A battery using bromine-containing ionic liquid as a positive electrode active material and its assembly method

An ionic liquid and battery technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of slow kinetics and inactivity, achieve high specific energy, mature production technology, and prolong cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

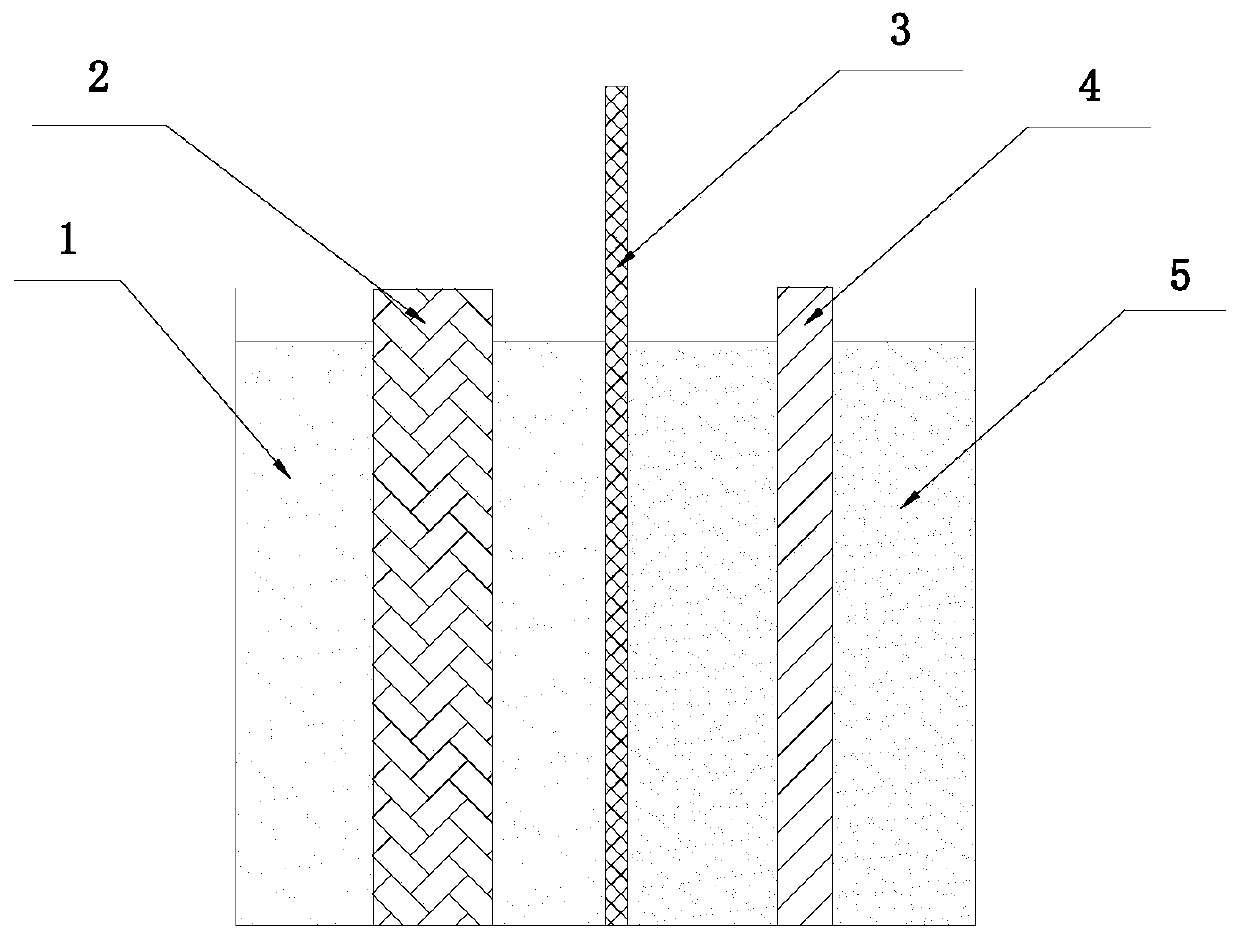

[0054] A battery includes a positive electrode chamber and a negative electrode chamber separated by a Nafion membrane; the electrolyte in the positive electrode chamber includes tetraethylammonium tribromide, and the negative electrode chamber is injected with an ionic liquid electrolyte; carbon nanotubes are inserted into the positive electrode chamber The positive electrode, the negative electrode chamber is immersed with an aluminum negative electrode.

[0055] The ionic liquid electrolyte is prepared by mixing anhydrous aluminum chloride and 1-ethyl-3-methyl-imidazolium chloride in a molar ratio of 2:1.

[0056] The assembling method of the battery specifically includes the following steps:

[0057] (1) The carbon nanotube positive electrode, tetraethylammonium tribromide, and ionic liquid electrolyte are placed in a glove box filled with argon;

[0058] (2) Use Nafion membrane and sealing ring for lamination and assembly;

[0059] (3) Insert the positive electrode of t...

Embodiment 2

[0061] Compared with Example 1, the Selemion film was used instead of the Nafion film, and the others were the same as in Example 1.

Embodiment 3

[0063] Compared with Example 1, Daramic film was used instead of Nafion film, and the others were the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com