Aqueous pigmented coating formulation providing for improved opacity

a technology of pigmented coating and opacity, which is applied in the field of aqueous pigmented coating formulations, can solve the problems of affecting other properties, color and shade, and not being desirable for some paper grades, and achieves the effect of improving and increasing the opacity of paper and/or paperboard coated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] In this Example, two aqueous pigmented coating formulations are produced and subsequently applied to paper. The first aqueous pigmented coating formulation is free of an acylated lecithin. The second aqueous pigmented coating formulation comprises an acylated lecithin. The opacity of paper coated with the aqueous pigmented coating formulation comprising an acylated lecithin is then compared to a control basestock that has not been coated with an aqueous pigmented coating formulation (Control 1) and to a paper coated with an aqueous pigmented coating formulation free of an acylated lecithin (Control 2).

[0056] Control 1 and the two aqueous pigmented coating formulations for evaluation are set forth in Table 1:

TABLE 1Amounts of Ingredients expressed as parts per hundredparts pigmentPigment 80:20BinderCalcium(Styrene-carbonate:butadienePro-CoteSamplekaolin clayrubber)4200LecithinOBAControl 1N / AN / AN / AN / AN / AControl 21009.52.0N / A1.0Sample1009.52.00.751.0comprisingacylatedlecithin...

example 2

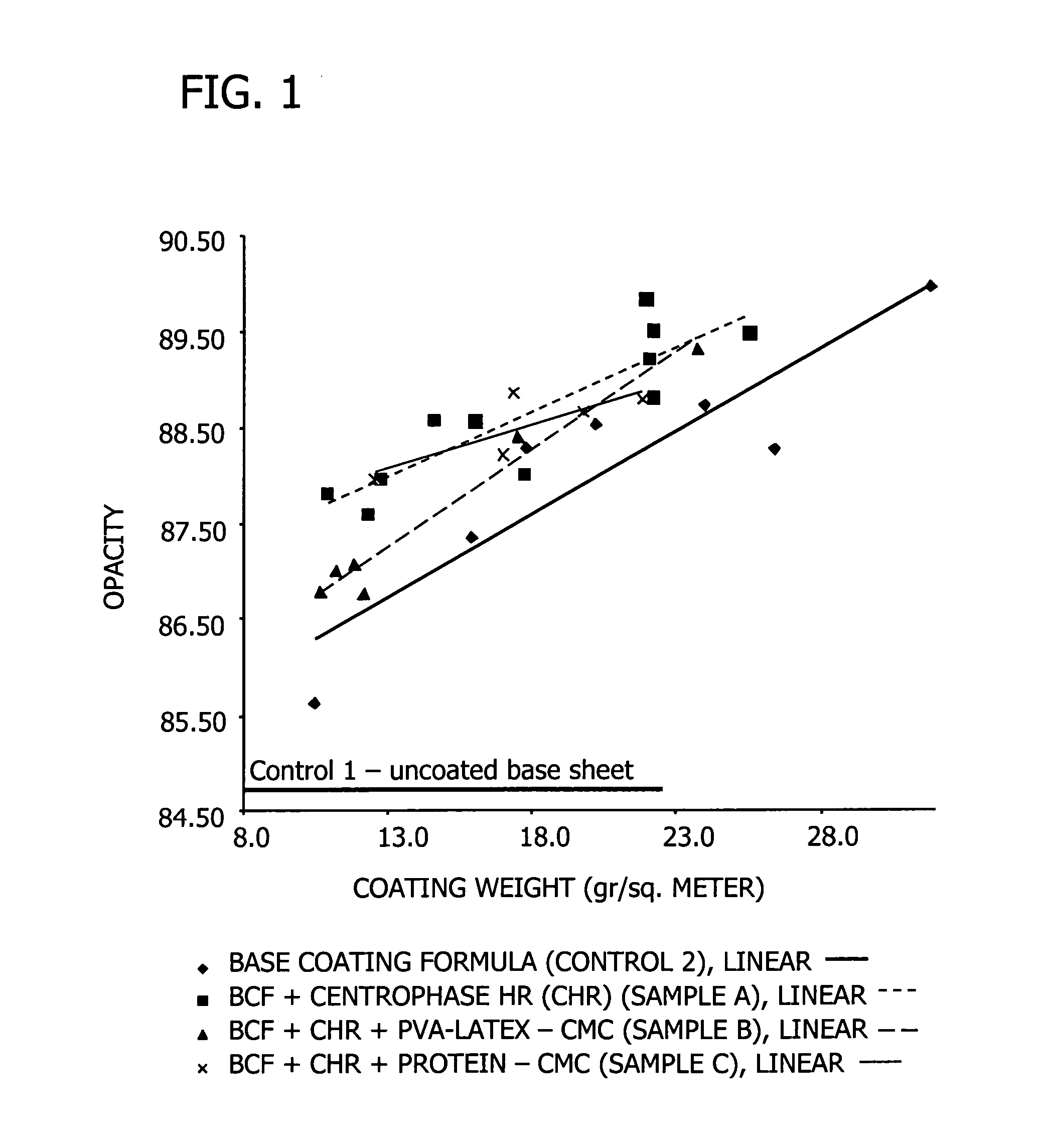

[0065] In this Example, aqueous pigmented coating formulations comprising acetylated lecithin are produced and subsequently applied to paper in various coating weights. The opacities of the paper samples coated with the aqueous pigmented coating formulations are then compared to basestock that has not been coated with an aqueous pigmented coating formulation (Control 1) and to a paper sample coated with an aqueous pigmented coating formulation free of acetylated lecithin (Control 2).

[0066] The aqueous pigmented coating formulations are made using the method of Example 1 with the exception of additionally using polyvinyl alcohol, commercially available in an aqueous solution as Celvol 203S (Celanese Noviant, The Netherlands) as a co-binder. Specifically, when polyvinyl alcohol is included in the aqueous pigmented coating formulation, the polyvinyl alcohol is mixed into the aqueous pigmented solution using constant agitation with a metal four-bladed impeller mixer at a speed of 1500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com