Amorphous insoluble cellulosic fiber and method for making same

a technology of soluble cellulosic fiber and dietary fiber, which is applied in the field of processing of dietary fiber, can solve the problems of uneconomical, multiple complex processing steps, and low economic value of recovered solids, and achieves the effect of varying the time, temperature and strength of alkaline treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Refined Corn Bran

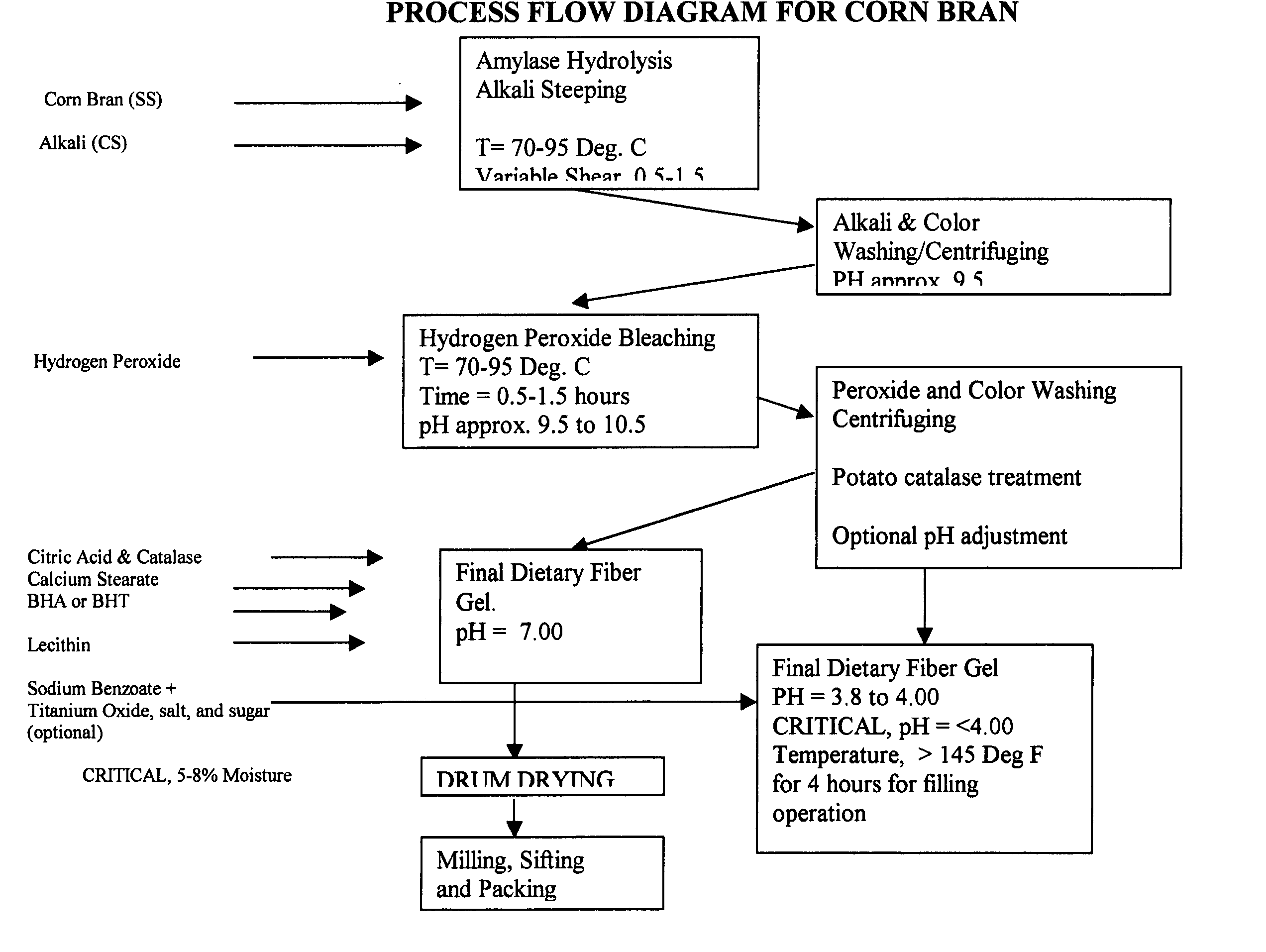

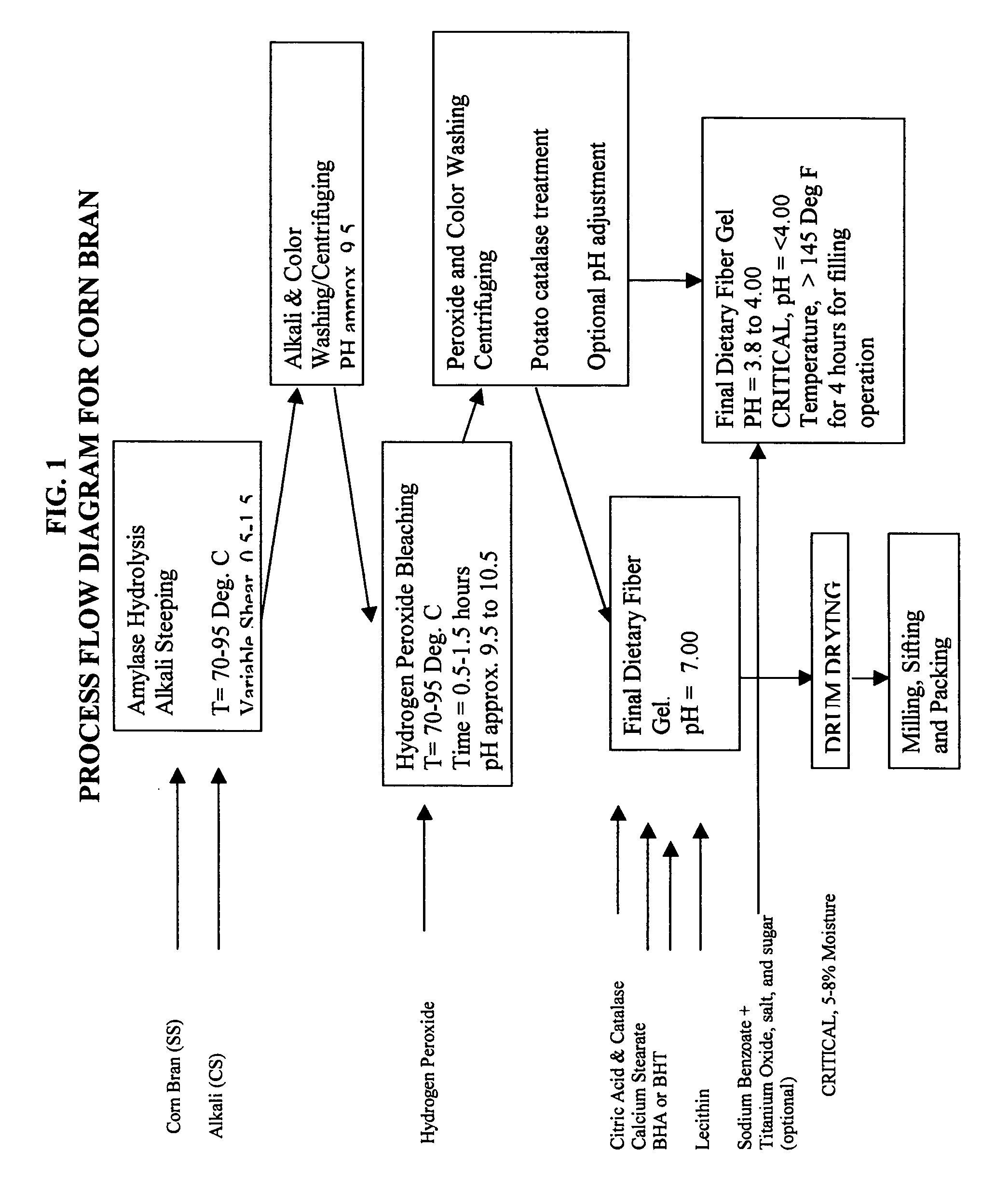

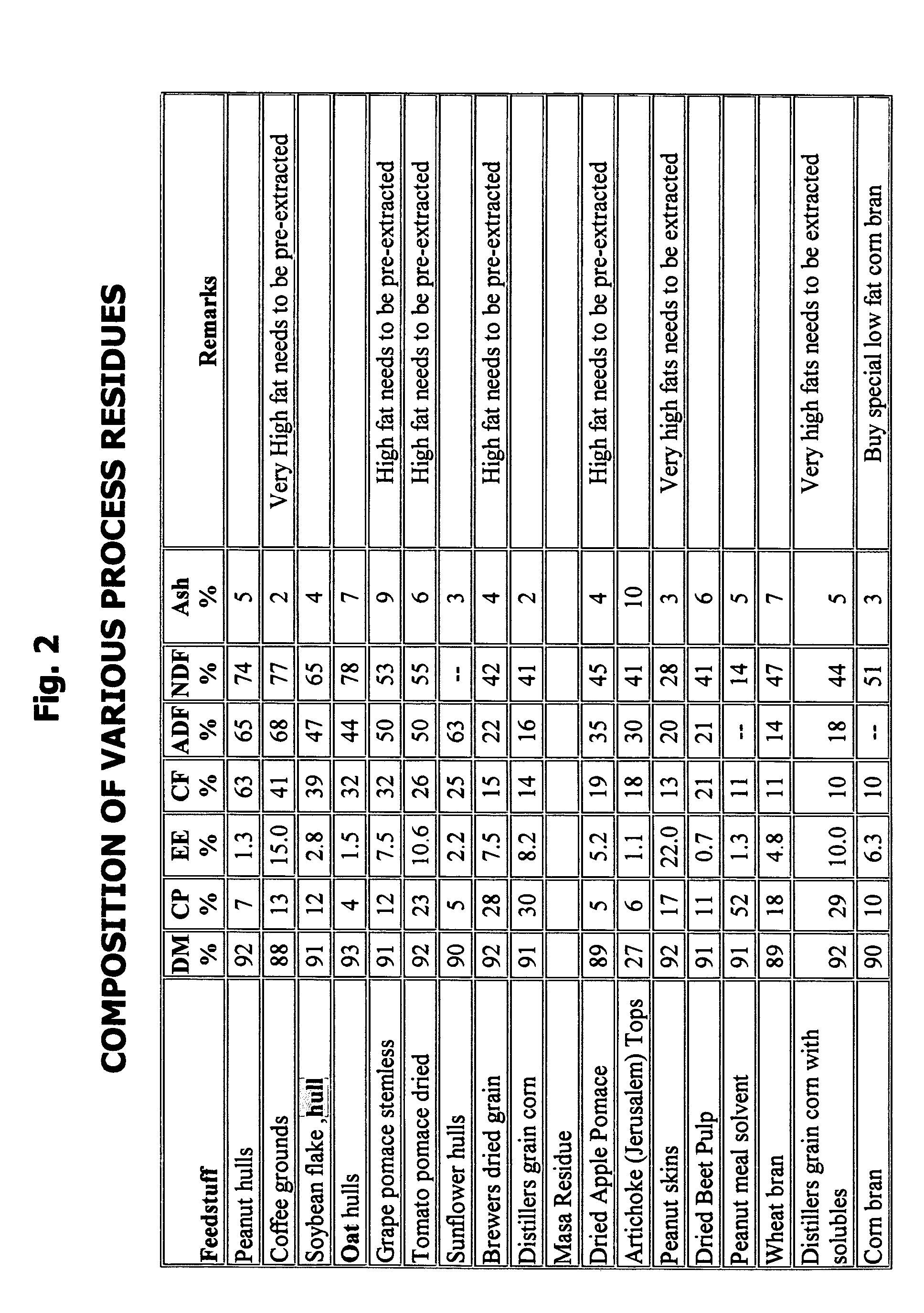

[0045] The process of this example can be used for feedstocks comprising weaker and partially processed fiber, such as refined corn bran. All operations herein are performed under elevated temperatures, 70 degrees Celsius (C.) to 95 degrees C., and under high shear.

[0046] STEP 1: Alkali Steeping. Feedstock can be added to water to form a slurry and steeped in alkali conditions using sodium hydroxide. Alkali concentration can be in the range of 1 to 25 percent of the total weight of the slurry. Steeping can take anywhere from 0.5 hours to 1.5 hours.

[0047] STEP 2: Washing. The slurry can be washed with water until coloration of the slurry is amber. The pH of the slurry should be approximately 9.5.

