System and method of foamed cementitious construction

a cementitious construction and foam technology, applied in the field of construction methods and materials, can solve the problems of concrete, less than optimal thermal insulation, and certain structural elements of reinforced concrete, and achieve excellent thermal and sound insulation, reliable strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Best Modes for Carrying Out the Invention

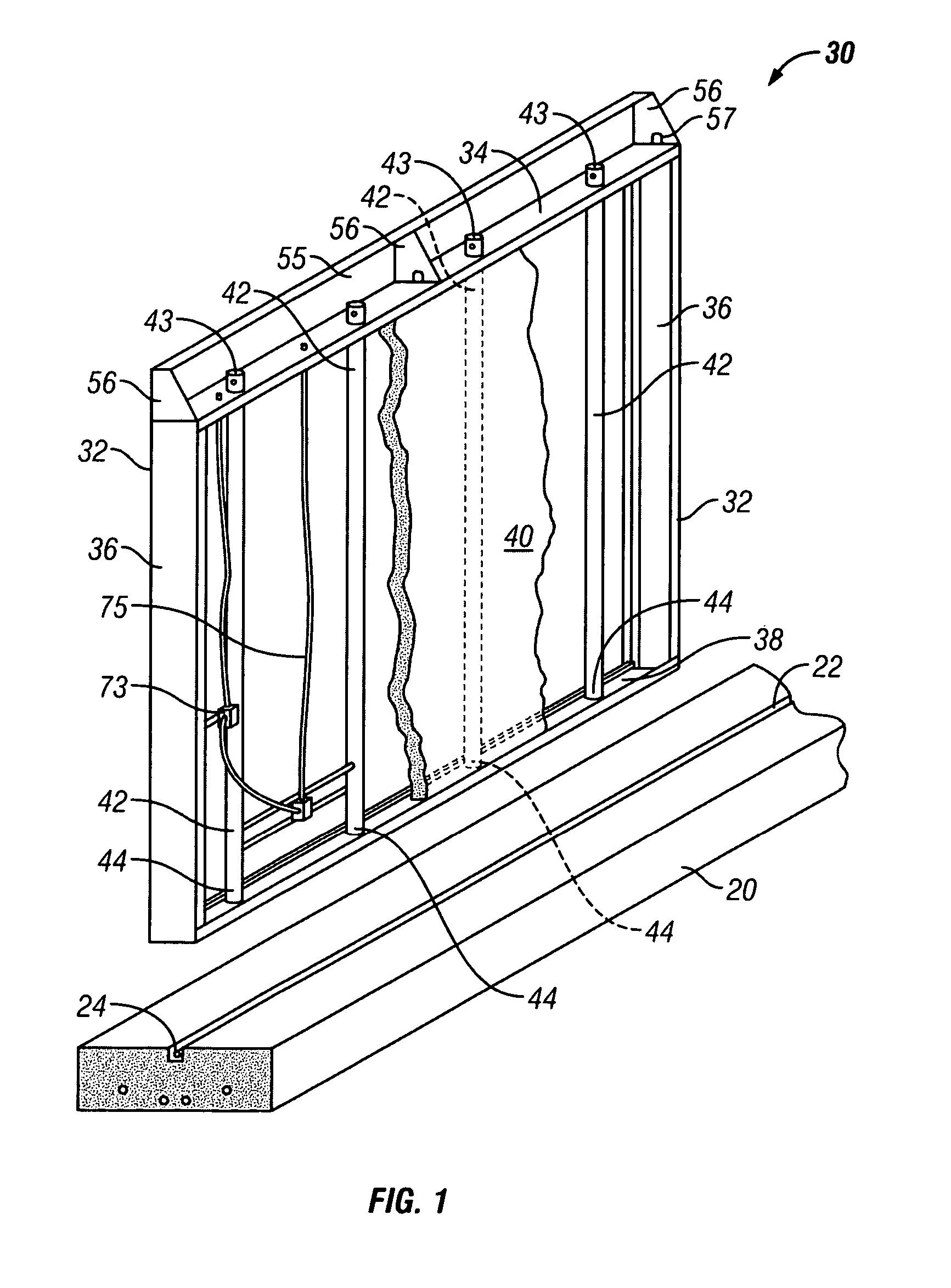

[0038] There is disclosed hereby a construction system and methods for erecting structures, especially including but not limited to residential dwellings of either single- or multiple-family types. The information of the present disclosure is most readily understood in the context of constructing a single-family home; however, it is to be understood that the principles and teachings hereof may be adapted to the erection of nearly any type of building, including commercial and industrial structures. Teachings are offered for a system and method of construction. A lightweight foamed cementitious composition also is disclosed from which structural elements may be fabricated.

