Automated microtome blade changer

a technology of automatic change and microtome, which is applied in the direction of metal sawing devices, metal sawing apparatus, manufacturing tools, etc., can solve the problems of not providing safety features, not revealing a method or apparatus for the change of individual blades, and reducing the chance of being cut accidentally. , the effect of reducing the chance of being cu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

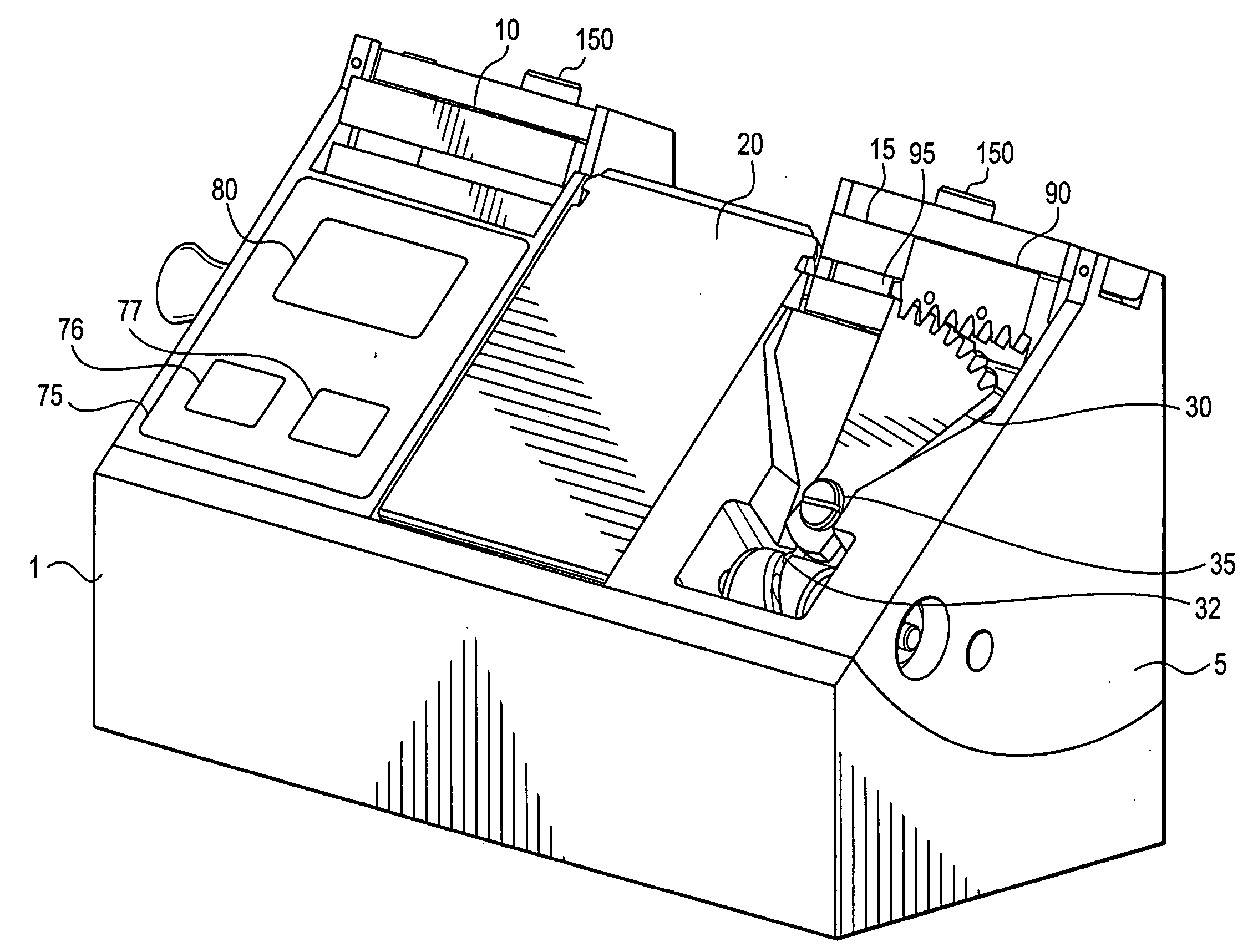

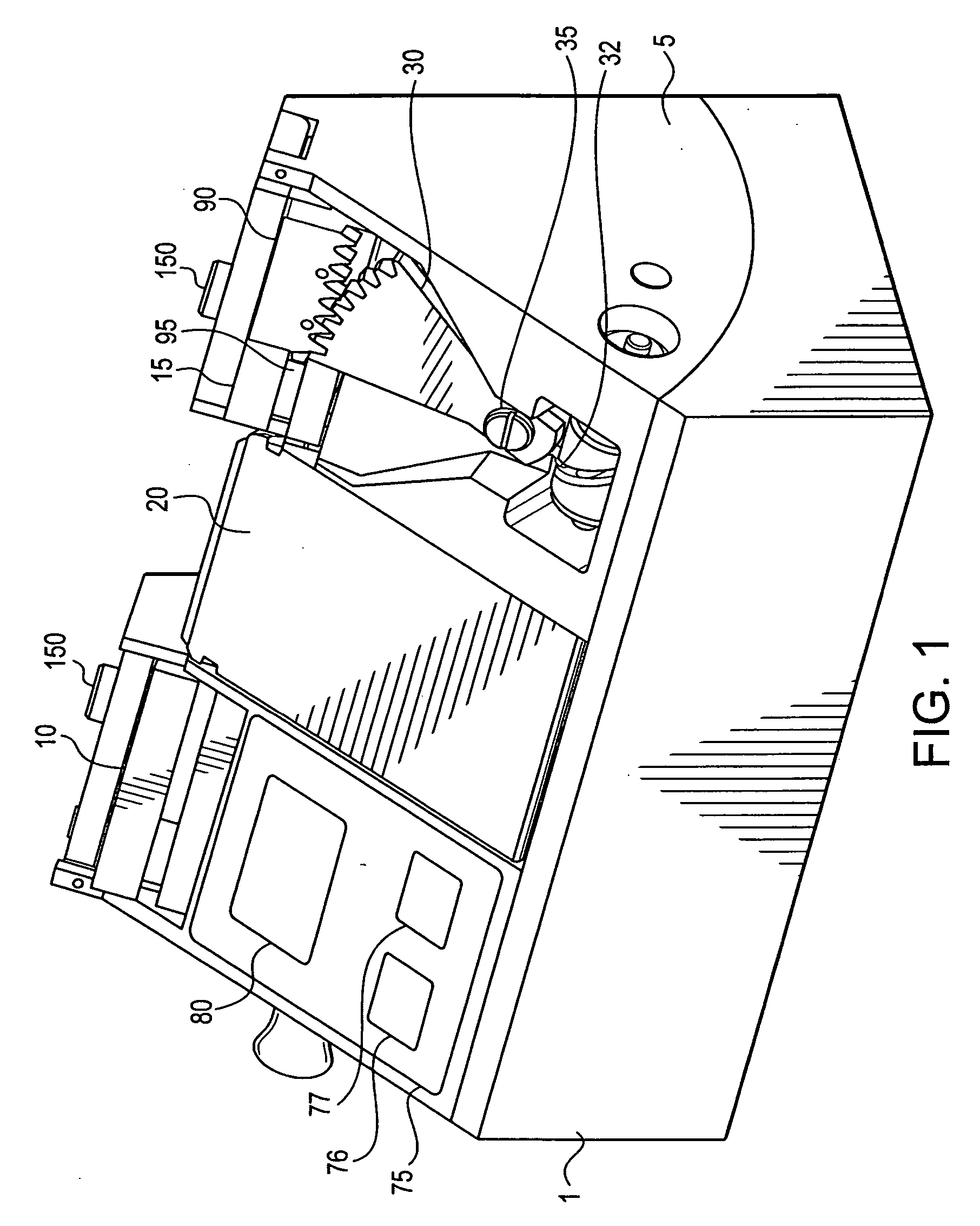

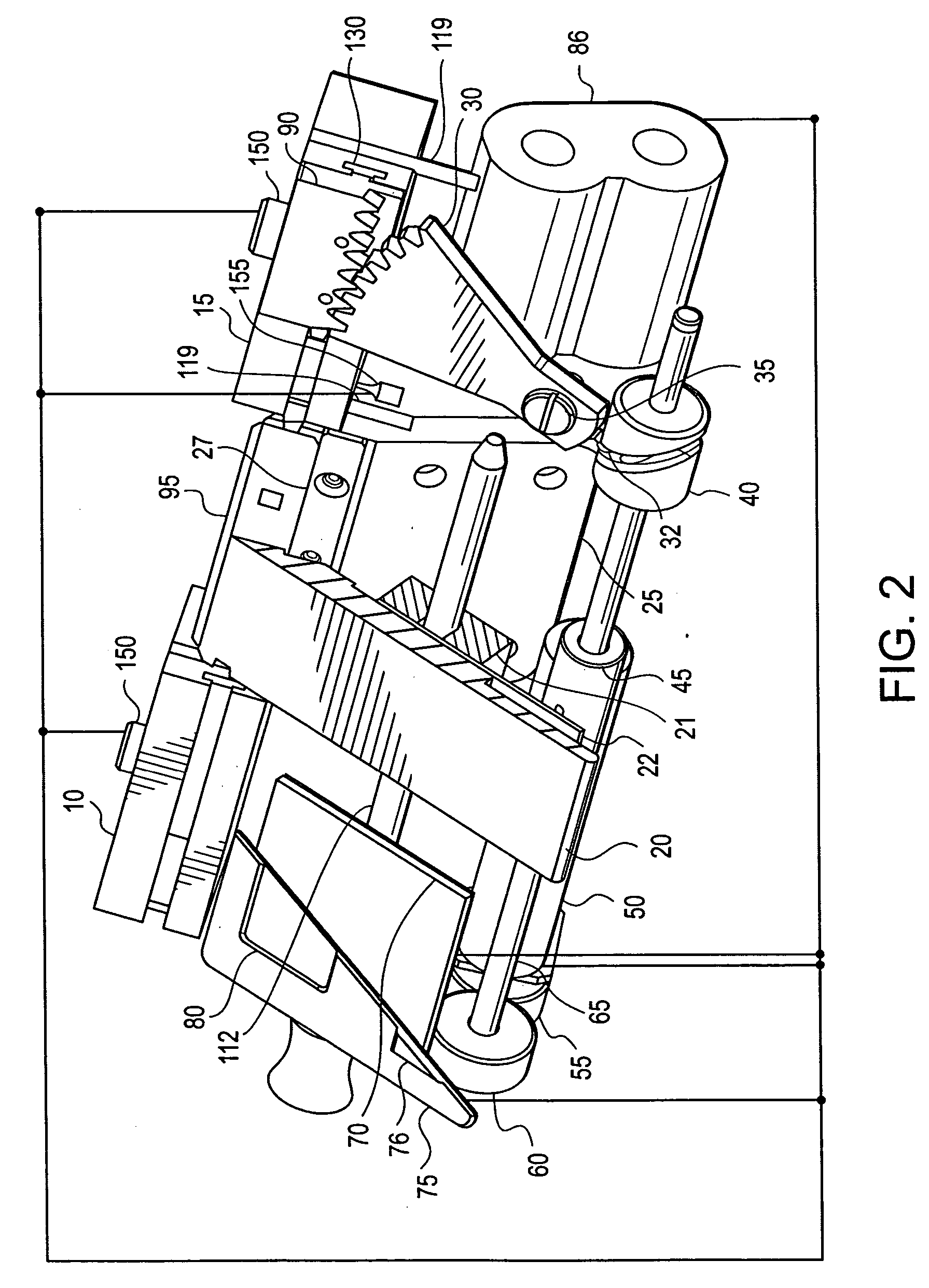

[0031] the blade changer comprises lower and upper stage bodies 1, 5, respectively. With reference to FIG. 1 the microtome blade cartridges are removably located within the upper stage body 5. The lower stage body is adaptable to a wide variety of rotary microtomes, and serves as the common interface mounting for