Methods and systems for electroplating wafers

a technology of electroplating wafers and substrates, applied in the field of electroplating substrate methods and systems, can solve the problems of large amount of time and labor for plating solution analysis and control, severe penalization of the overall performance of the structure, etc., and achieve the effects of reducing the production rate of breakdown products produced during electroplating, reducing the useable life of plating solution, and reducing the consumption rate of additives enhancing electroplating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

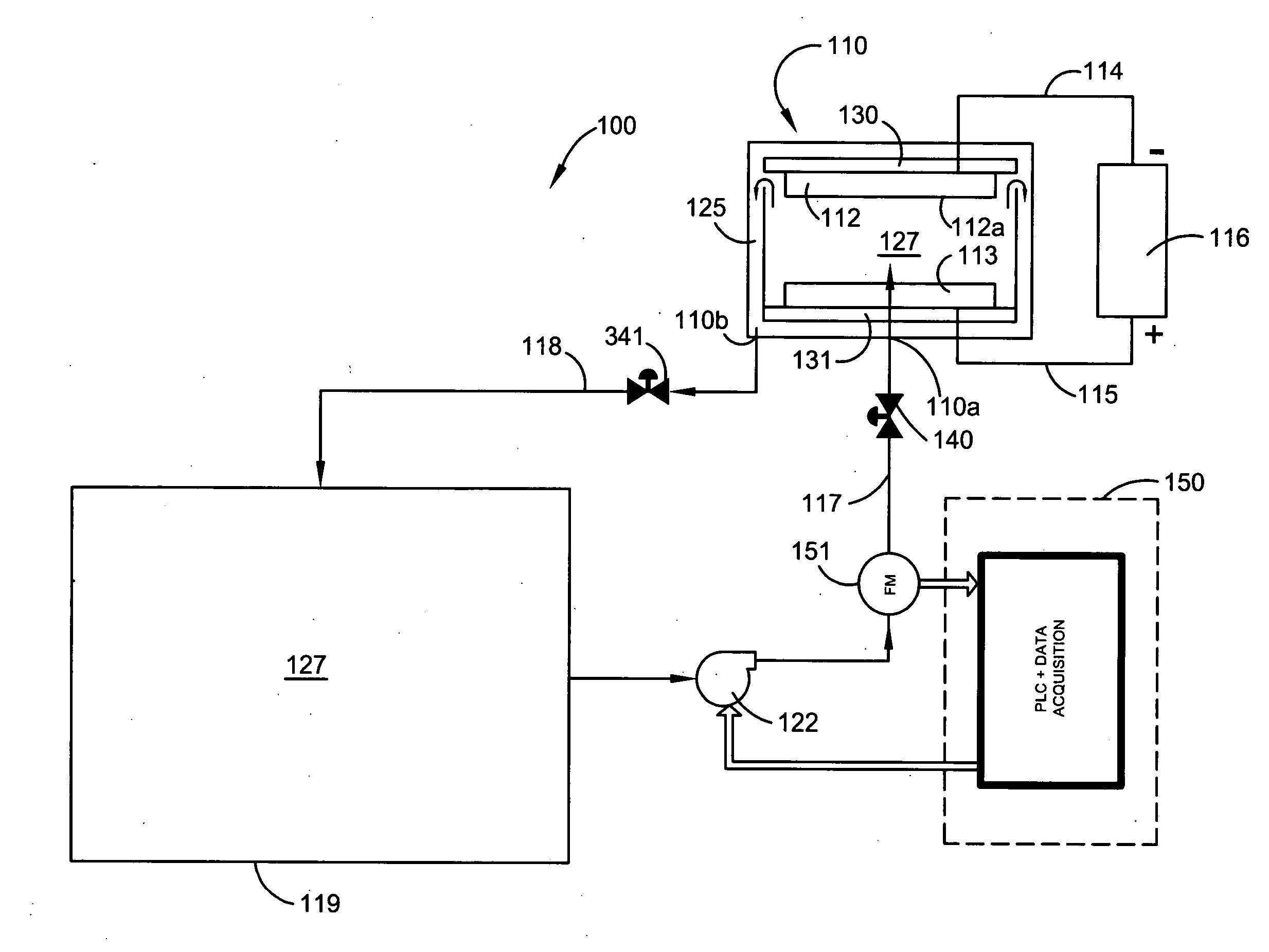

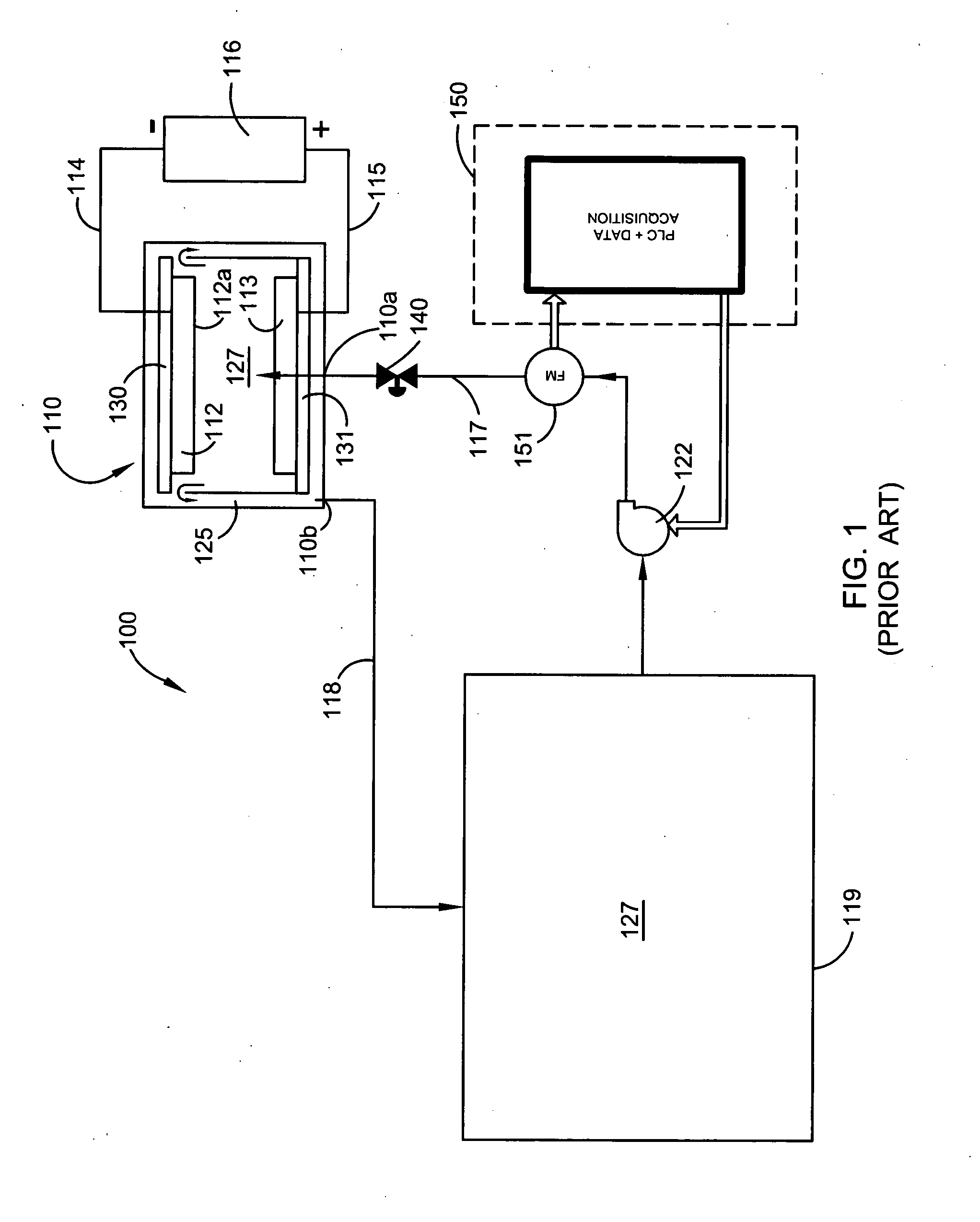

[0020] In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-4 of the drawings in which like numerals refer to like features of the invention. Features of the invention are not necessarily shown to scale in the drawings.

