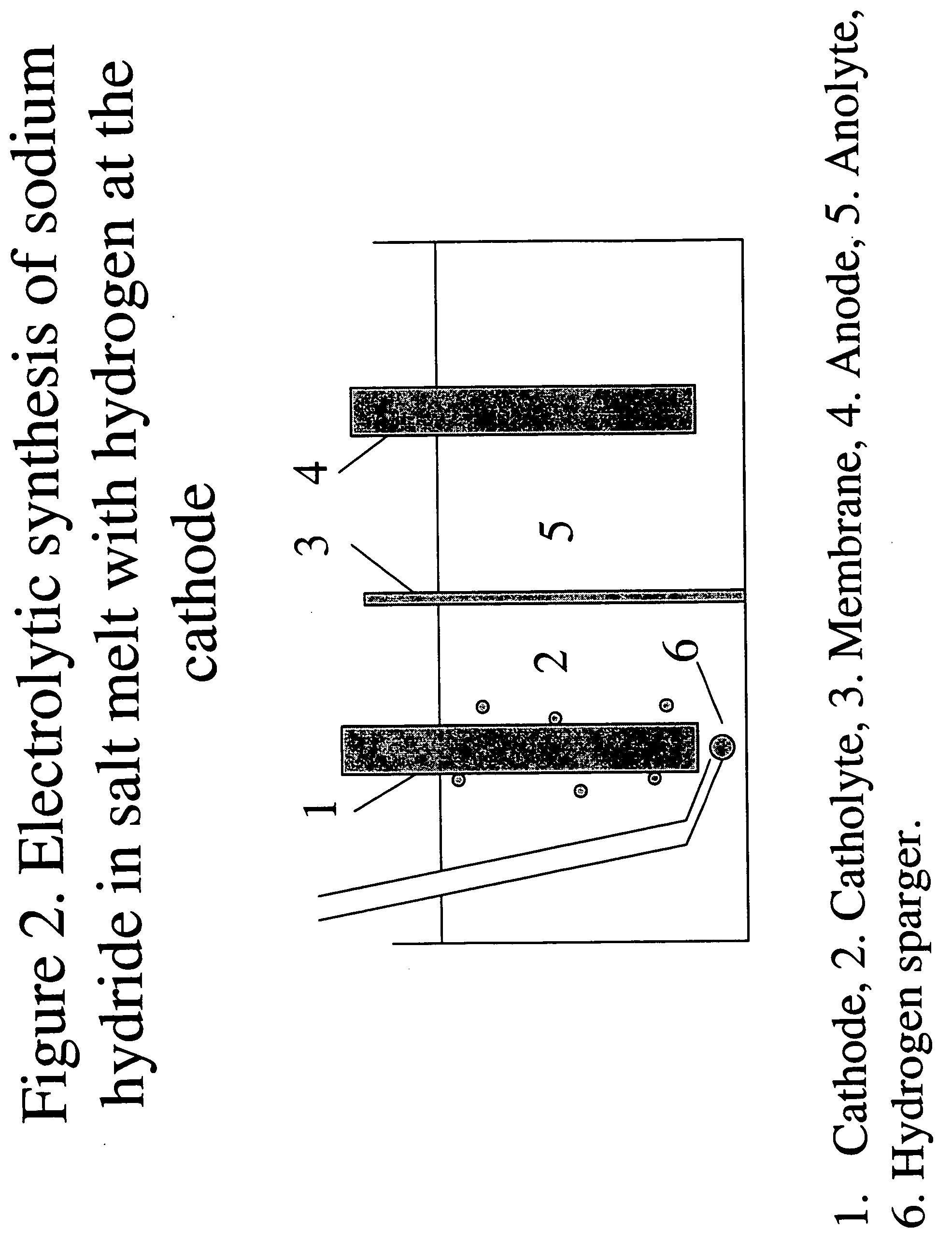

Hydrogen-Assisted Electrolysis Applied to Sodium Metaborate Dissolved in Molten Sodium Hydroxide to Make Sodium Borohydride