[0048] STEP 3: Separation. The slurry can be separated, preferably by centrifugation, retaining the fraction comprising substantially insoluble fiber and removing the fraction substantially comprising soluble fiber, protein and ash.

[0049] STEP 4: Bleaching / Oxidation. Oxi...

example 2

Wheat Bran

[0054] The process of this example can be used for feedstocks comprising wheat bran. All operations herein are performed under elevated temperatures, 70 degrees Celsius (C.) to 85 degrees C., and under high shear.

[0055] STEP 1: Alkali Steeping. Feedstock can be added to water to form a slurry and steeped in alkali conditions using sodium hydroxide. Alkali concentration can be in the range of 1 to 25 percent of the total weight of the slurry. Steeping can take anywhere from 0.5 hours to 1.5 hours.

[0056] STEP 2: Washing. The slurry can be washed with water until coloration of the slurry is amber. The pH of the slurry should be approximately 9.5.

[0057] STEP 3: Separation. The slurry can be separated, preferably by centrifugation, retaining the fraction comprising substantially insoluble fiber and removing the fraction substantially comprising soluble fiber, protein and ash.

[0058] STEP 4: Bleaching / Oxidation. Oxidizing agent, preferably hydrogen peroxide, can be added suc...

example 3

Corn Masa Residue

[0063] The process of this example can be used for feedstocks comprising corn masa residue. All operations herein are performed under elevated temperatures, 70 degrees Celsius (C.) to 85 degrees C., and under high shear.

[0064] STEP 1: Alkali Steeping. Feedstock can be added to water to form a slurry and steeped in alkali conditions using sodium hydroxide. Alkali concentration can be in the range of 1 to 25 percent of the total weight of the slurry. Steeping can take anywhere from 1.0 hour to 3.0 hours.

[0065] STEP 2: Washing. The slurry can be washed with water until coloration of the slurry is amber. The pH of the slurry should be approximately 9.5.

[0066] STEP 3: Separation. The slurry can be separated, preferably by centrifugation, retaining the fraction comprising substantially insoluble fiber and removing the fraction substantially comprising soluble fiber, protein and ash.

[0067] STEP 4: Bleaching / Oxidation. Oxidizing agent, preferably hydrogen peroxide, can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com