Hydrodynamic closed loop turboset-selfbooster

a closed-loop, self-boostering technology, applied in the direction of liquid fuel engines, machines/engines, stators, etc., can solve the problems of large and costly fuel consumption, low total efficiency of about 40%, harm emissions, etc., to achieve substantial energy dissipation losses, high energy ratio, and harm emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

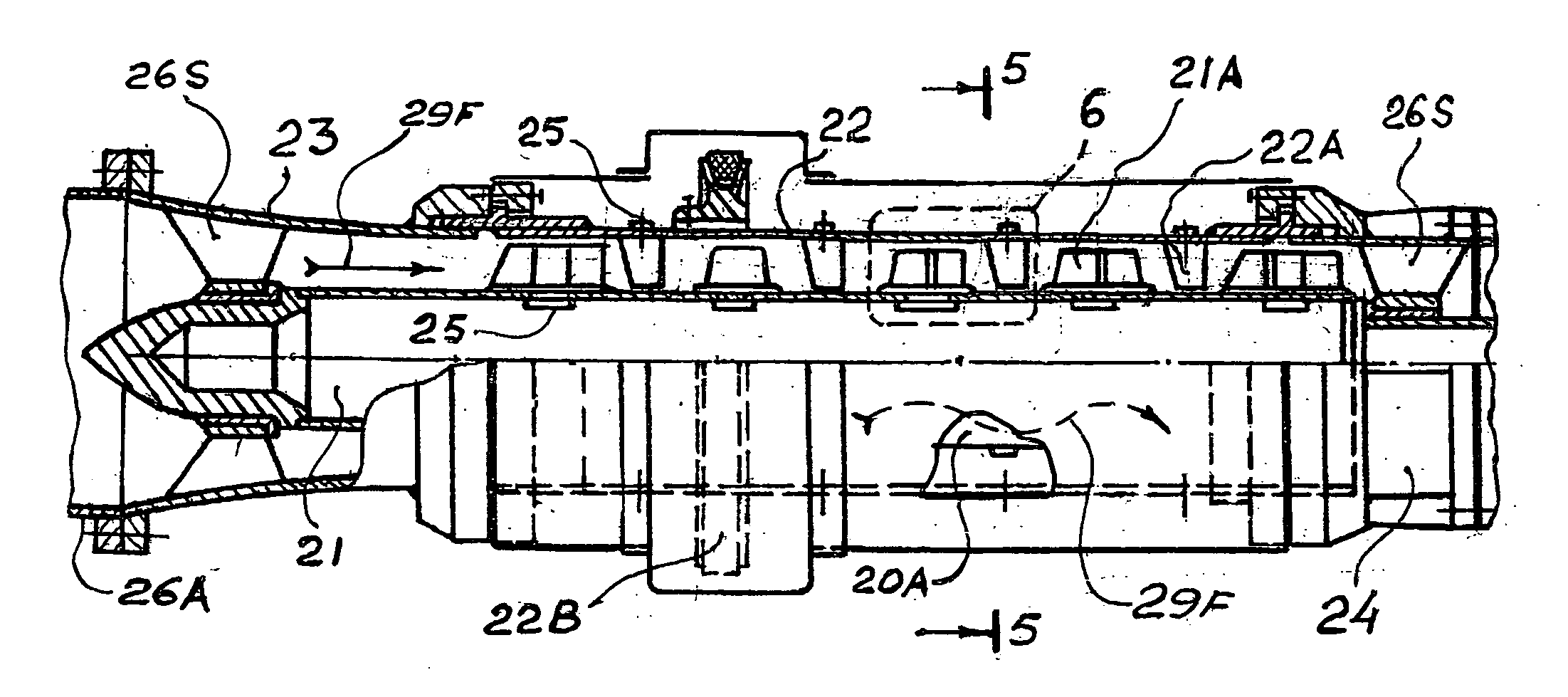

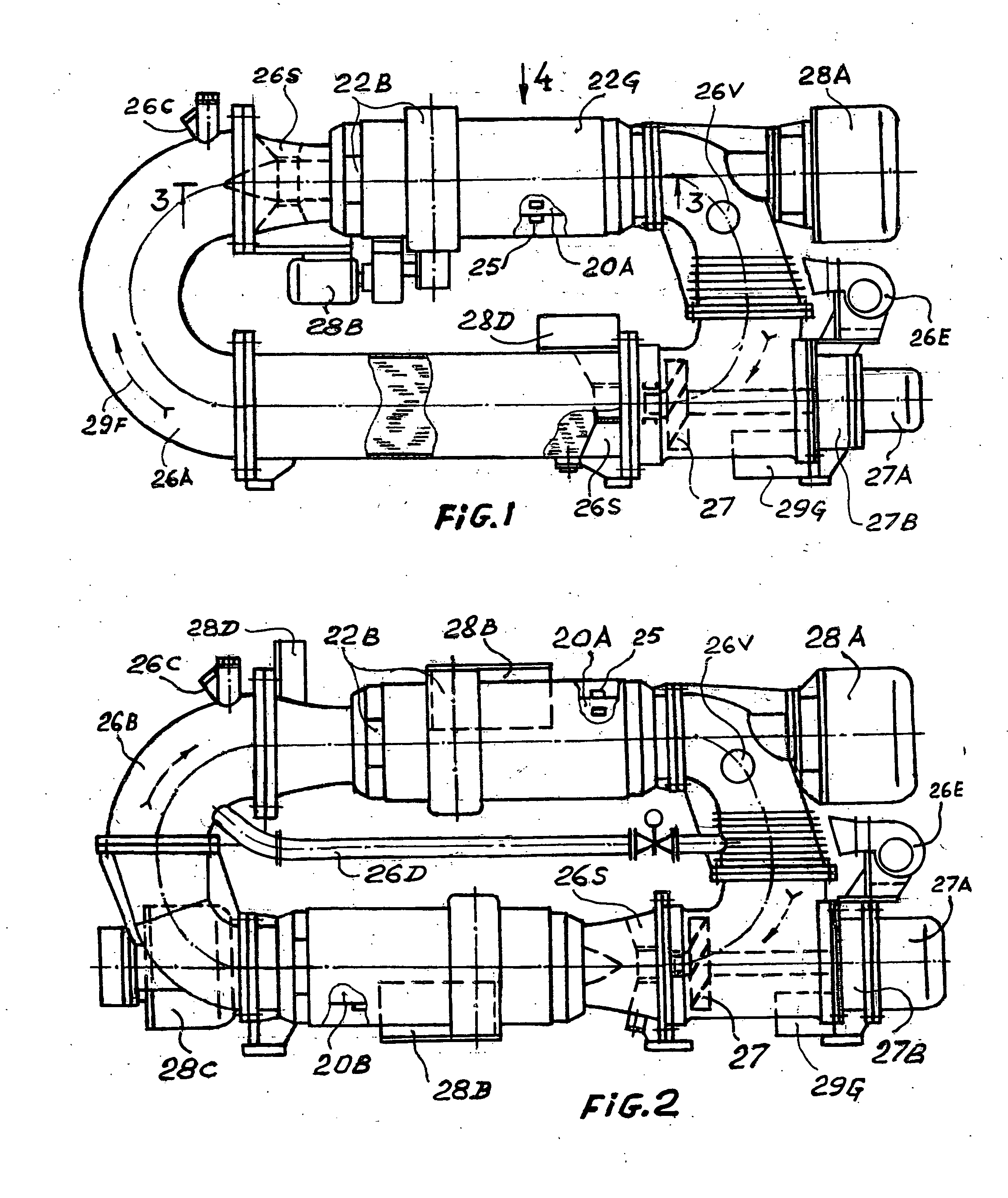

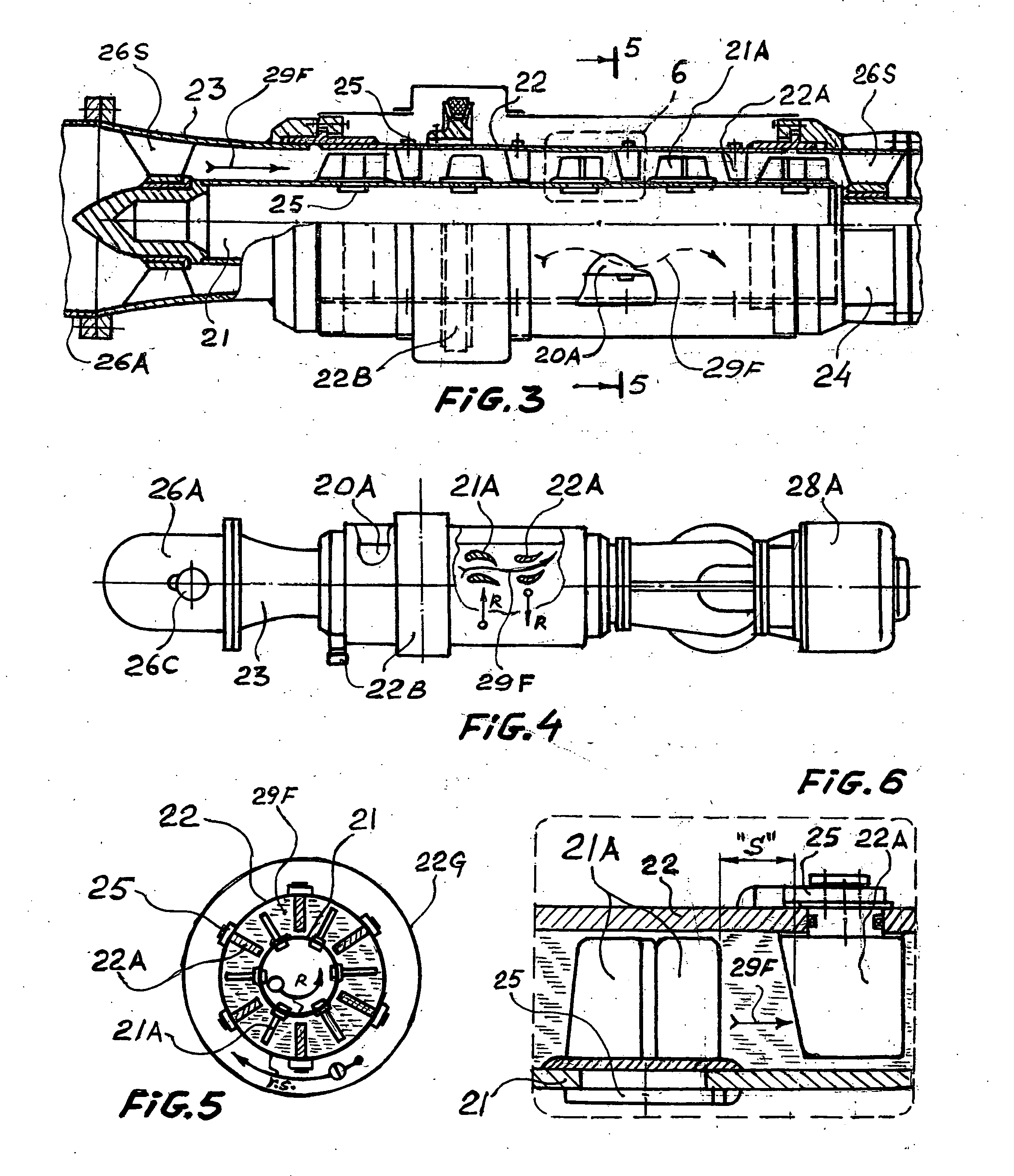

[0059] The FIGS. 1, 2, 3, 4, 5, 6 show the preferred embodiments and arrangements of the present proposal its units, subunits, and their interactions.

[0060] A hydrodynamic closed loop turobset-selfbooster, its turbotechnology as illustrated in FIG. 1 includes at least an axial bispindle hydroturbine 20A installed into closed loop tubular liquid tunnel 26A with an axial-flow propeller pump 27. The definite amount of operative liquid which is completely filled into said tunnel is preferably a high density operative liquid under definite controlled static pressure. The hydroturbine 20A being bispindle drive two electric generators 28A and 28B by each spindle and could drive any other receivers of turbine's power in other designs. The turboset has a tunnel air-cooler 26E placed near cooling fins of the tunnel 26A, a kit of needed hydraulic and electric meters and general control panel 29G.

[0061] Another, a cascade embodiment of this proposal is hown in FIG. 2 where two axial bispindle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com