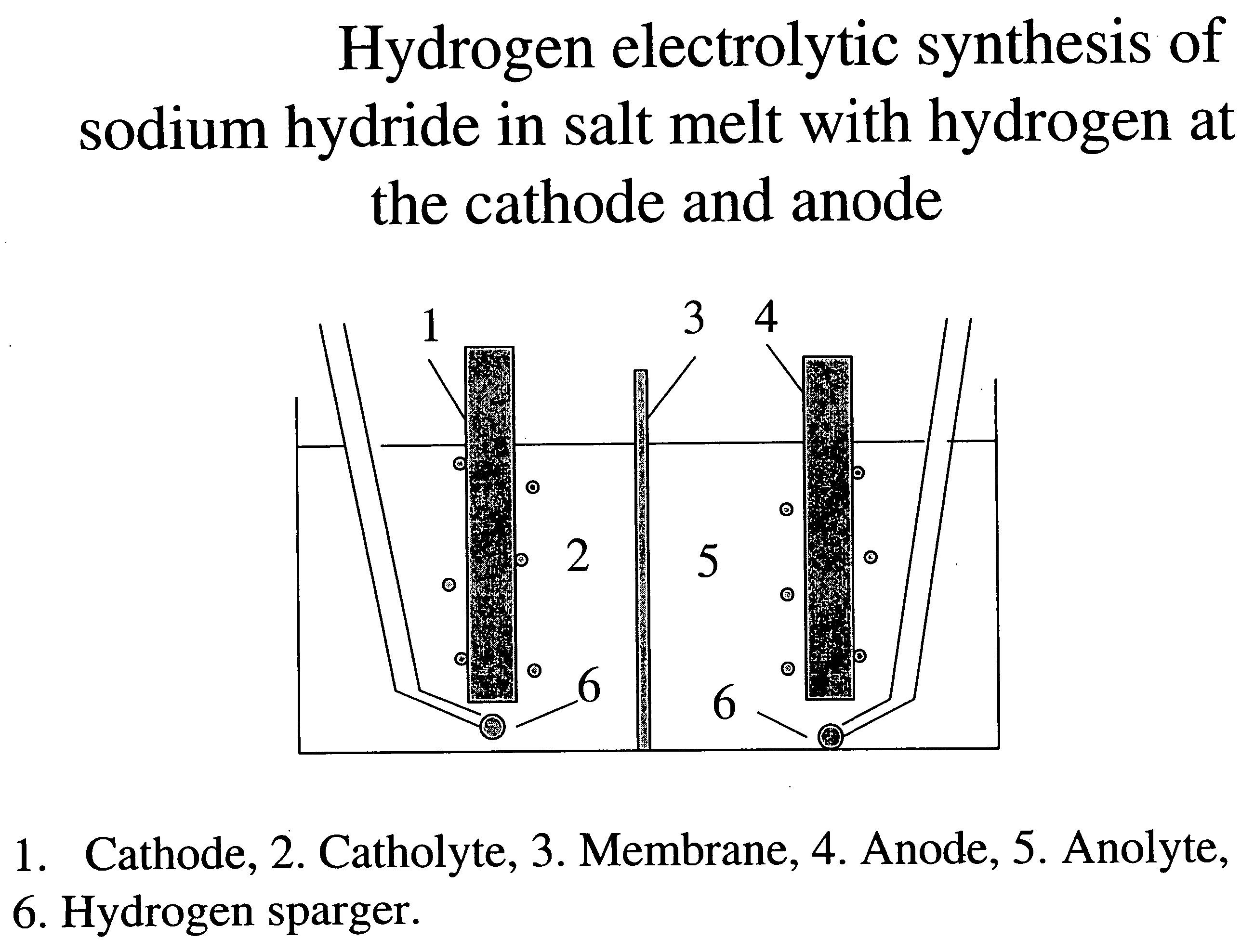

[0068] The electrochemical cell will be contained in a nickel crucible. The crucible will be submerged into sand at the bottom of a glass jar. The glass jar will be closed with an airtight seal. The jar is to be placed in a heating mantle for heating and drying the NaOH and NaOH / NaBO2 mixtures, and then to maintain the cell at the desired reaction temperatures. The crucible will be loaded with NaOH and dried under flowing N2 gas at 460° C. overnight. A nickel frit electrode will be used on both the anode and cathode side. Both electrodes have connectors for connecting to the electrical power source. After drying, the crucible and its contents were cooled to 340° C., a temperature at which they were maintained throughout the duration of the synthesis.

[0069] The top of the jar has ports that can be used to introduce electrodes, gas inlets and outlets, and a ther...

example 3

Hydrogen-Assisted Electrolysis Applied to Sodium Hydroxide Electrolysis in Aqueous Solution to Form Sodium Amalgam

[0073] The electrolytic cell is contained in a crucible which is placed in a glass jar that can be closed with an airtight seal. The crucible will be loaded with an aqueous solution of NaOH. A platinum electrode will be used as the anode. A 2:1:1 mixture of Bi / Pb / Sn mixture (Rose's metal) will be added to the cell to act as the cathode and the alloying material. The platinum electrode should not be in contact with the alloy or the cell body. Both electrodes have connectors for connecting to the electrical power source. The top of the jar has sealable ports that can be used to introduce electrodes, gas inlets and outlets, and a thermocouple. The crucible will be used as a pseudo reference electrode.

[0074] The temperature of the cell will be raised gradually by the heating mantle, until the Rose's metal is melted. The output of the heating mantle will be controlled by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com