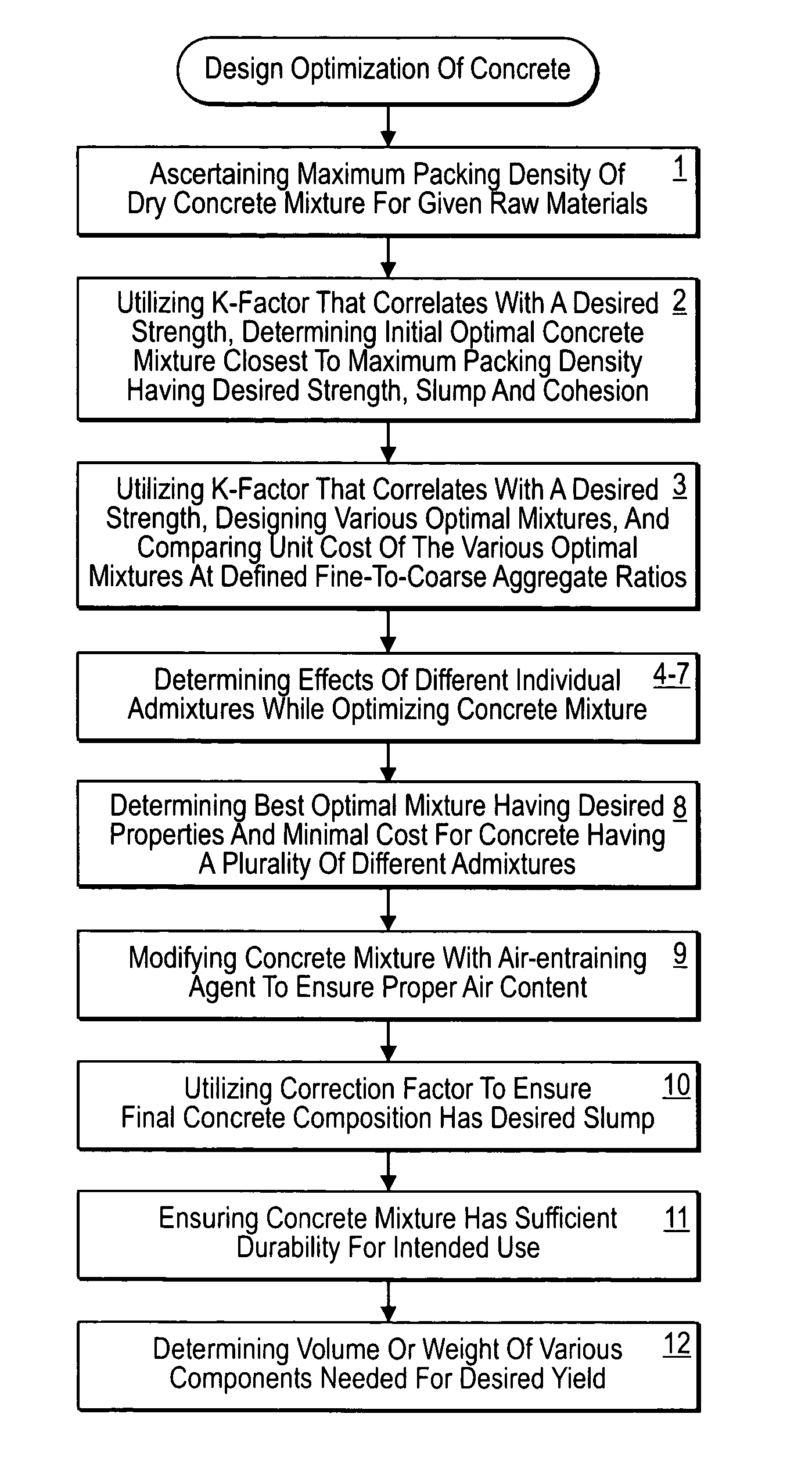

Methods and systems for redesigning pre-existing concrete mix designs and manufacturing plants and design-optimizing and manufacturing concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

