Exhaust manifold for internal combustion engine

a technology for exhaust manifolds and internal combustion engines, which is applied in the direction of engines/engines, machines/engines, mechanical apparatus, etc., can solve the problems of reduced fuel consumption in a rated horsepower point, long load application time(load making time), and reduced acceleration performance, so as to achieve the effect of reducing load application time and achieving the same effect or advantag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

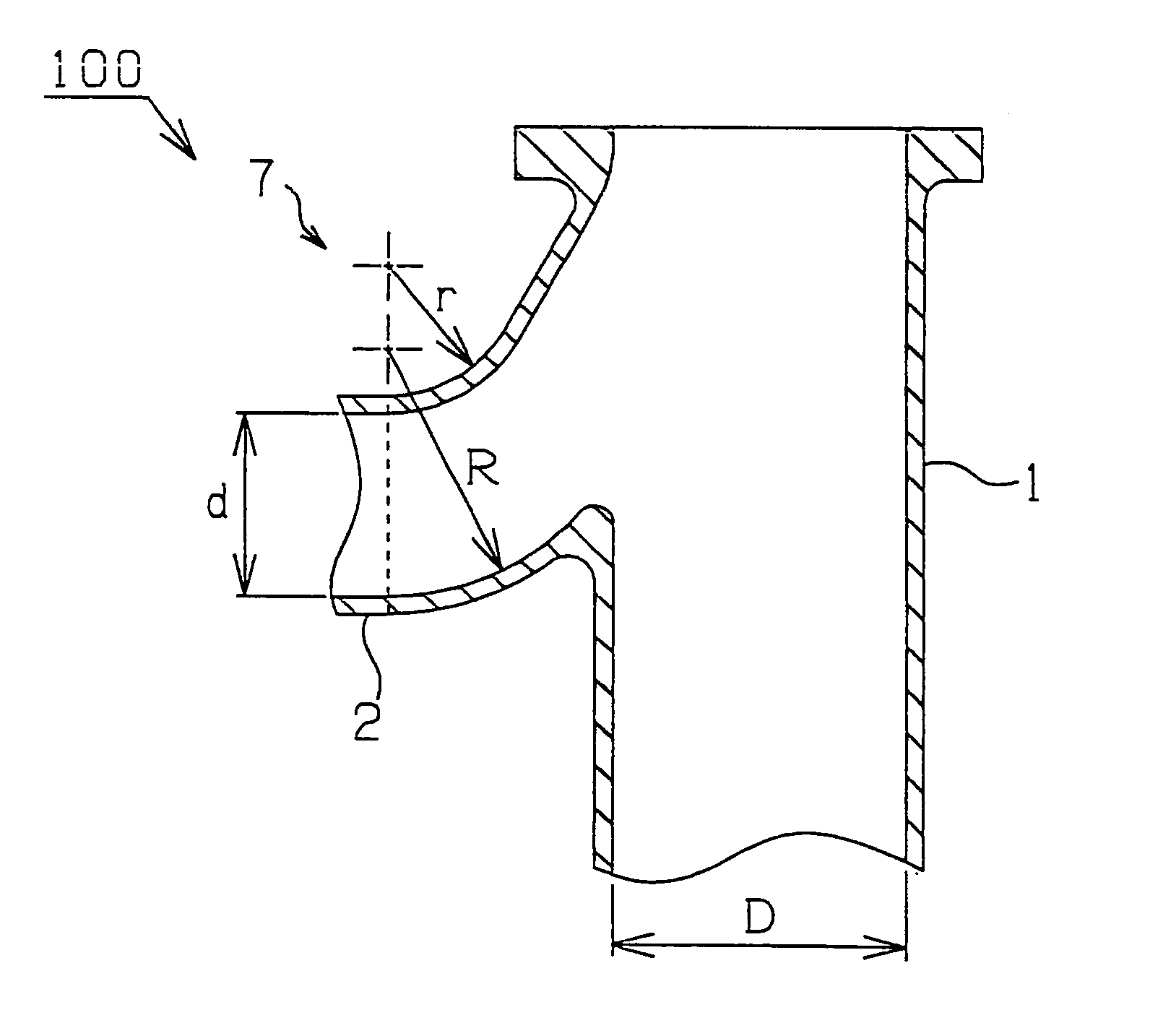

