Method and device for producing synthesis by partial oxidation of slurries made from fuels containing ash with partial quenching and waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

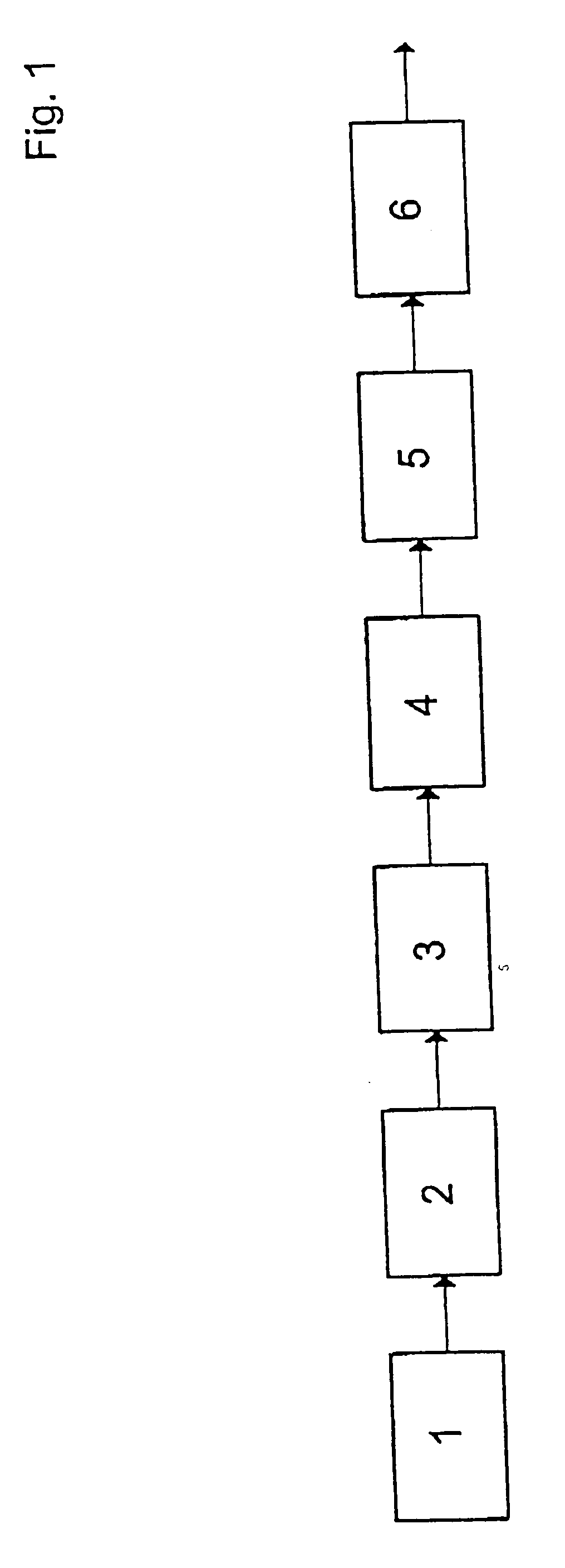

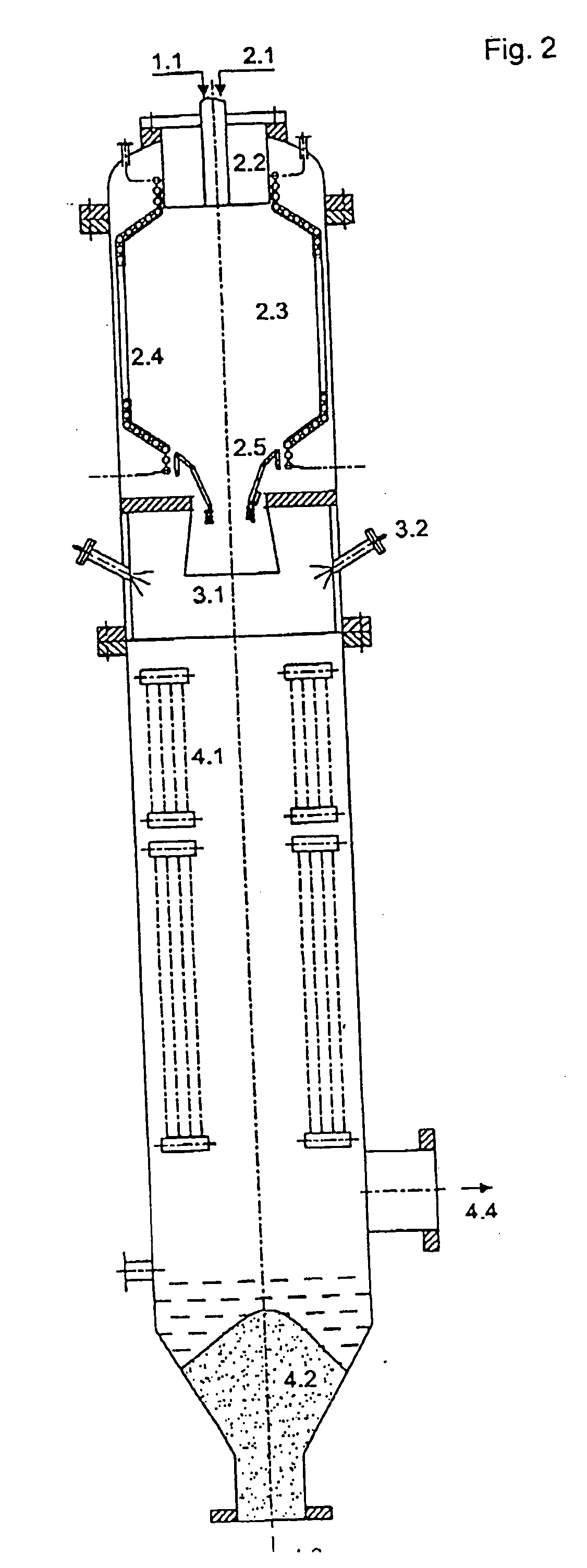

[0022] 320 tons / hour of bituminous coal with a composition of

C71.5 wt. % H4.2 wt. %O9.1 wt. %N0.7 wt. %S1.5 wt. %Cl0.03 wt. %,

an ash content of 11.5 wt. %, and a moisture content of 7.8 wt. %, is to be gasified at a pressure of 40 bar. The calorific value of the coal is 25,600 kJ / kg. The gasification takes place at 1,450° C. 245,000 m3 (standard) / h of oxygen is needed for the gasification. The coal is first fed to a state-of-the-art grinder in which it is pulverized to a grain size range between 0 and 200 μm, and is then mixed in a special system 1 according to FIG. 1 with water with added surfactants to make a stable coal dust in water suspension, the so-called slurry. The solids concentration in this slurry is 63 wt. %, and the amount of slurry is 485 tons / hour. The slurry is brought to the desired gasification pressure of 100 bar by means of a pump suitable for pumping solid-liquid suspensions, and is fed to the burner of the gasification reactor 2 of FIG. 1 through the suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com