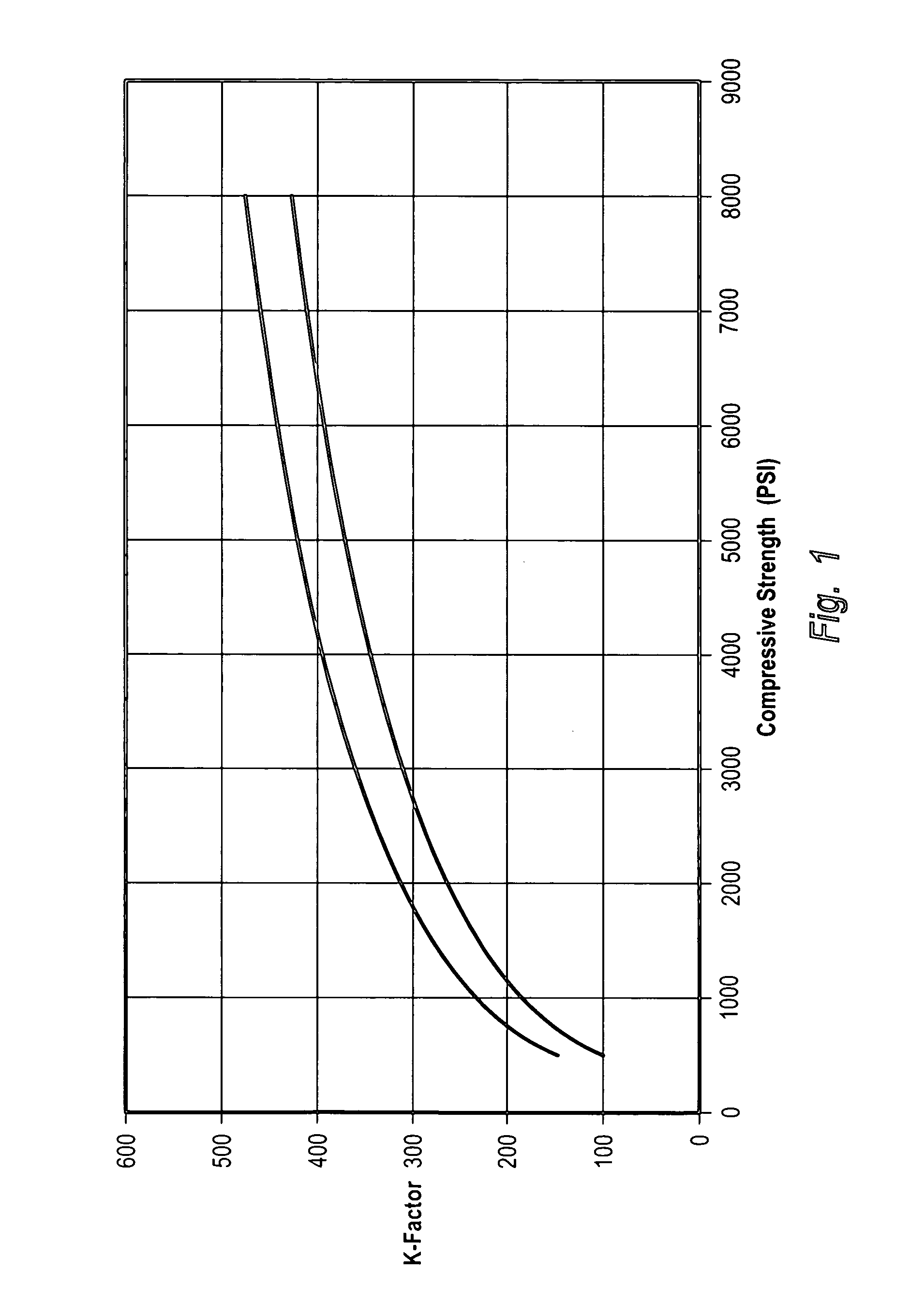

Method used

Image

Examples

examples 1-4

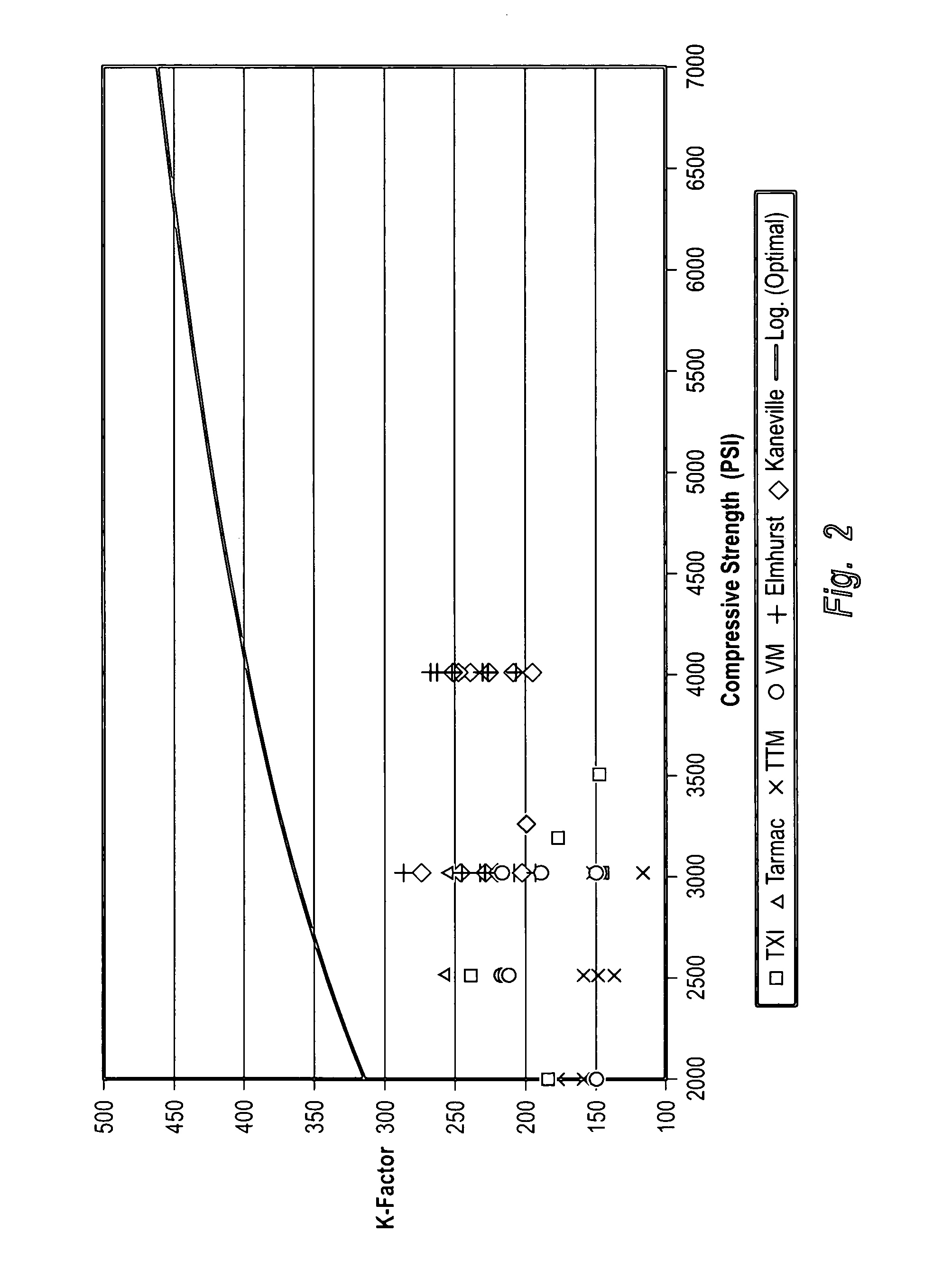

[0324] Examples 1-4 illustrate four optimized concrete mix designs that were prepared using the improved DOC process described herein. The four mix designs of Examples 1-4 can replace twelve pre-existing standard concrete mix designs utilized by an existing concrete manufacturing plant. Each mix design of Examples 1-4 corresponds to a group of three pre-existing mix designs of similar type that guarantee a minimum compressive strength, at a specified slump, and percentage of entrained air when delivered to the customer. The pre-existing mix designs of the concrete manufacturing plant, their components, cost (revised Apr. 7, 2006), and apparent design K factors, will be presented in four groups of three concrete mix designs, each group having similar properties or characteristics.

examples 5-8

[0333] Examples 5-8 illustrate four optimized concrete mix designs that were prepared using the improved DOC process described herein. The four mix designs of Examples 5-8 can replace twelve pre-existing standard concrete mix designs of an existing concrete manufacturing plant, which used the same 12 mix designs as in Comparative Examples 1a-4c but manufactured concrete using a different set of raw materials. Each mix design of Examples 5-8 corresponds to a group of three pre-existing mix designs of similar type that guarantee a minimum compressive strength, at a specified slump, and percentage of entrained air when delivered to the customer. The pre-existing mix designs of the concrete manufacturing plant, their components, cost (revised Oct. 27, 2005), and apparent design K factors, will be presented in four groups of three concrete mix designs, each group having similar properties or characteristics.

examples 9-12

[0341] Examples 9-12 illustrate four optimized concrete mix designs that were prepared using the improved DOC process described herein. The four mix designs of Examples 9-12 can replace twelve pre-existing standard concrete mix designs of an existing concrete manufacturing plant, which used the same 12 mix designs as in Comparative Example 1a-4c but manufactured concrete using a different set of raw materials. Each mix design of Examples 9-12 corresponds to a group of three pre-existing mix designs of similar type that guarantee a minimum compressive strength, at a specified slump, and percentage of entrained air when delivered to the customer. The pre-existing mix designs of the concrete manufacturing plant, their components, cost (revised Oct. 27, 2005), and apparent design K factors, will be presented in four groups of three concrete mix designs, each group having similar properties or characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com