the upper stage. The disposable blade cartridges 10, 15 are adapted to lock into the upper stage body 5 so as to provide an element of safety. The cartridges are described more fully below and in FIGS. 3-5. They are releasable only when the individual blades are fully secured within the body of the cartridge. This “interlock” function can be attained in many ways, however a preferred embodiment includes an on-board microcontroller which monitors the state of operation of the blade changer. When the controller's logic functions determine that no blade edges are exposed, then the clamping plate and / or the cartridges may be released. The interlock function is more fully descri...

second embodiment

[0039] Again with reference to FIG. 3, supply cartridge 15 has a dispensing tab 90 integral with the cartridge and adapted for engaging each new blade 95. Downward protrusion 92 engages a slot or opening in each new blade. The downward protrusion may be a metal tab, a plastic hook or similar equivalent article. The main design limitation is that it reliably contact only one blade at a time. Downward protrusion 92 may be located anywhere on dispensing tab 90 so long as it functions to urge a single blade out of the cartridge for each cycle of the loading segment 30. In the preferred embodiment shown in FIG. 3, the protrusion is forward mounted on the blade side of dispensing tab 90. the dispensing tab is shown in FIGS. 7-8. The primary feature is that dispensing tab shown (290) is designed with a slot or cutout for engaging shuttle tab 231. It does not have the teeth necessary for engaging the loading segment 30, which is not present in this embodiment.

[0040] The safety interlock fea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Semiconductor | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com