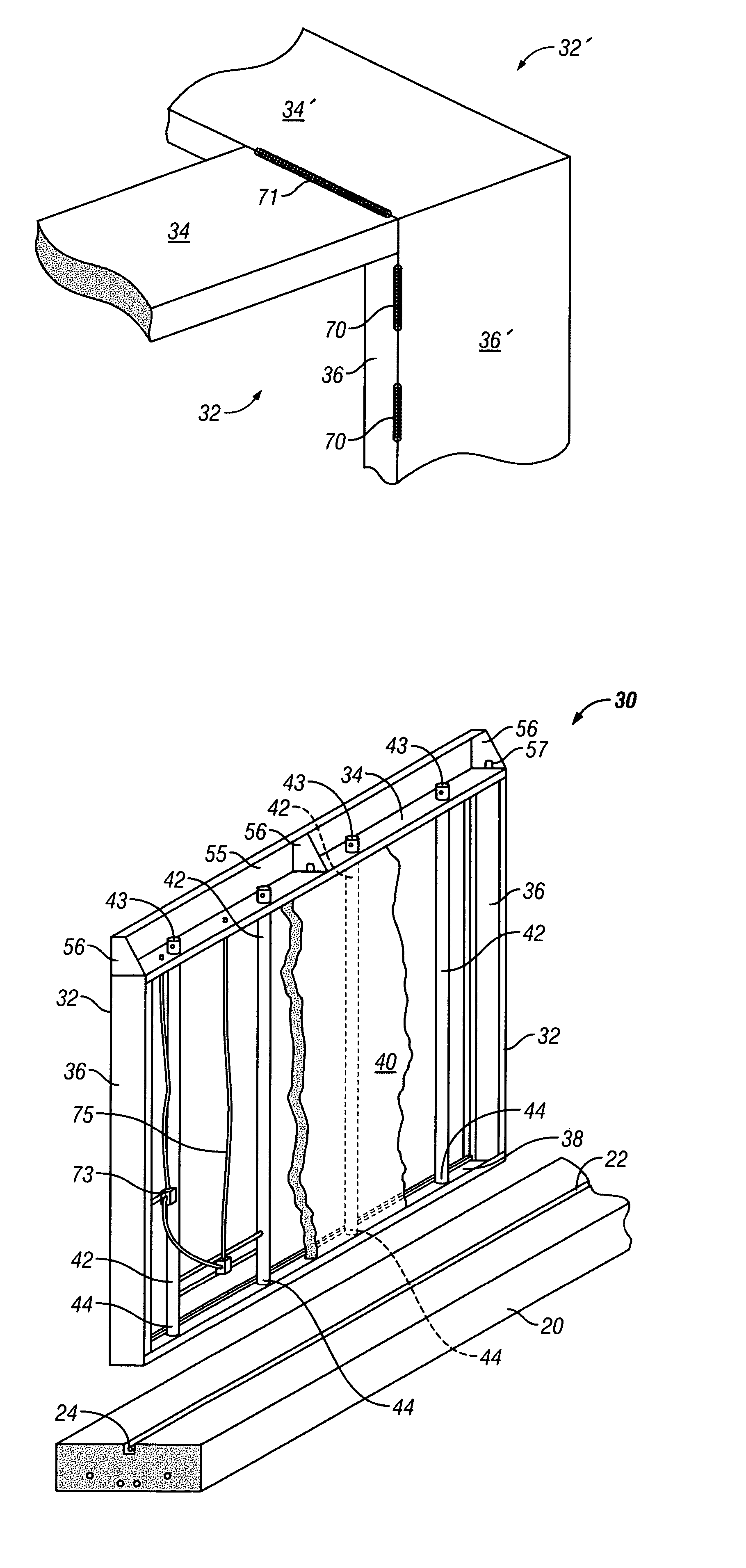

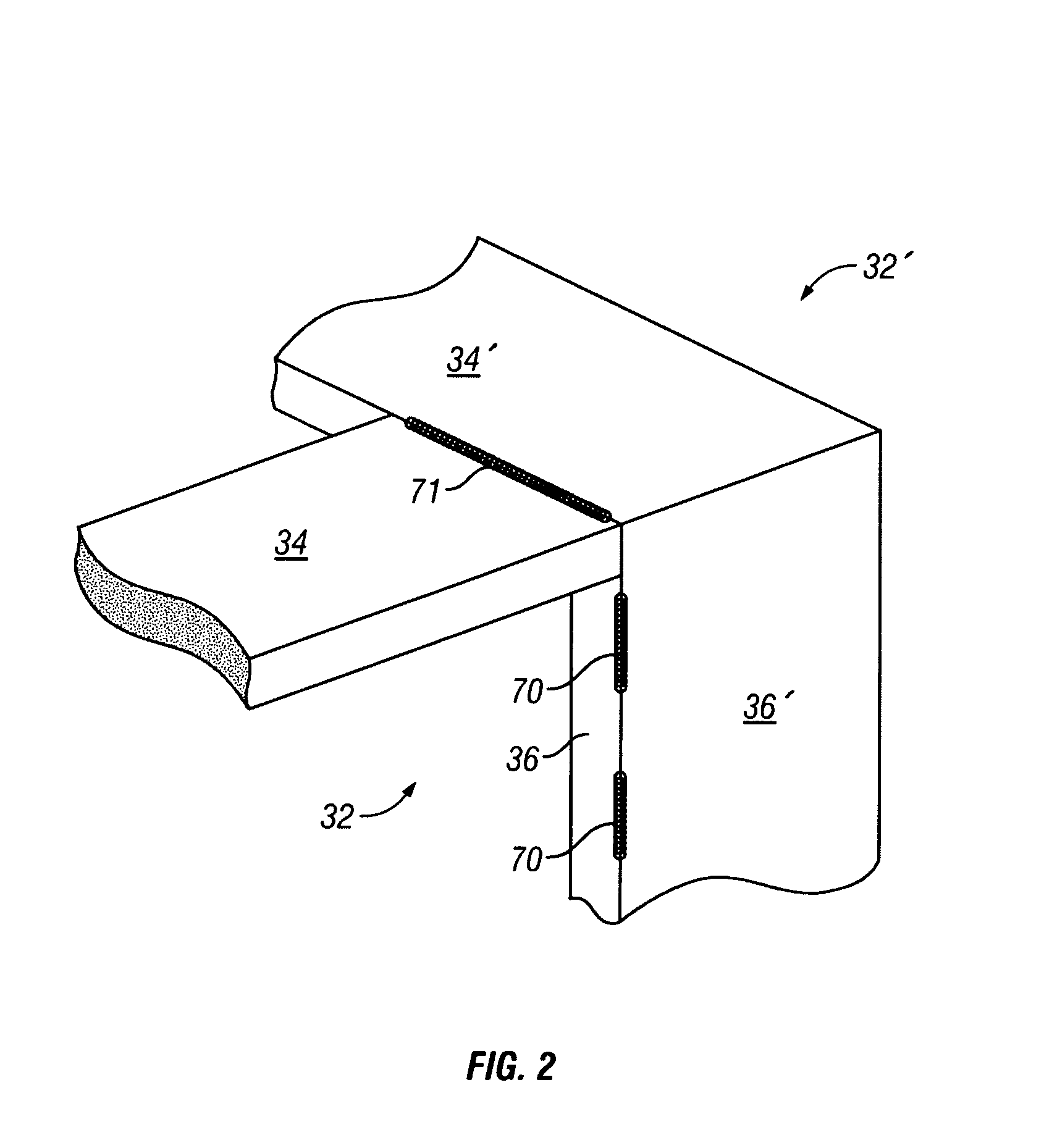

[0039] The building system and method of erection employ a somewhat modular approach, whereby a plurality of panel components are fabricated and then assembled at the building site. Fundamental panel components are fabricated, either on- or off-site, for subsequent installa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com