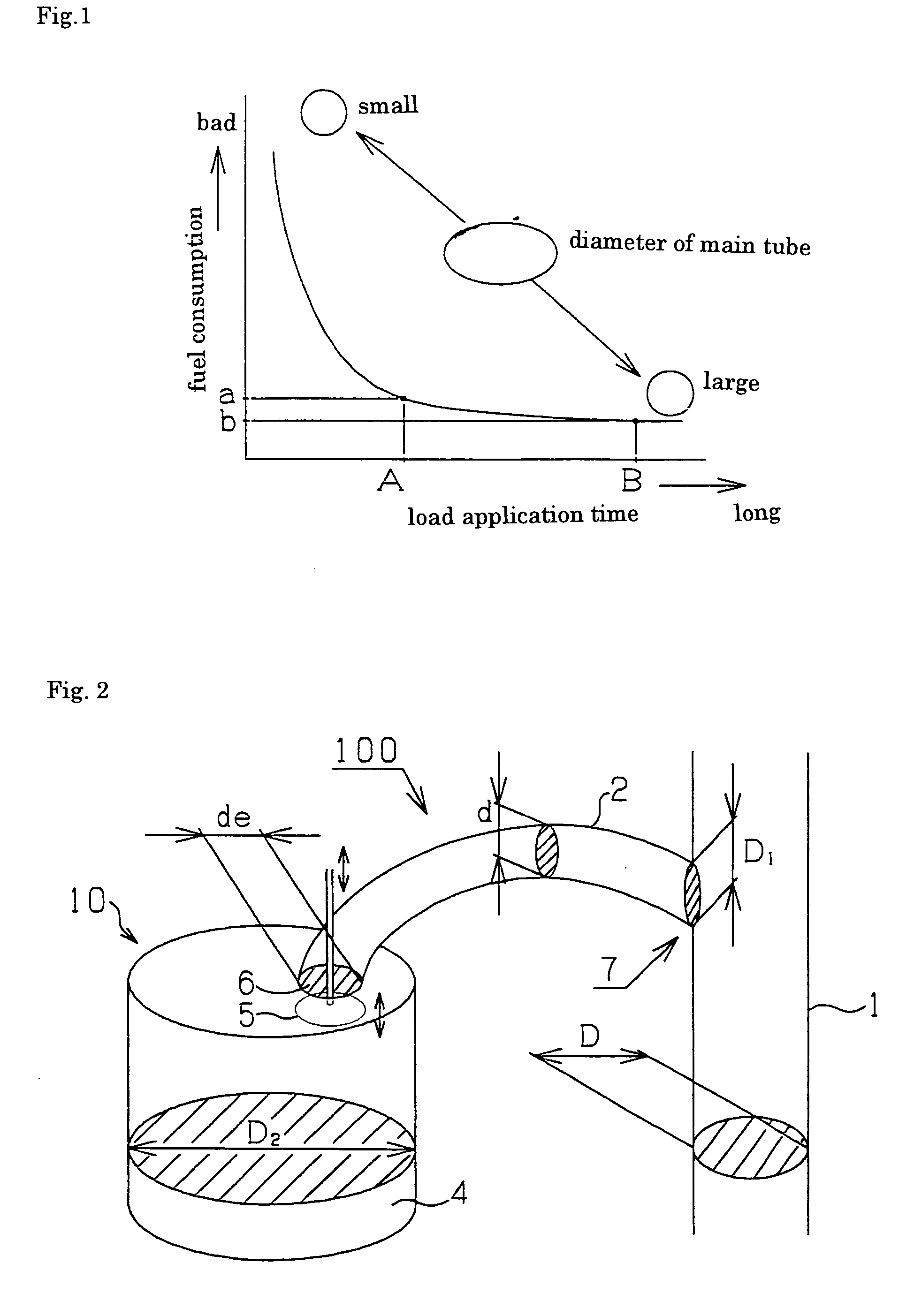

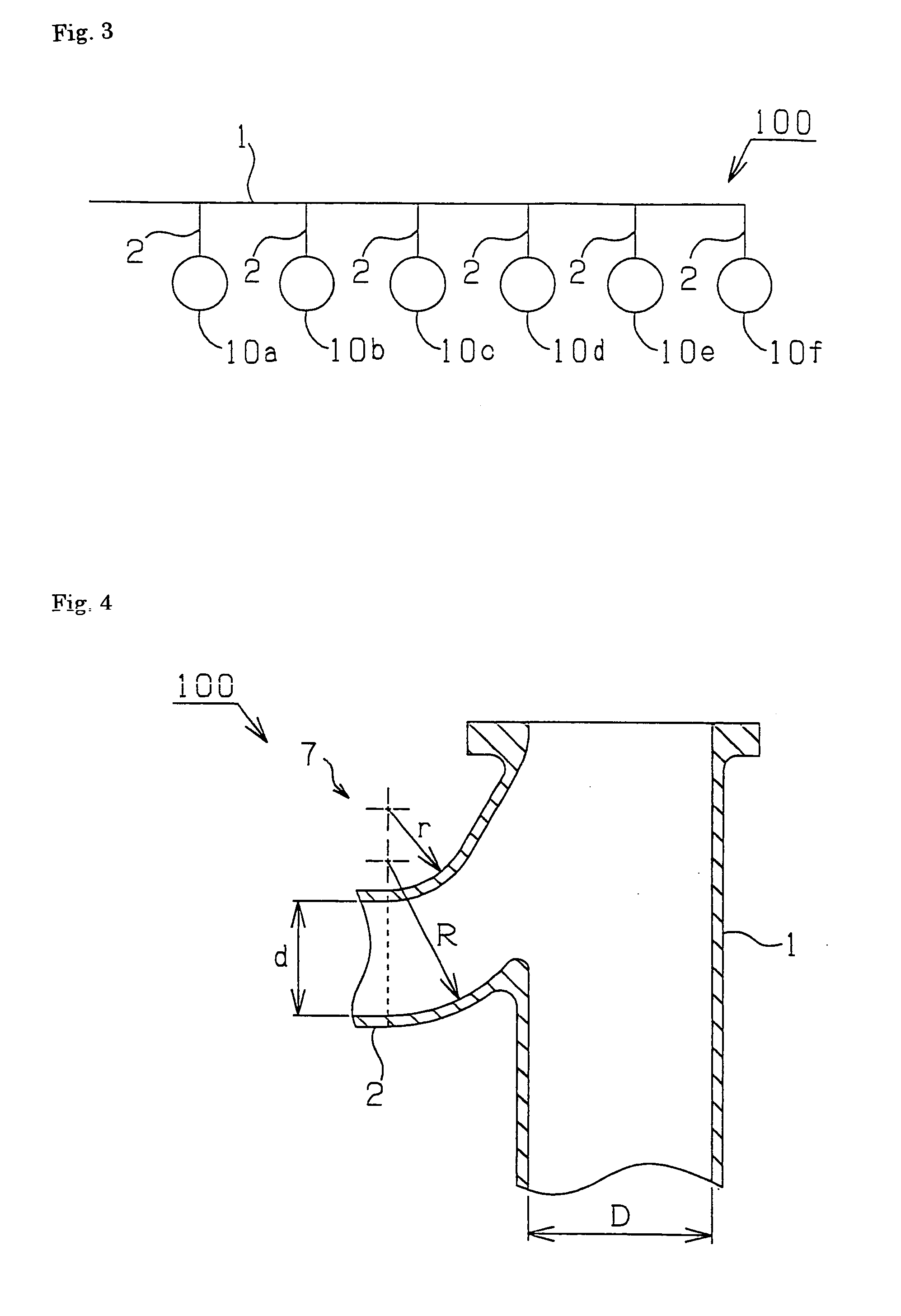

[0034]FIG. 2 is a schematic appearance view of the exhaust manifold of the internal combustion engine according to the present invention. As for the exhaust manifold 100, one end of a branch tube 2 is connected to a side wall of a main tube 1. Another end of the branch tube 2 is connected to an exhaust port 6 of a cylinder 10. An exhaust valve 5 is arranged in the exhaust port 6 so as to be movable in the direction of the arrow. The exhaust port 6 can be opened and closed with the exhaust valve 5. As shown in FIG. 3, a structure of the exhaust manifold 100 is simplified by connecting each cylinder 10a-10f to a main tube 1 via each branch tube 2.

[0035] As shown in FIG. 2, at first, the dimension of the suitable diameter de of an exhaust valve sheet corresponding to the diameter D2 of a boa, which is equivalent to a diameter of a piston 4, is determined. The diameter d of the branch tube 2 is set up so that its dimension may not change rapidly from the diameter de of the exhaust valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com