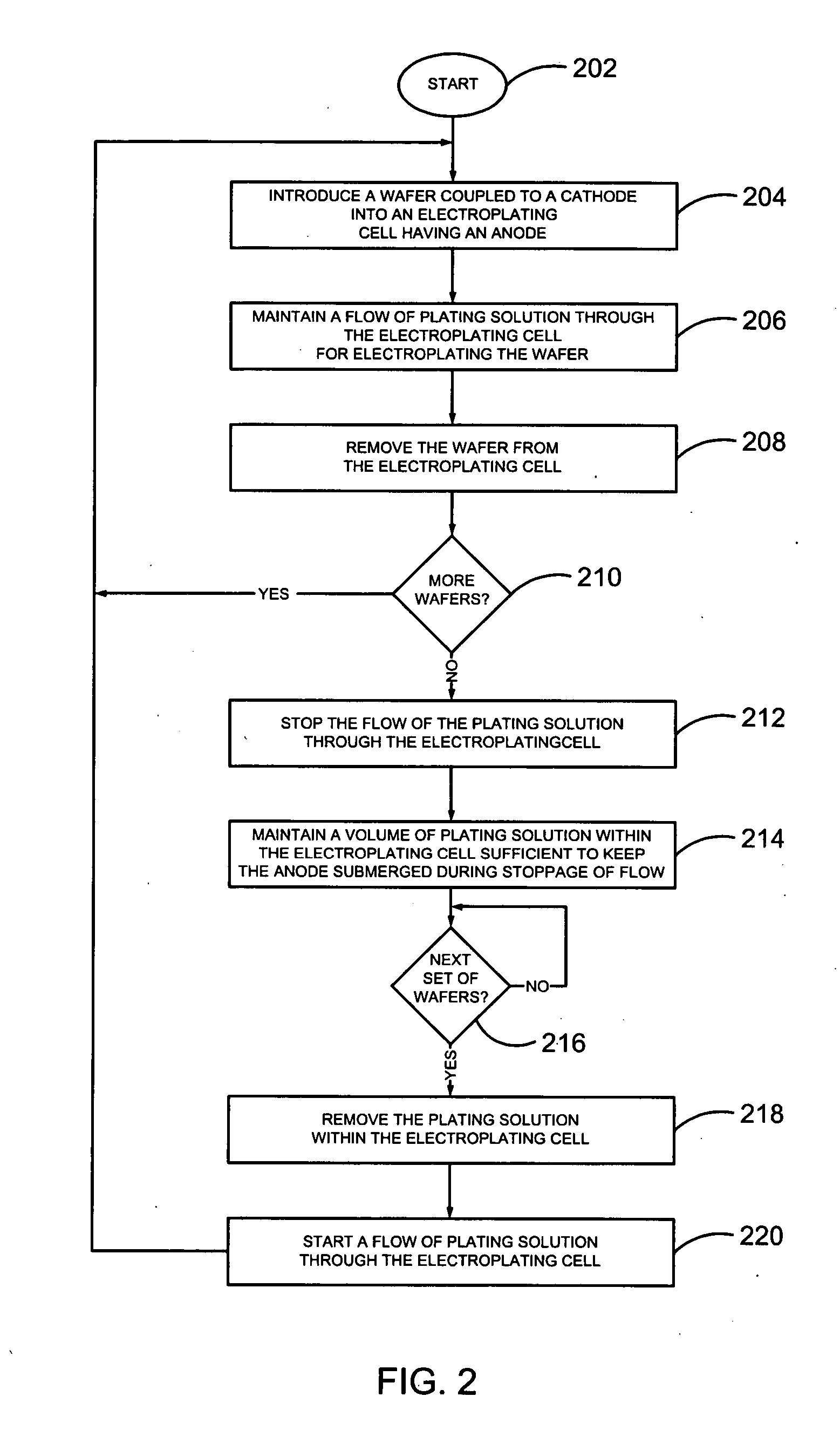

[0021]FIG. 2 is a flowchart which describes an improved method for electroplating wafers in accordance with the present invention. FIGS. 3-4 are process flow diagrams of plating systems 300 and 400 of the present invention within which the steps in the flowchart of FIG. 2 may be employed. While the systems and methods are described primarily with reference to plating a silicon wafer, it will be appreciated by those skilled in the art that other substrates may be plated. Although any suitable system platform may be utilized, the plating system may be based on the type provided by Semitool, Inc. of Kalispell, Mont., U.S.A., for example, the EQUINOX® system platform (EQUINOX is a registered trademark of Semitool, Inc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| time period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com